Washing machine with drying function

A washing machine and function technology, applied in the field of washing machines with drying function, can solve the problems of increasing power consumption cost, reducing drying efficiency, wasting resources and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

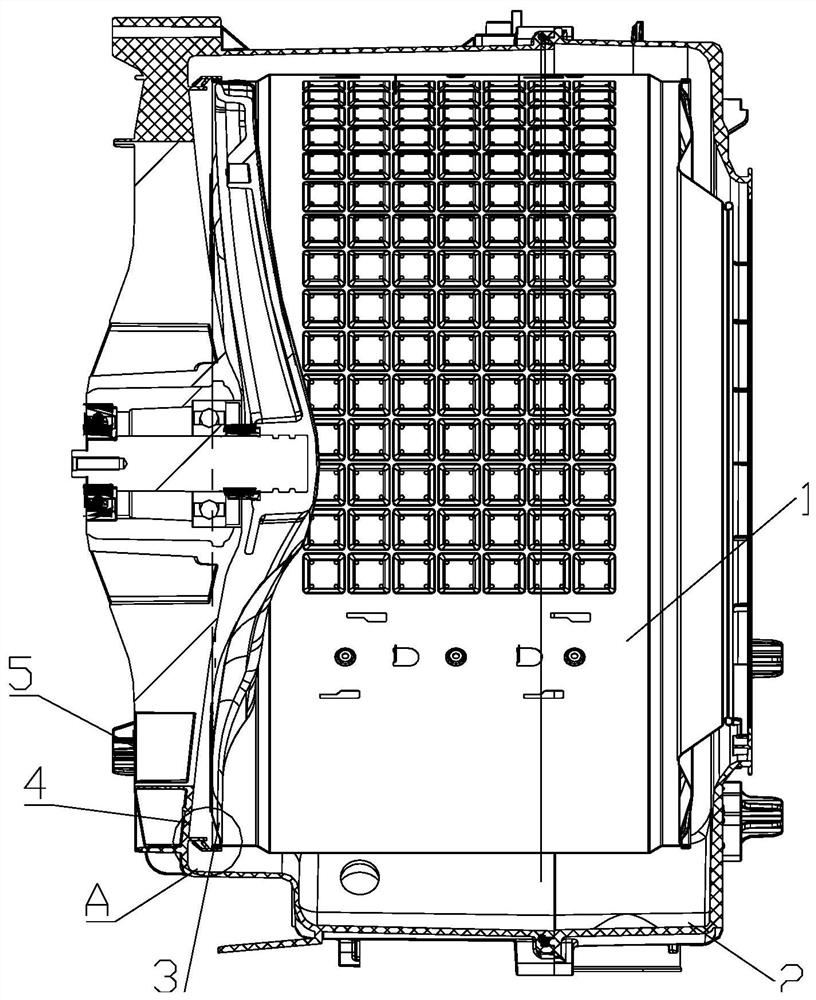

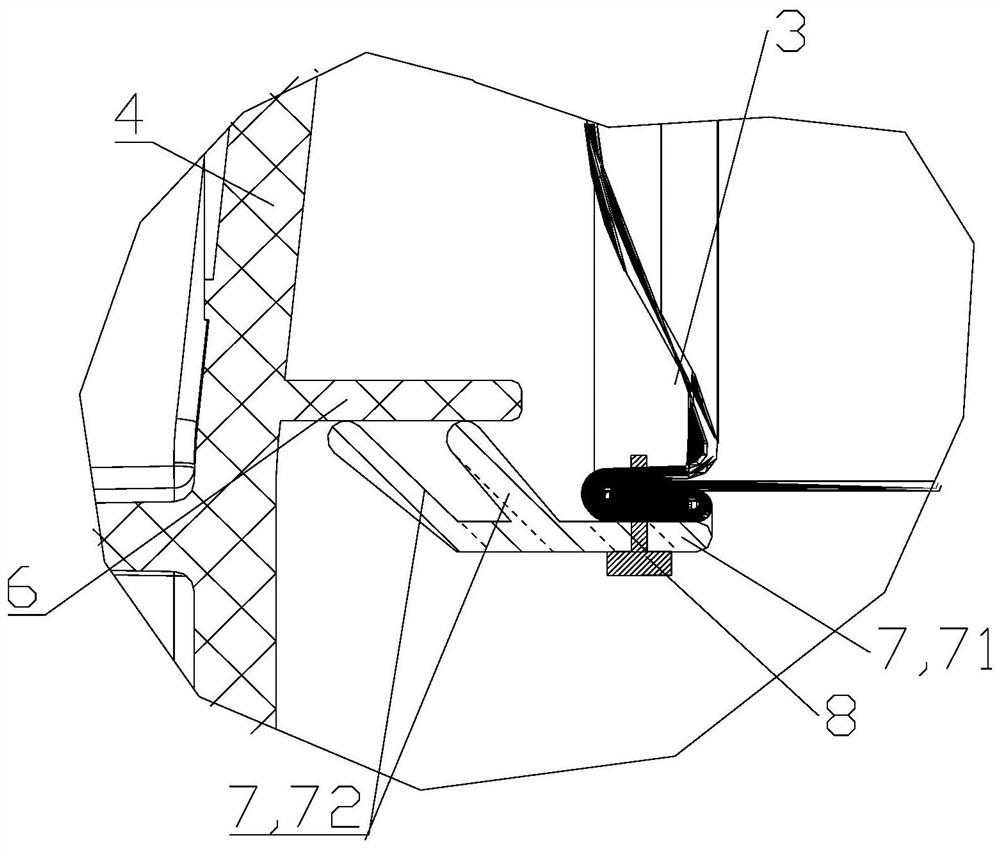

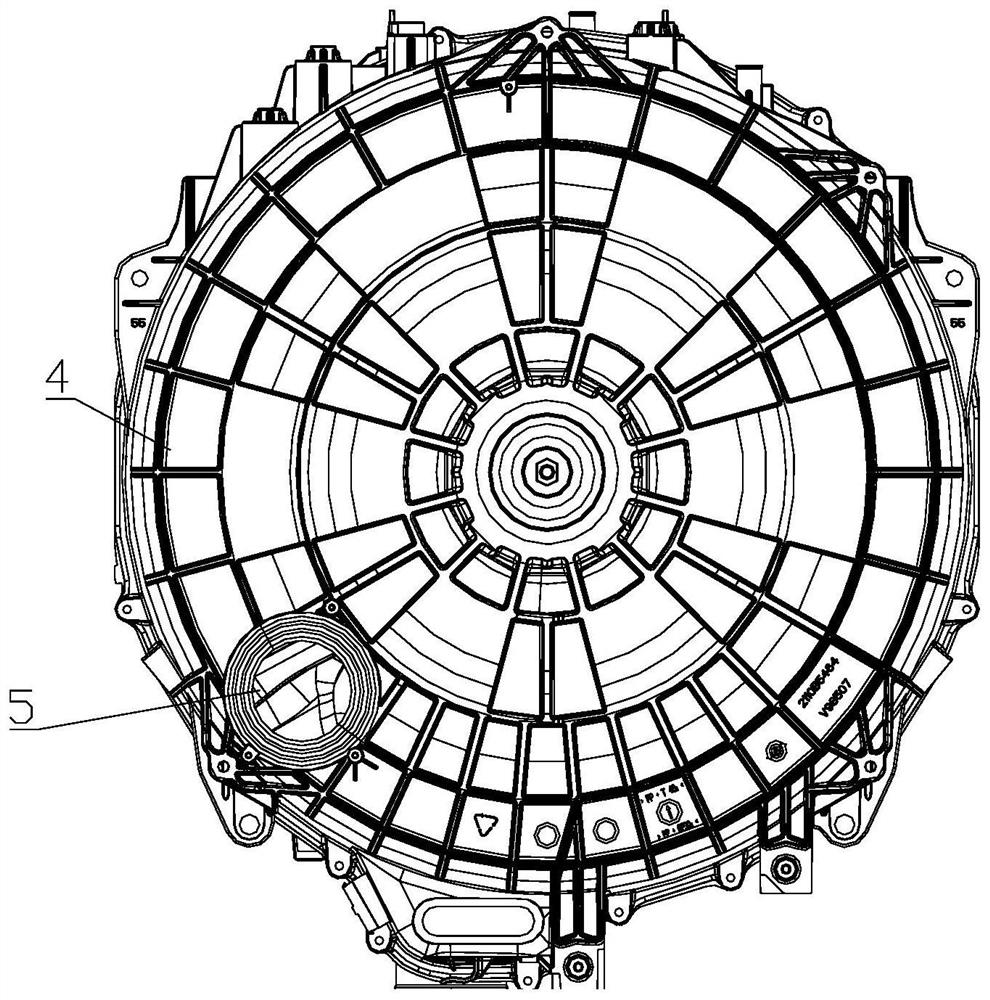

[0041] Such as Figure 1 to Figure 3 As shown, the sealing structure of this embodiment includes a support member and a seal member that can be sealed or separated, the support member is fixed at the rear of the outer cylinder 2 / the rear of the inner cylinder 1, and the seal is fixed at the rear of the inner cylinder 1 / Corresponding position at the rear of the outer cylinder 2.

[0042] In this embodiment, the sealing structure includes two parts that cooperate with each other, that is, the supporting part and the sealing part. The setting positions of the supporting member and the sealing member cooperate with each other and correspond to each other. When the support is fixed at the rear of the outer cylinder 2, the seal is fixed at the corresponding position of the inner cylinder 1 rear; when the support is fixed at the rear of the inner cylinder 1, the seal is fixed at the corresponding position of the outer cylinder 2 rear. In this way, under different circumstances, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com