Underground extraction outburst elimination device and operation method thereof

A technology for extraction and outburst elimination, applied in the field of outburst elimination in coal mines, can solve the problems of airflow blockage, high risk, and difficulty in sealing down holes through layers, so as to reduce interference and improve collection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

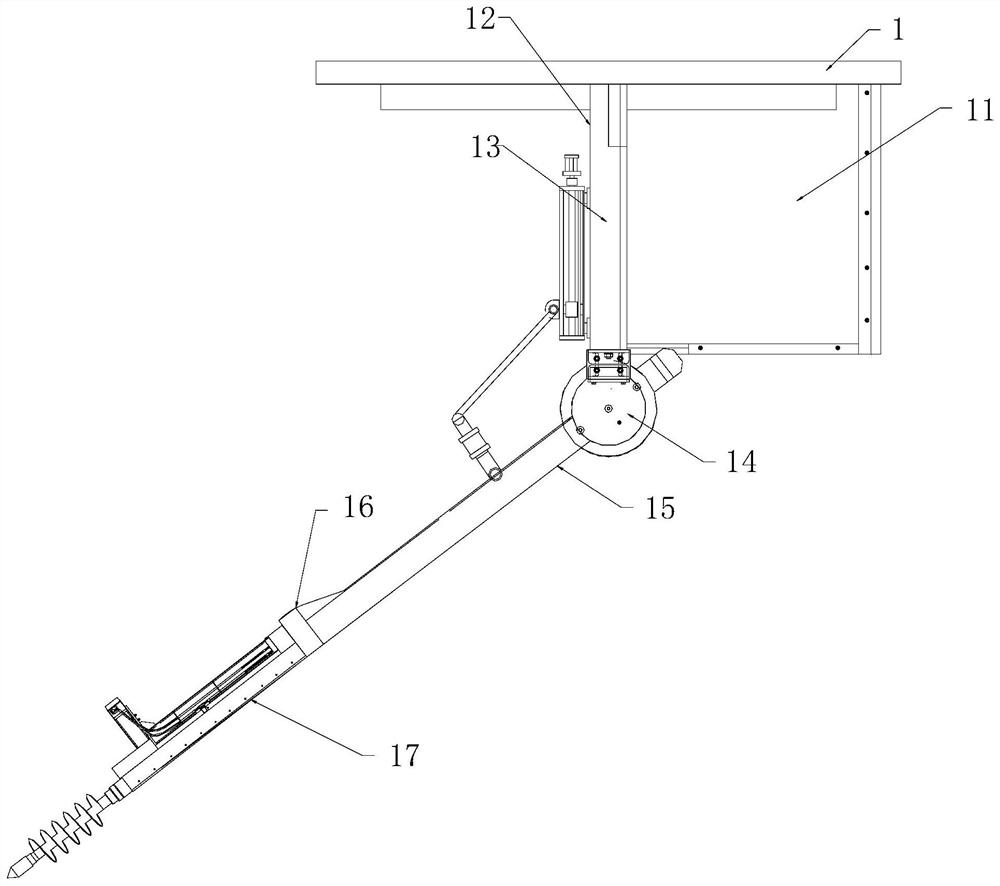

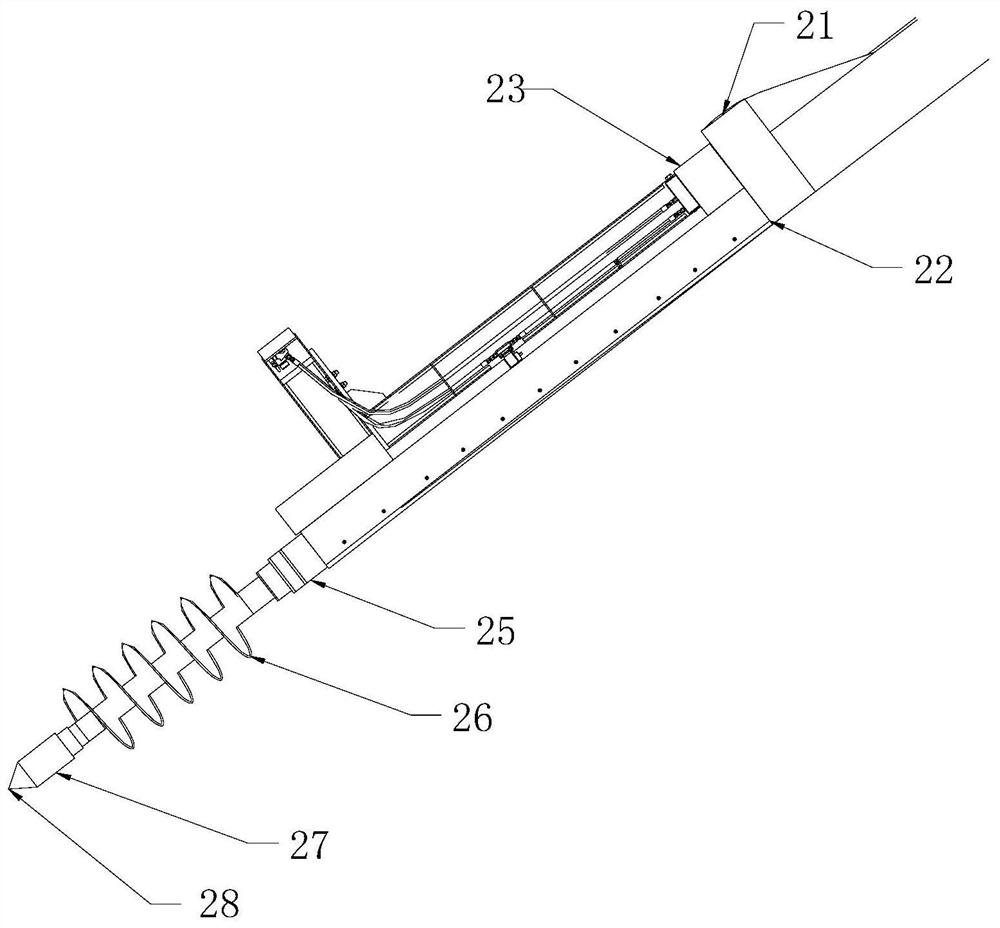

[0036] see figure 1 , a mining outburst elimination device under mine, comprising a frame 1, a processing box 11 is arranged on the frame 1, a foundation support 12 is installed on the front side of the treatment box 11, and a foundation support 12 is installed on the foundation support 12 A main bracket 13 is installed, the bottom end of the main bracket 13 is provided with a steering wheel 14, and an operation frame 15 is installed on the steering wheel 14, and the bottom end of the operation frame 15 is installed with a pumping device through a locking installation sleeve 16. Mechanism 17; the processing compartment 11 is used for temporary storage and processing of the extracted phase materials, the foundation support 12 is an overall installation device on the foundation, the main support 13 is a vertical support mechanism, and the steering wheel 14 drives the work frame 15 Rotate to adjust the operating angle, and the extraction mechanism 17 is used for extraction operat...

Embodiment 2

[0044] see figure 1 and Figure 6 , this embodiment is a further optimization of the first embodiment, on the basis of which, the bottom end of the main bracket 13 is equipped with a clamping seat 69, and the steering wheel 14 is installed between the clamping seats 69 through a support shaft, so The side of the main support 13 is also equipped with a transmission frame 61, the side of the transmission frame 61 is provided with a sliding track 62, the sliding track 62 is equipped with a displacement seat 63, and the external connection of the displacement seat 63 is installed with an adjustment support. Rod 64, the bottom end of the adjustment pole 64 is installed and fixed with the work frame 15 through the lower installation frame 65. The inner cavity of the transmission frame 61 is provided with a transmission screw rod 67 , and a built-in screw sleeve 66 is installed on the transmission screw rod 67 , and the built-in screw sleeve 66 is connected with the displacement sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com