Joint connecting structure of profile steel-UHPC composite board

A technology of combining slabs and section steels, applied in bridge parts, erecting/assembling bridges, bridge materials, etc., can solve problems such as difficulty in applying large-span bridges, increasing average slab thickness, and large pouring volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

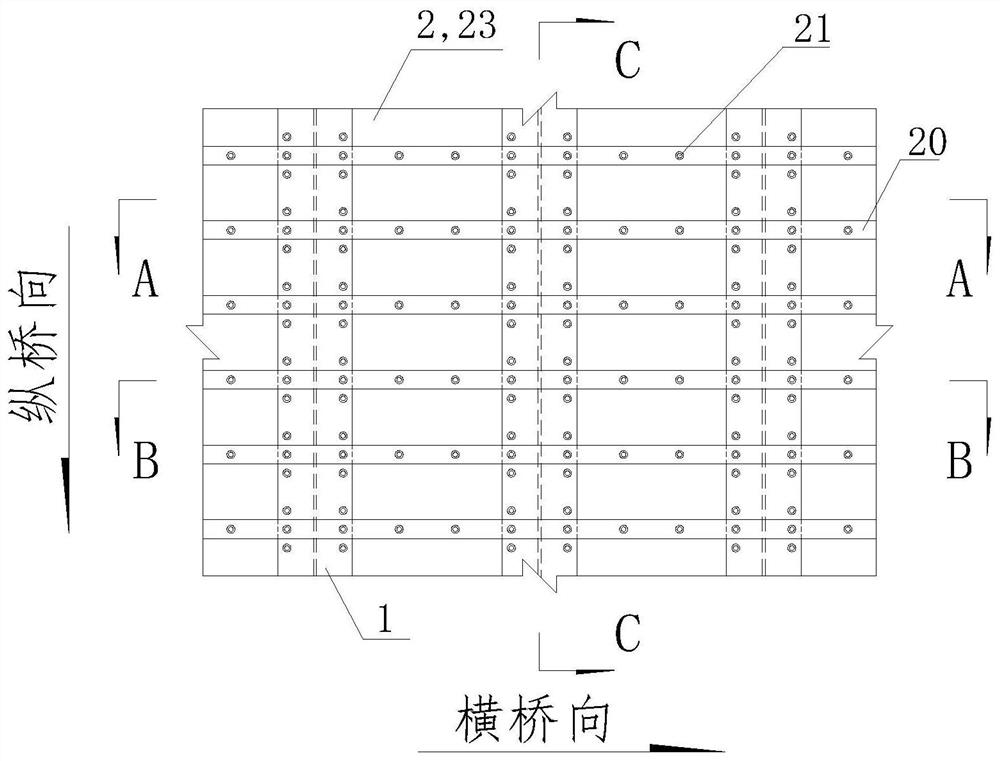

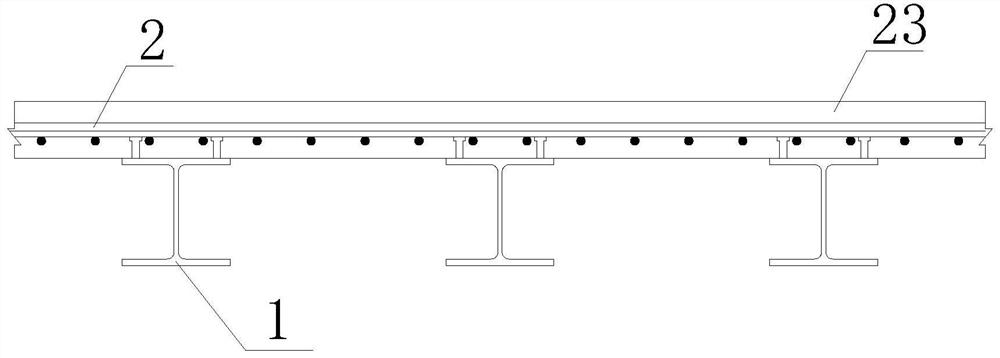

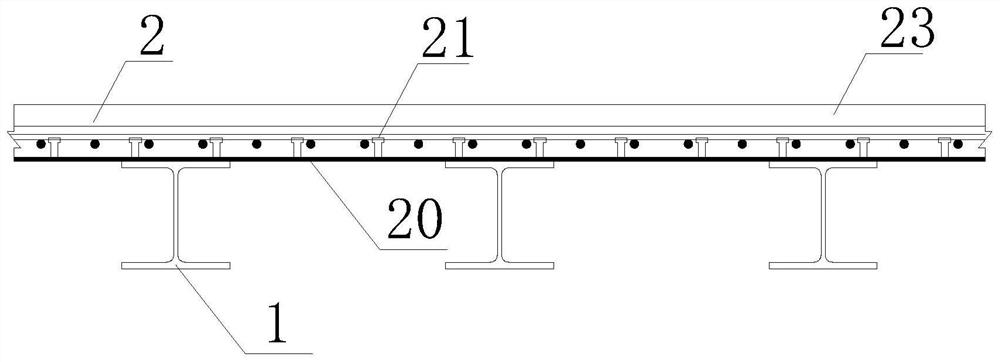

[0075] Such as Figure 1-4 with Figure 17-24 As shown, the joint connection structure of the steel-UHPC composite panel in this embodiment, the steel-UHPC composite panel includes a plurality of steel sections 1 and UHPC panels 2 affixed to the section steel 1, and a plurality of shear connections are welded in the section steel 1 A piece 21 (such as a peg) is used for connecting the UHPC board 2 . The seam connection structure includes the steel-UHPC composite plates adjacent to the longitudinal bridge and the transverse joint structure between the steel-UHPC composite plates adjacent to the longitudinal bridge. The transverse cast-in-place UHPC connection part 3 between 2 and the fixed connecting piece used to connect the adjacent section steel 1, the transverse joint structure and the center distance k between the transverse diaphragm 4 or the transverse beam closest to it is the The center-to-center distance between the plates 4 or the center-to-center distance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com