Full-blast cooled coal gas generator

A gas generator and generator technology, which is applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of heat waste and inability to handle phenolic water, and achieve the effects of reducing pollution, reducing coal consumption and improving combustion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

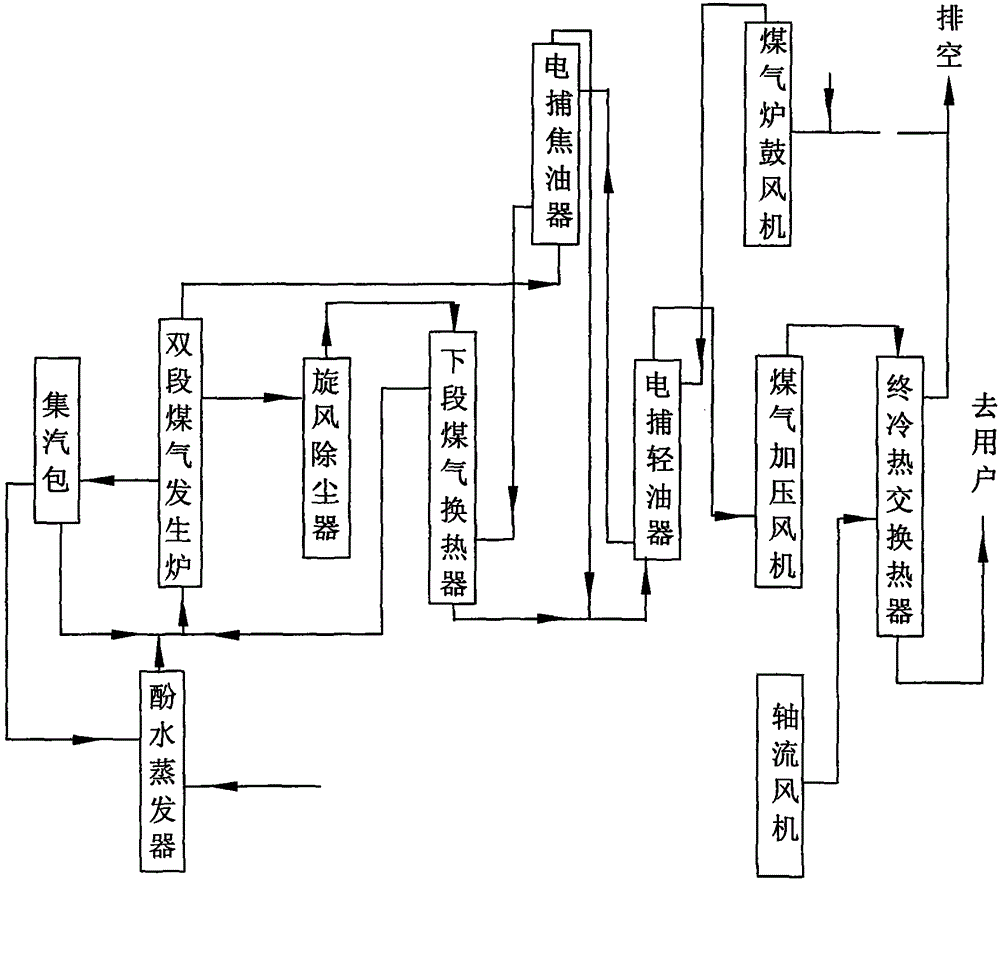

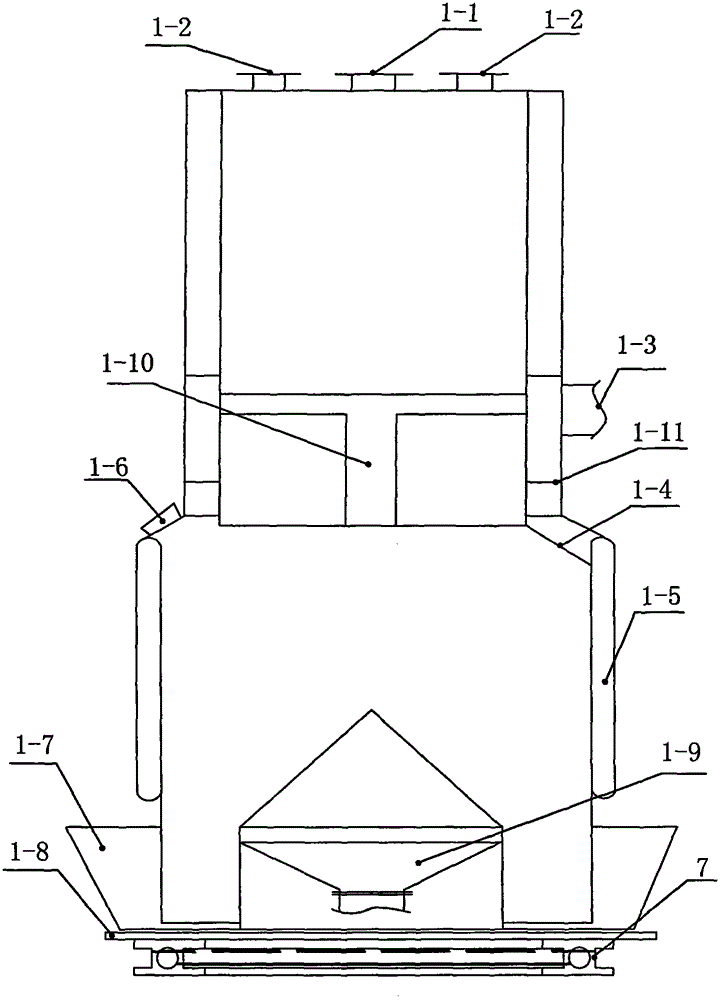

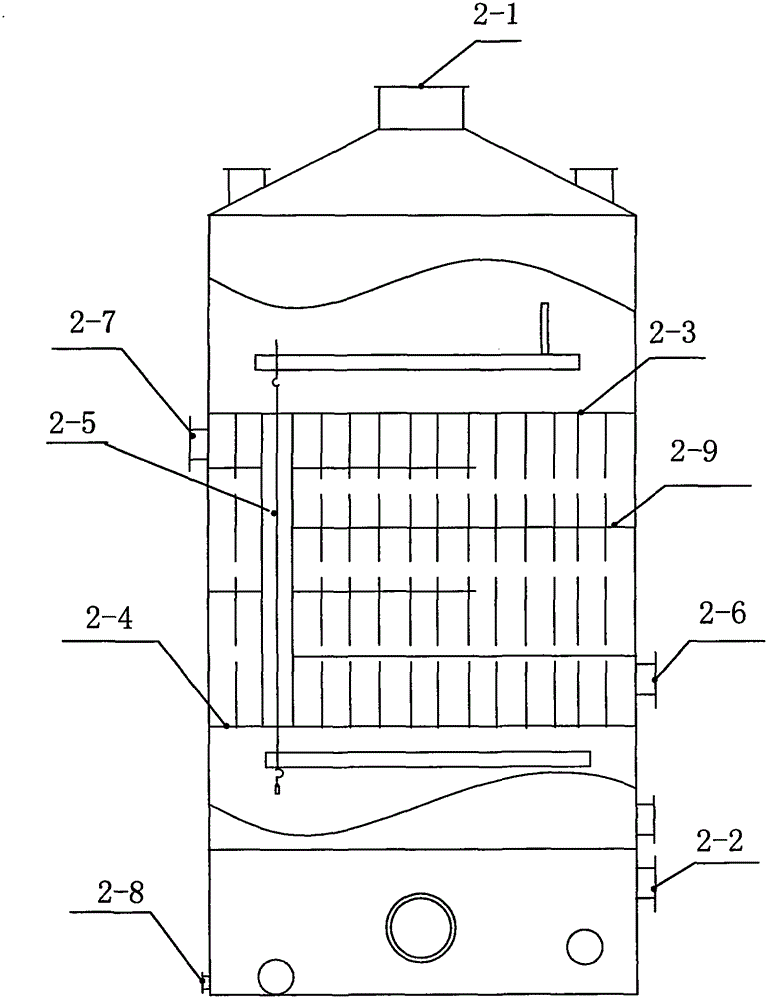

[0029] like figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, the present invention is a full air-cooled gas generator, comprising a double-stage gas generator 1, a cyclone dust collector 9, an electric tar catcher 2, an electric Light oil catcher 3, steam collecting drum 13, also includes lower gas heat exchanger 4, gas pressurization fan 10, final cooling heat exchanger 5, axial flow fan 12, gas furnace blower 11, phenol water evaporator 6, double The gas outlet 1-3 of the lower stage gas generator 1 is connected with the cyclone dust collector 9 and the gas inlet 4-1 of the gas heat exchanger 4 of the lower stage, and the gas outlet 4-2 of the gas heat exchanger 4 of the lower stage is connected with the electric light oil trap The gas inlet II3-1 of the device 3 is connected, the gas outlet II3-2 of the electric light oil catcher 3 is connected with the gas inlet 5-1 of the gas pressure fan 10, the final cooling heat exchanger 5, and the final cooling heat exchanger 5 The cold air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com