BOG and oil gas combined recovery system and process method

A recovery system and process method technology, applied in the field of gas engineering, can solve problems such as energy waste, achieve the effect of reasonable configuration and avoid ineffective dissipation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

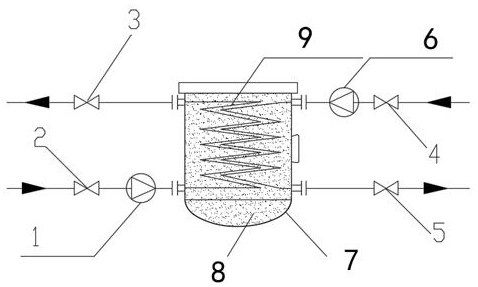

[0014] see figure 1 , embodiments of the present invention include:

[0015] A combined recovery system of BOG and oil and gas, comprising: gas pump 1, first valve 2, second valve 3, third valve 4, fourth valve 5, oil and gas pump 6, filled with diethylene glycol aqueous solution 8, and inside is The cool-storage heat exchanger 7 of the double-helical coil 9; the first valve 2 is connected to the BOG pipeline generated by the LNG storage tank, the inlet of the gas pump 1 is connected to the first valve 2, and the gas pump 1 The outlet is connected to the cold storage heat exchanger 7, the cold storage heat exchanger 7 is connected to the fourth valve 5, the fourth valve 5 is connected to the oil outlet pipeline, and the third valve 4 is connected to the oil gas inlet The pipelines are connected, the third valve 4 is connected to the inlet of the oil-air pump 6, the outlet of the oil-air pump 6 is connected to the cool-storage heat exchanger 7, and the cool-storage heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com