Variable-flow-channel waterproof hammer air valve and design method

A technology of air valve and variable flow channel, which is applied in the direction of valve details, control valves, valve devices, etc., and can solve problems such as uneven force on the throttle ring, land acquisition, troublesome operation and maintenance, high equipment cost, and high installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

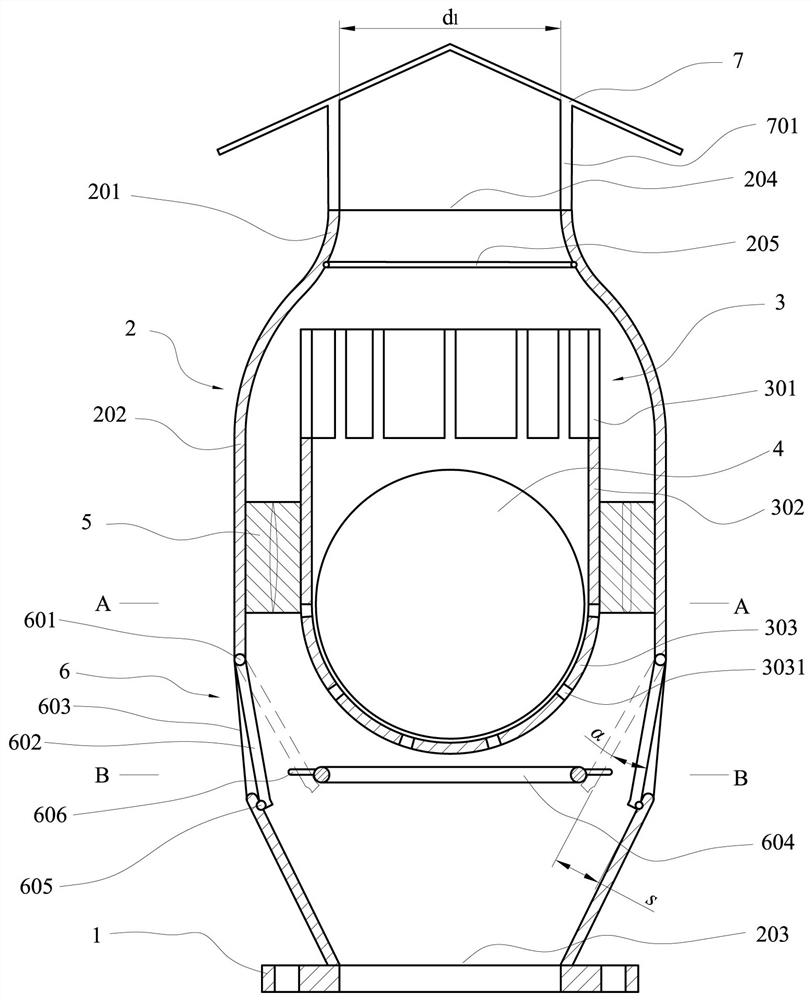

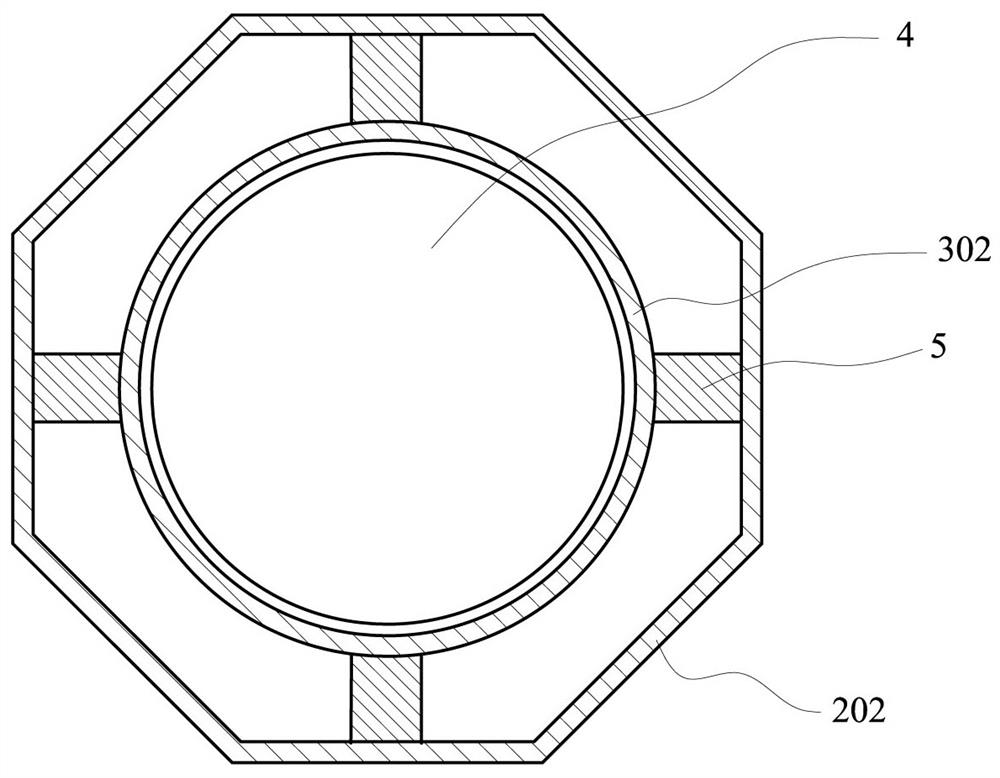

[0062] This embodiment is a variable channel anti-hammer air valve, such as figure 1 mentioned. This embodiment includes a valve body 2 with a connecting piece 1 at the bottom that can be connected to a water pipeline. The cross-sectional shape of the middle raised portion 202 is a regular polygon, such as figure 2 as shown ( figure 2 Shown in is a regular octahedron, that is, a valve body with a regular octagonal cross-section), the bottom of the valve body is provided with a fluid inlet and outlet 203, and the top is provided with an inlet and outlet 204, and the inlet and outlet are provided with a seal Ring 205, below the intake and exhaust ports are the ball valve seat 3 and the floating ball 4, and the ball valve seat from top to bottom is a grid 301, a guide sleeve 302 and a floating ball base with a plurality of flow holes 3031 303, the ball valve seat and the valve body are fixedly connected through the guide sleeve bracket 5, and the lower half of the middle rai...

Embodiment 2

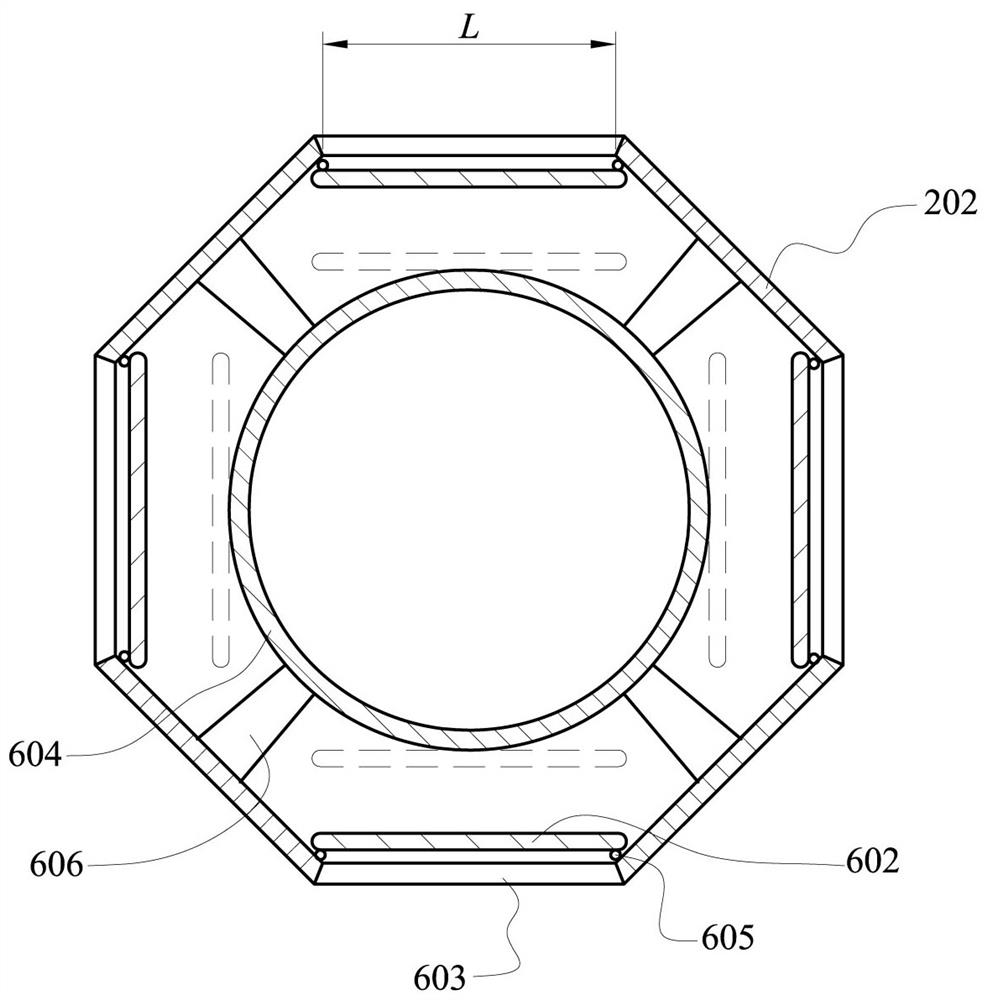

[0071] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment on the facilities for limiting the opening of the valve clack. The facility for limiting the opening of the disc described in this embodiment is a limit ring, and the limit ring is fixedly connected with the valve body through a limit ring bracket, see figure 1 and image 3 , the dotted line in the figure indicates the position of the swing valve clack when it is opened.

[0072] In this embodiment, the position of the limit ring is such that the edge of the ring can block the swing-type valve disc to continue to open. The limit ring can be circular, or a regular polygon that matches the valve body, such as the valve body is a regular octahedron , the limit ring is a regular octagon.

Embodiment 3

[0074] This embodiment is an improvement of the above embodiment, and is a refinement of the above embodiment regarding the swing opening and closing angle of the swing valve clack. The swing-type disc swing opening and closing angle α of the swing-type check valve described in this embodiment is 30-45°, such as figure 1 shown.

[0075] The opening and closing angle should not be too large. If it is too large, it will be easily impacted by the water flow and cannot be closed. If it is too small, it will not be conducive to the flow of air. The choice of α angle should be determined according to the air flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com