Automatic ball delivering device used for perforating and fracturing continuous operation

A ball-throwing device and driving device technology, applied in the direction of wellbore/well valve device, production fluid, wellbore/well components, etc., can solve the problems of low ball-throwing efficiency and poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

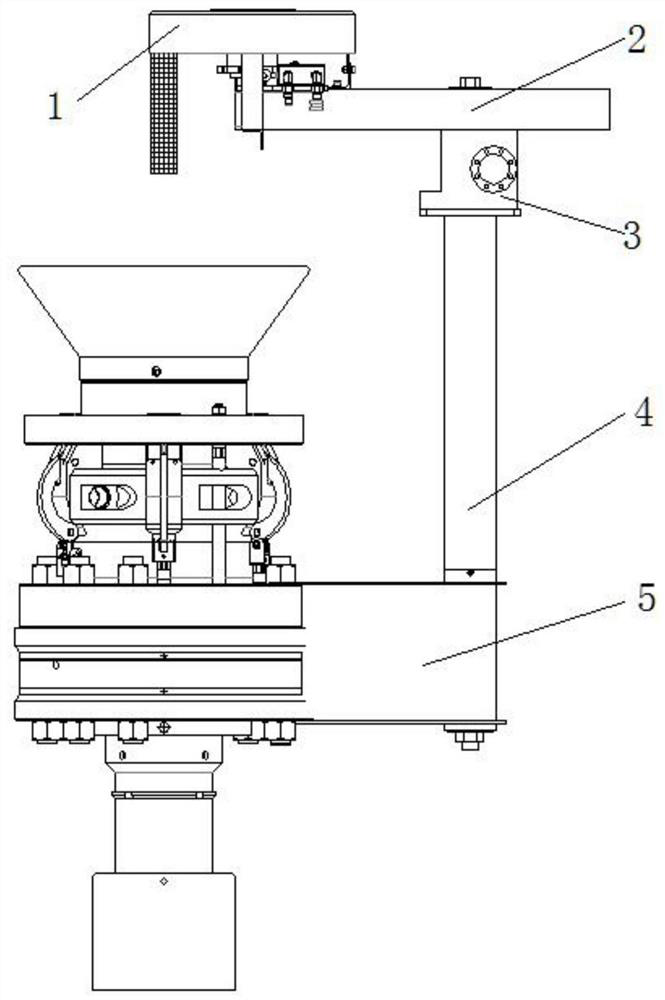

[0022] Such as Figure 1-4 As shown, an automatic ball-throwing device for continuous operation of perforation and fracturing, including a ball-throwing assembly 1, a frame body 2, a rotating device 3 and a pole 4, the ball-throwing assembly 1 is arranged at one end of the frame body 2, and the The other end of the frame body 2 is connected to the pole 4 through the rotating device 3, and the rotating device 3 is specifically configured as a swing oil cylinder. When the ball is not needed, the ball throwing assembly 1 can be rotated to other positions so that For the installation and use of related equipment;

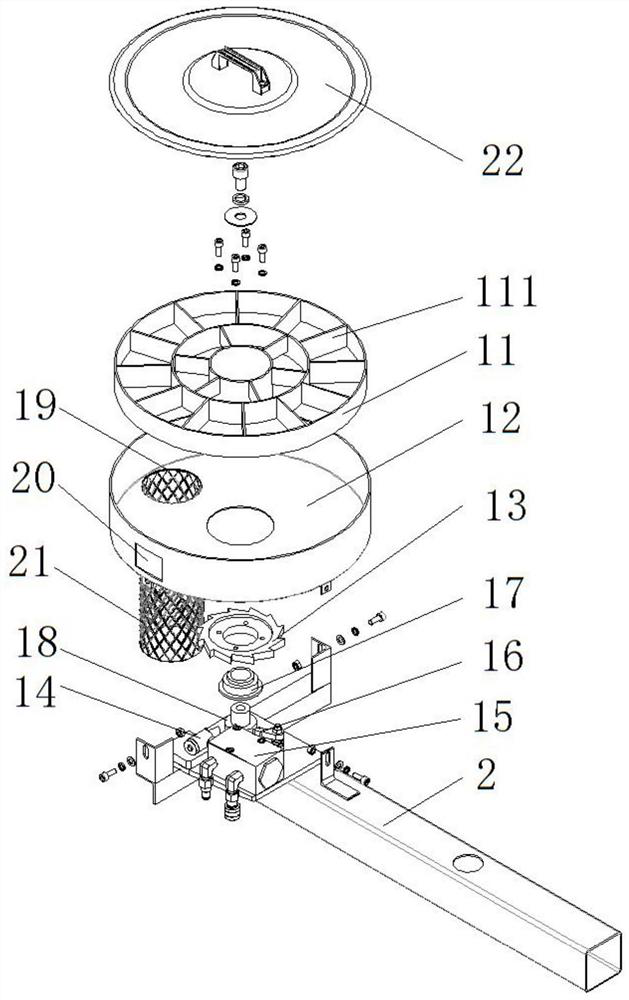

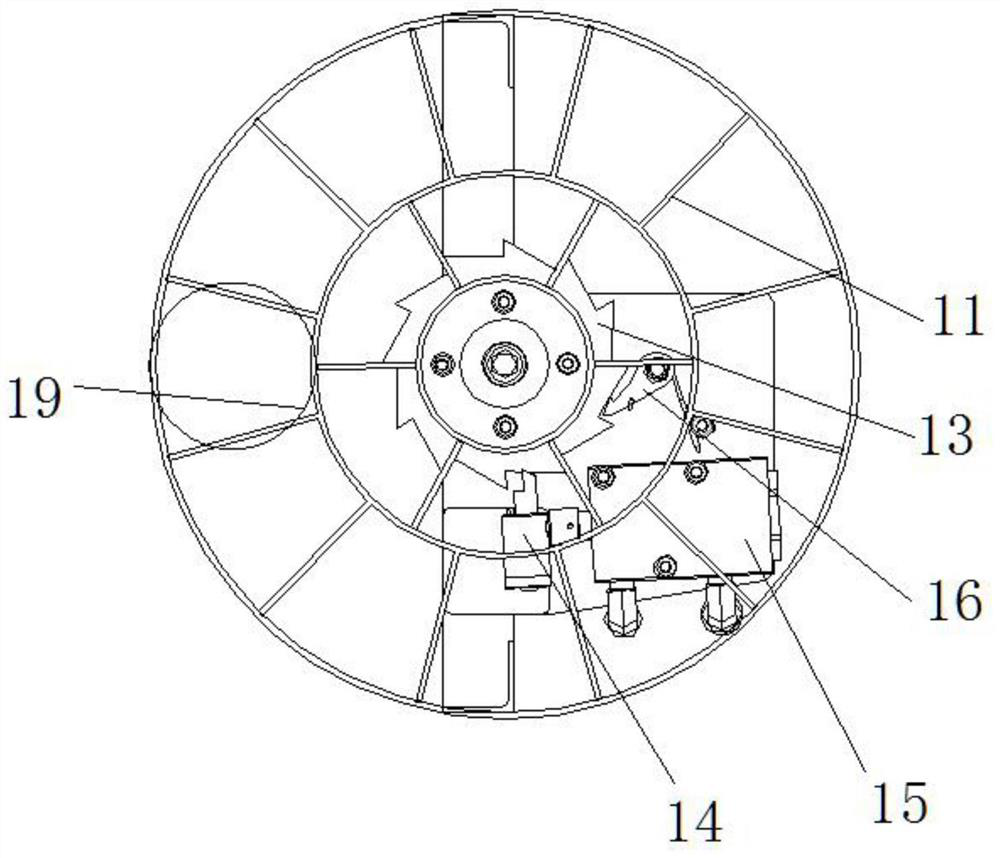

[0023] Such as figure 2 with 3 As shown, the ball throwing assembly 1 includes a ball spacer drum 11, a drum guard 12, a ratchet 13, a needle 14, a driving device 15 and a non-return pawl 16, and the drum guard 12 is fixed on the frame On the body 2, the drum shield 12 is provided with a shield cover 22, the ball-separating drum 11 is arranged in the inner cavity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com