Modified plastic pellet drying system

A drying system and dicing technology, which is used in the drying of granular materials, drying solid materials, and drying goods processing, etc., can solve the problems of unreachable and unsolved modified plastic pelletizing and drying, and can not achieve energy saving, etc. achieve the effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

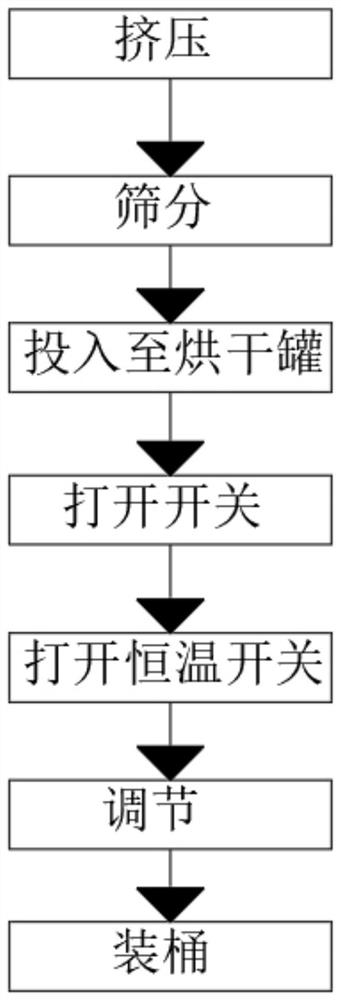

[0026] A modified plastic cutting and drying system includes the following steps:

[0027] S1. Extrusion: put the modified plastic pellets to be dried into the inside of the tank, and carry out the extrusion work, and the extrusion time is 1min;

[0028] S2. Screening: introduce the modified plastic pellets extruded in S1 above into the screening device for screening, and remove the small pellets that do not meet the specifications in the modified plastic pellets. The sub-time is 5 minutes;

[0029] S3. Putting it into the drying tank: introduce the modified plastic pellets screened in S2 above into the drying tank, and the modified plastic pellets will fall on the upper surface of the mesh belt inside the drying tank for drying. , the drying time is 20min;

[0030] S4. Open the switch: connect the power supply device, open the steam valve, open the front and rear moisture discharge switches, open the motor, and make the motor work to drive the mesh belt to shake;

[0031] ...

Embodiment 2

[0042] A modified plastic pelletizing drying system is characterized in that it includes the following steps:

[0043] S1. Extrusion: put the modified plastic pellets to be dried into the inside of the tank, and carry out the extrusion work, and the extrusion time is 1.5min;

[0044] S2. Screening: introduce the modified plastic pellets extruded in S1 above into the screening device for screening, and remove the small pellets that do not meet the specifications in the modified plastic pellets. The sub-time is 7.5 minutes;

[0045] S3. Putting it into the drying tank: introduce the modified plastic pellets screened in S2 above into the drying tank, and the modified plastic pellets will fall on the upper surface of the mesh belt inside the drying tank for drying. , the drying time is 25min;

[0046] S4. Open the switch: connect the power supply device, open the steam valve, open the front and rear moisture discharge switches, open the motor, and make the motor work to drive th...

Embodiment 3

[0058] A modified plastic pelletizing drying system is characterized in that it includes the following steps:

[0059] S1. Extrusion: put the modified plastic pellets to be dried into the inside of the tank, and carry out the extrusion work. The extrusion time is 2 minutes;

[0060] S2. Screening: introduce the modified plastic pellets extruded in S1 above into the screening device for screening, and remove the small pellets that do not meet the specifications in the modified plastic pellets. The sub-time is 10 minutes;

[0061] S3. Putting it into the drying tank: introduce the modified plastic pellets screened in S2 above into the drying tank, and the modified plastic pellets will fall on the upper surface of the mesh belt inside the drying tank for drying. , the drying time is 30min;

[0062] S4. Open the switch: connect the power supply device, open the steam valve, open the front and rear moisture discharge switches, open the motor, and make the motor work to drive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com