Boiler low grade residual heat combined reclamation method and device

A recovery device, low-grade technology, applied in separation methods, chemical instruments and methods, preheating, etc., can solve the problems of not mentioning the purpose of recovering steam, the steam contains many impurities, and the versatility is not enough, and achieves good social benefits, The effect of reducing pollution and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

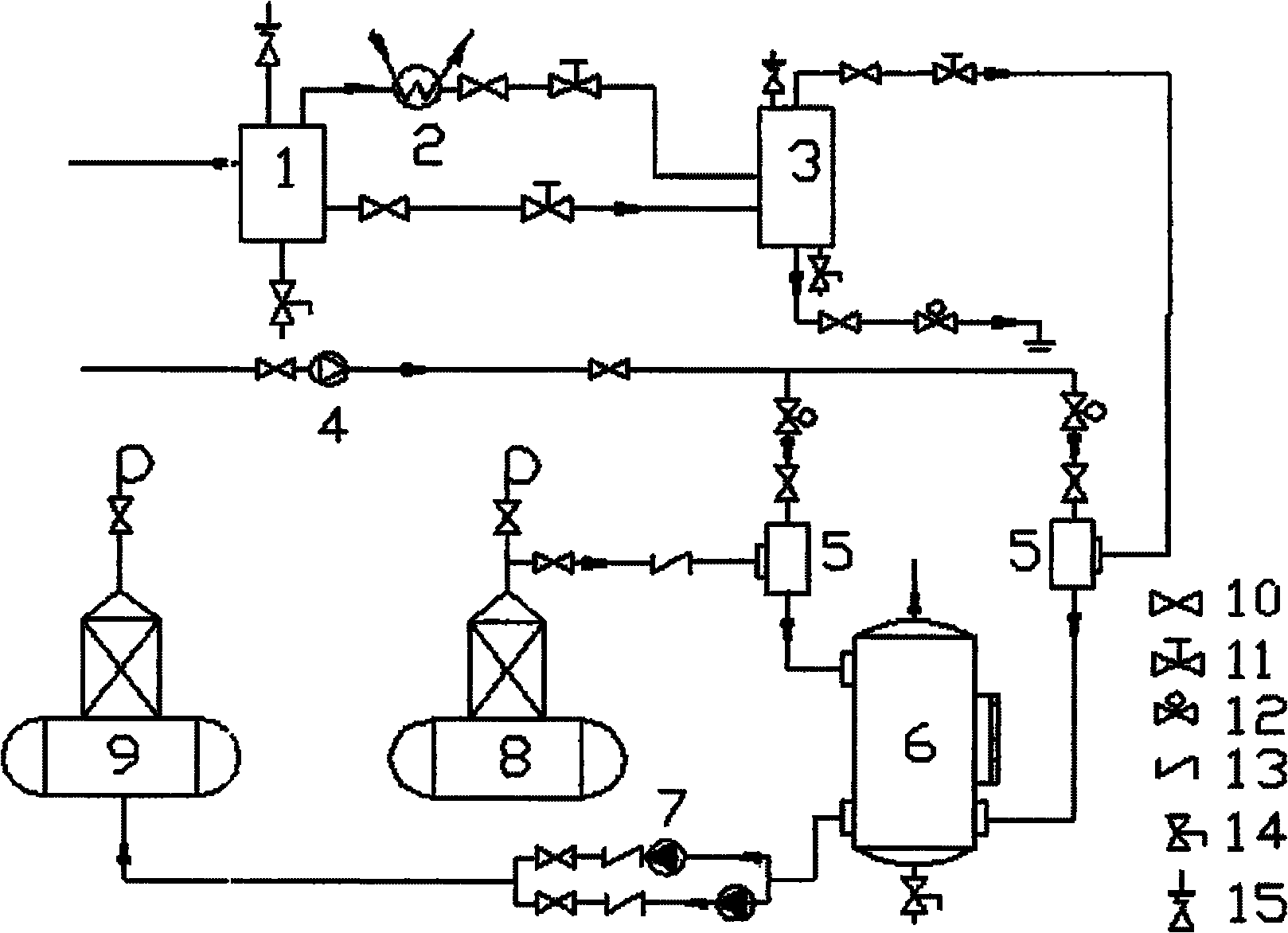

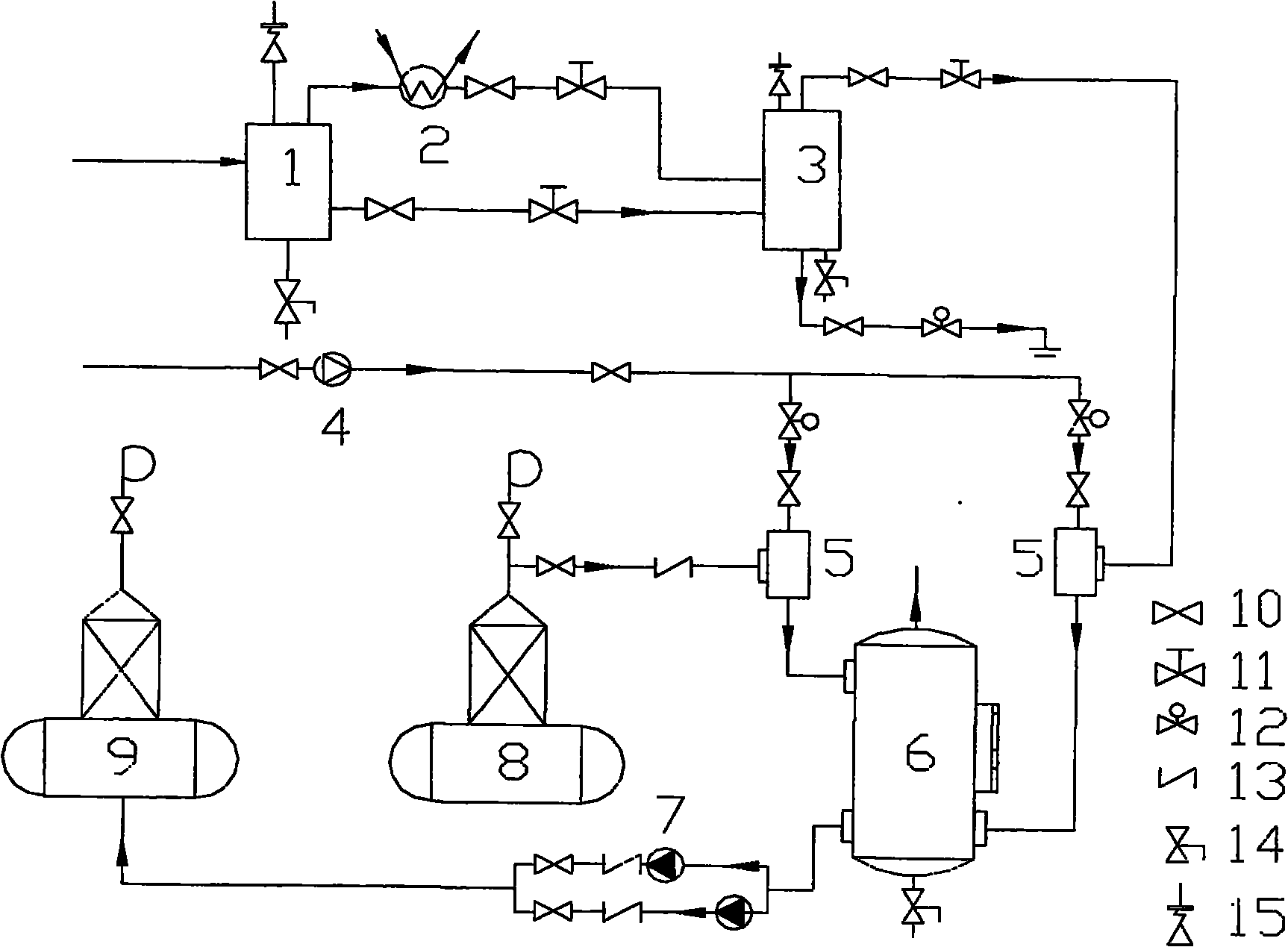

[0014] Such as figure 1 As shown, the drainage of the continuous expansion vessel (1) and the hot water after the flash steam in the continuous expansion vessel is used by the heat user (2) are sent to the flash tank (3) to promote its secondary flash evaporation. The steam that comes out enters the jet mixing heater (5), and the softened water sent by the softening water pump (4) passes through the nozzle of the jet mixing heater (5), and the flow rate increases and the pressure decreases, which will generate a suction effect on the steam. During the mixing process, the steam is condensed and its temperature rises to 90°C, and it enters the degassing water storage tank (6) driven by the residual speed of the injection. The temperature of the flash-evaporated wastewater in the flash tank (3) is lowered and discharged into the ditch. A solenoid valve (12) is installed in the sewage pipeline, and the opening of the solenoid valve is controlled by the liquid level control system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com