Secondary light concentrating reflection-uniform heat flow trough type solar heat collector

A trough-type solar energy and secondary concentrating technology, which is applied to solar collectors, solar collectors using working fluids, solar thermal energy, etc., can solve the problem of uneven distribution of heat flux density in the circumferential direction of the collector tube and affect the heat collector Heat collection efficiency, heat collection tube mechanical damage and other issues, to achieve the effect of solving thermal stress damage, improving heat collection efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, without limiting the invention.

[0025] A specific example of the design will be described below.

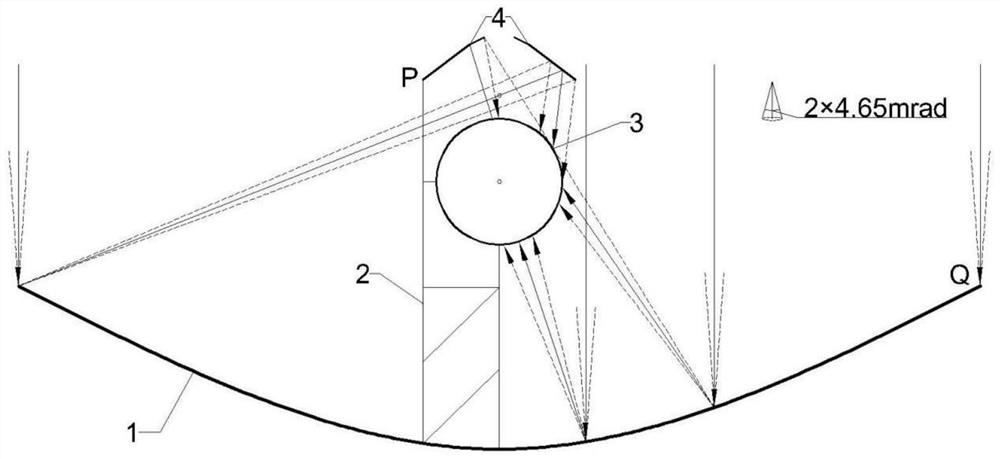

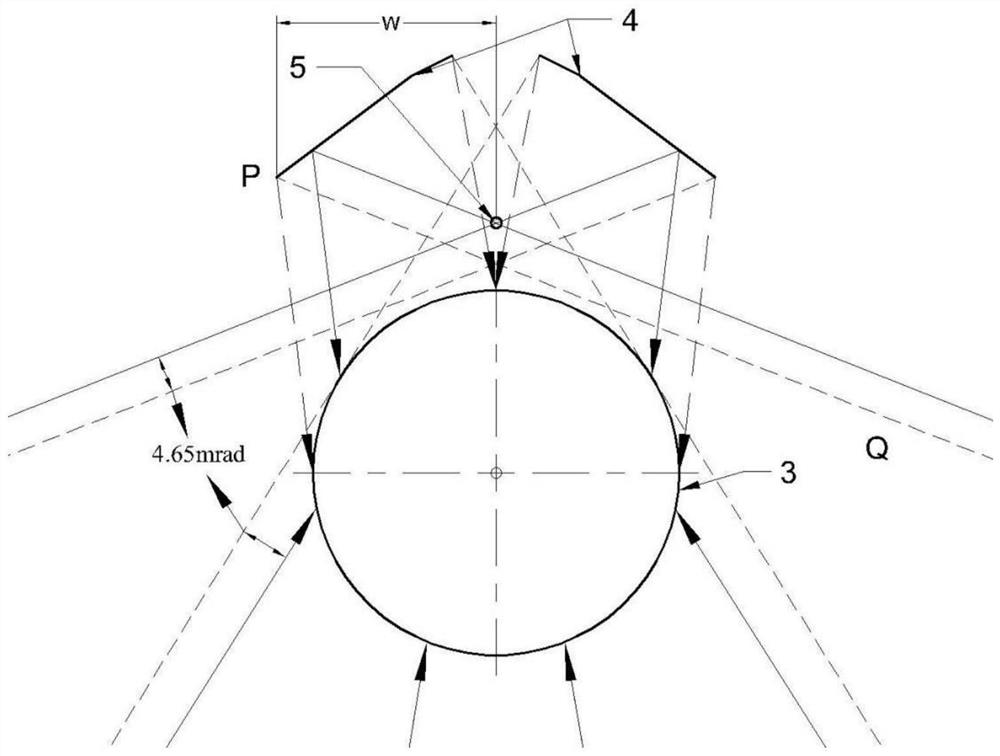

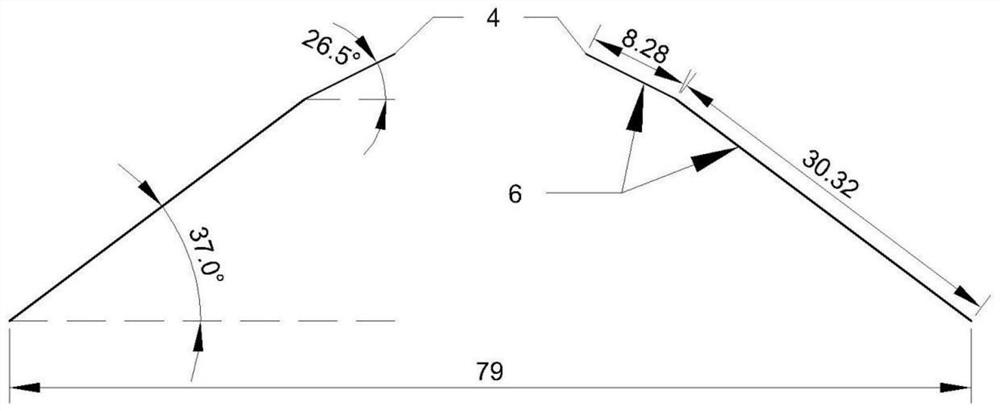

[0026] Such as figure 1 As shown, the secondary concentrating reflection-uniform heat flow trough solar collector provided by the present invention includes a parabolic trough reflector 1, a reflector support 2, a vacuum heat collecting tube 3 and a secondary composite plane reflector 4, and the vacuum collector The heat pipe 3 and the secondary composite plane reflector 4 are erected on the reflector bracket 2 . The length of the parabolic trough reflector unit is 4m, 6m or 7.8m, the opening width is 5m, the focal length is 1.84m; the outer diameter of the vacuum heat collecting tube is 70mm. The sunlight is actually a cone-shaped light. When the half-vertex angle of the sunlight cone is 4.65mrad, a small part of the approximately parallel sunlight is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com