Vehicle ambient lighting

An ambient light and vehicle technology, applied in the field of vehicle interior parts, can solve the problems of limited lighting extension, long time consumption, easy to decrease sealing performance, etc., to avoid hidden dangers of water leakage, good waterproof and dustproof function, and save sealant. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

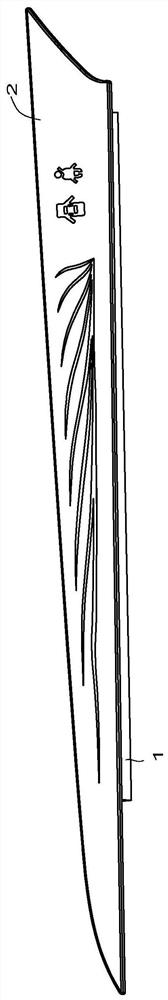

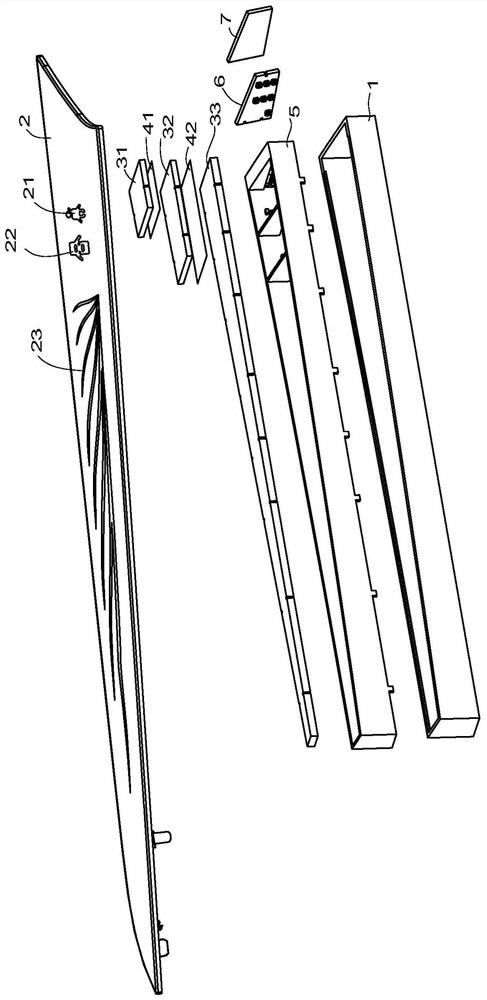

[0030] Such as figure 1 , figure 2 As shown, the vehicle atmosphere lamp in this embodiment includes a housing 1, a bracket 5, a first light guide plate 31, a first light shielding film 41, a second light guide plate 32, a second light shielding film 42, a third light guide plate 33, a PCB Plate 6 and shading plate 2.

[0031] The upper end of the casing 1 is opened to form a port; the bracket 5 is arranged in the casing 1 and has an internal cavity; the first light guide plate 31 is arranged in the inner cavity of the bracket 5; the first light shielding film 41 is arranged on the back of the first light guide plate 31 .

[0032] The second light guide plate 32 is arranged in the inner cavity of the bracket 5, and is positioned below the first light guide plate 31; Below the second light guide plate 32 .

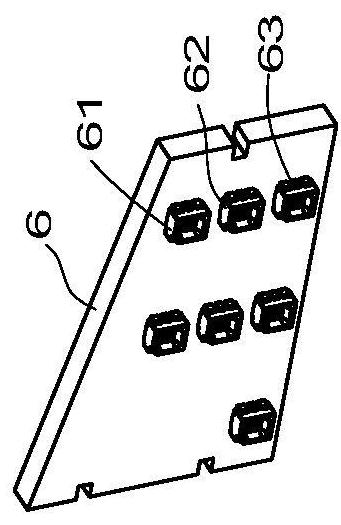

[0033] combine image 3 As sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap