Anti-torsion solid-core polarization-maintaining photonic crystal fiber based on stress distribution anisotropy

A photonic crystal fiber, anisotropic technology, applied in the direction of polarization fiber, cladding fiber, microstructure fiber, etc., can solve the problems of hindering the fiber optic gyroscope, increasing the cost of preparation, increasing the volume and quality of the fiber optic gyroscope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

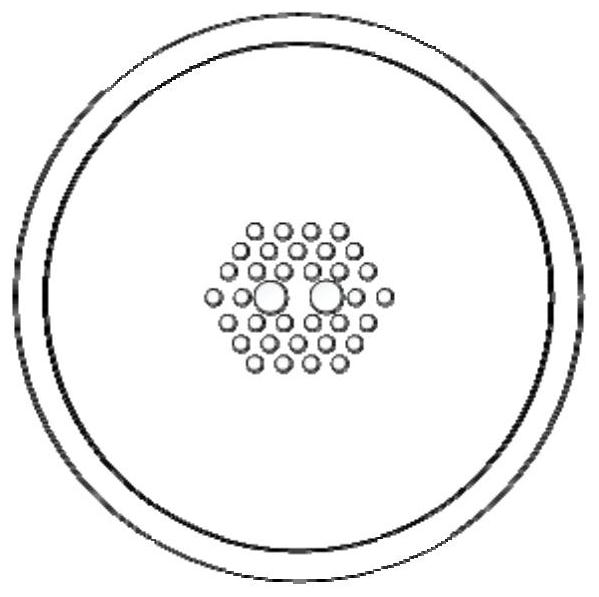

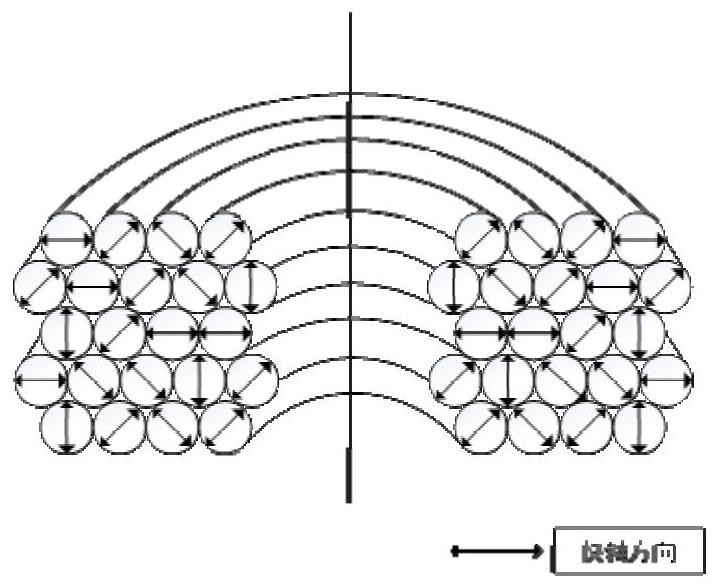

[0036] Such as Figure 4 As shown, the cladding inner region S of the photonic crystal fiber based on the stress distribution anisotropy of embodiment 1 内 It is a three-layer periodic and evenly distributed air hole area arranged around the fiber core, and the outer layer area S 外 is the area between the inner zone and the cladding wall. where the inner region S 内 The inner layer structure uses two larger micron-sized air holes on the x-axis to form shape birefringence. Preferably, the diameter of the micron-sized air holes is 4-6 μm, and the outer region S 外 The outer structure of is mainly distributed on the y-axis, where the x-axis points to the horizontal direction and the y-axis points to the vertical direction. Considering the feasibility of stacking capillaries in the preparation process, the air holes in the outer area are arranged in a honeycomb structure, and the inner area S 内 and the outer region S 外 The overall structure is symmetrical about both the x-axis a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com