Method for quickly and qualitatively detecting whether packing material contains copper or not

A qualitative detection and packaging technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, can solve the problems of low control rate of copper ions, damage to packaging, and waste of sample delivery. In order to achieve the effect of simple and easy-to-operate analysis methods, reduce damage, save manpower and detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

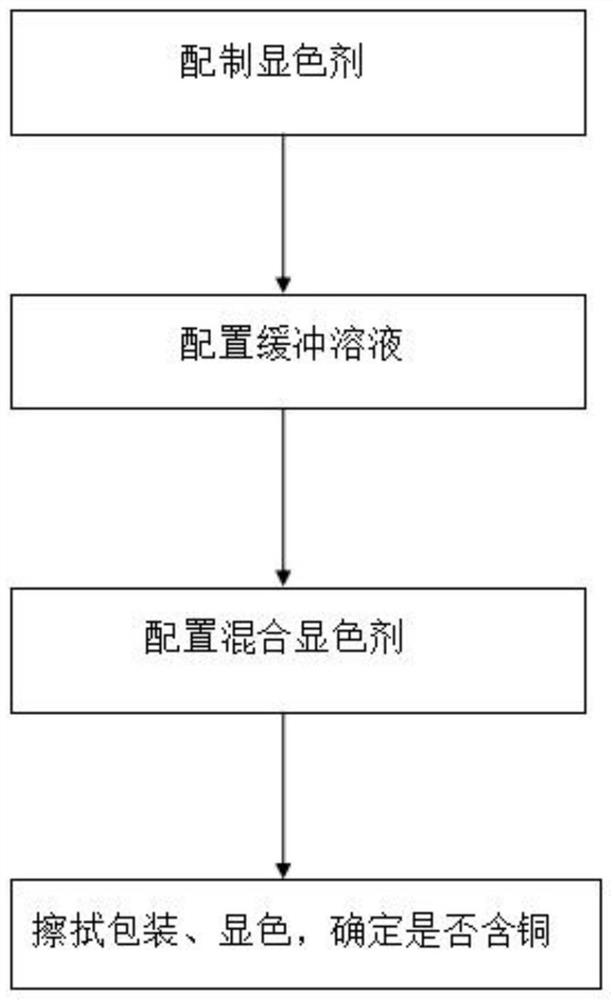

[0019] A rapid qualitative detection method for whether copper is contained in a package is characterized in that:

[0020] The first step: configure the color developing solution, by accurately weighing 0.4000 g of dicyclohexanone oxalyl bishydrazone, dissolving it in 150 mL of absolute ethanol, stirring and dissolving in a constant temperature water bath at 60°C, and cooling to form a color developing solution. Transfer the color developing solution into a 200mL volumetric flask, add absolute ethanol to make the volume up to the 200mL scale line;

[0021] Step 2: Configure the buffer solution. Dissolve 60.00g of ammonium acetate and 10.00g of sodium acetate in 150mL of hot water by accurately weighing, stir to dissolve, and cool to form a buffer solution. Transfer the buffer solution into a 200mL volumetric flask and add Constant volume of resin water to 200mL scale line;

[0022] The third step: mix the color developing solution and the buffer solution in a volume ratio of 1:1 to...

Embodiment 2

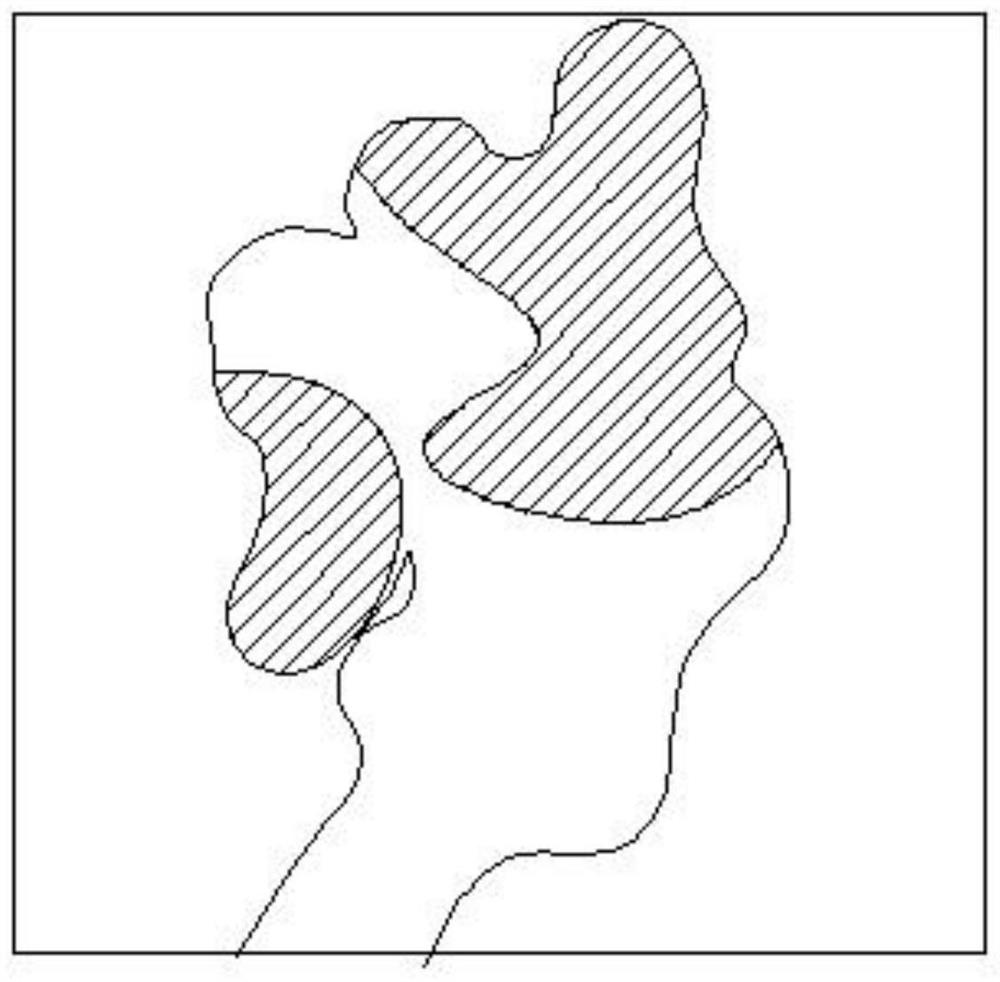

[0026] The present invention first sets a blank control: drip 3 to 4 drops of the mixed reagent on a clean dust-free cloth. After 20 seconds, the area to be dripped can be used as a blank control, such as figure 2 As shown; compared with the blank control, after vigorously wiping the test object with a dust-free cloth, drop 3 to 4 drops of the mixed reagent on the dust-free cloth and wipe the part vigorously. If the dust-free cloth wipes the part strongly within 20 seconds, blue Color, it means the surface of the tested part contains copper, such as image 3 As shown; if there is no blue appearance on the part when the dust-free cloth is wiped strongly within 20 seconds, it means that the surface of the tested part does not contain copper; if the individual points on the part where the dust-free cloth is wiped strongly within 20 seconds, slight blue spots appear, It means that there is slight copper pollution on the surface of the tested part, such as Figure 4 Shown

[0027] Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap