A kind of three-dimensional coating in-mold labeling and in-mold labeling method

A covering mold and three-dimensional technology, which is applied in the field of three-dimensional covering in-mold labeling and in-mold labeling, can solve the problems of added value, monotony, layering, three-dimensional texture and poor touch of difficult products, and achieve Improve market efficiency, reduce production costs, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

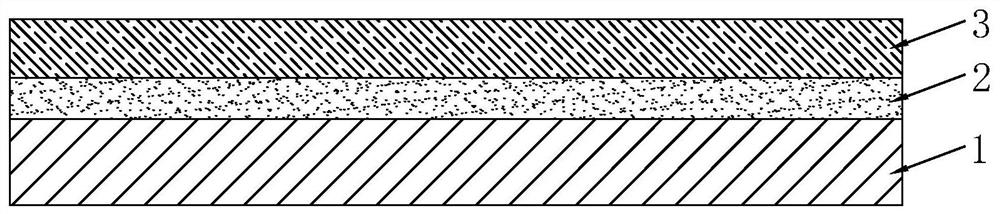

[0049] A three-dimensional overmold in-mold label, see figure 1 , including a base film layer 1, an adhesive layer 2, and a decorative film layer 3. Wherein, the base film layer 1 can be pasted on a specified attachment, such as a plastic container or component.

[0050] The base film layer 1 is preferably modified PP film or ABS film. Its thickness is preferably controlled between 0.05mm-0.2mm.

[0051] Decorative film layer 3 preferably adopts BOPP film or APET film. Its thickness is preferably controlled between 0.035mm-0.1mm.

[0052] The decorative film layer 3 is adhered to the base film layer 1 by uniformly coating the adhesive layer 2 formed by specific watering, thereby forming a complete composite label.

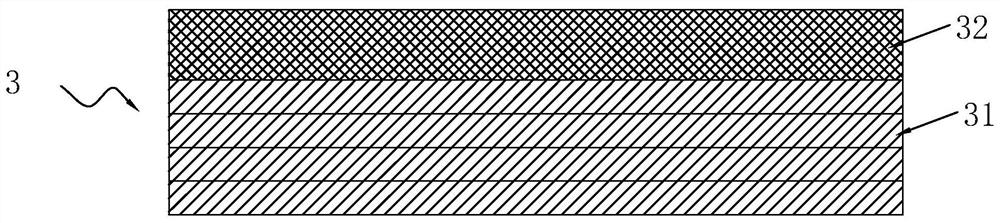

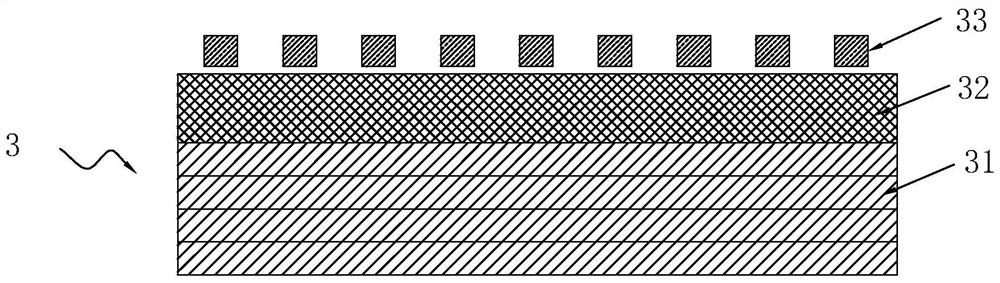

[0053] see figure 1 , figure 2 as well as image 3 The decorative film layer 3 includes a printing image ink layer 31, a decorative film transparent base layer 32, and a textured touch layer 33. The printed image ink layer 31, the decorative film transparent ...

Embodiment 2

[0056] On the basis of Embodiment 1, the following structures are added.

[0057] see Figure 4 , a vacuum coating layer 4 is also provided, and the vacuum coating layer 4 is located between the textured touch layer 33 and the printed image ink layer 31 . The transparent base layer 32 of the decorative film is located on the side of the textured touch layer 33 away from the vacuum coating layer 4 . The combination of vacuum coating decoration technology and 3D ultra-fine texture transfer can produce colorful in-mold labeling effects.

Embodiment 3

[0059] The following structure is added on the basis of the second embodiment.

[0060] see Figure 5 , is also provided with a metal film layer 5, the adhesive layer 2 is provided with two layers, the metal film layer 5 is located between the decorative film layer 3 and the base film layer 1, and the two adhesive layers 2 are respectively located between the decorative film layer 3 and the metal film layer 5 between the metal film layer 5 and the base film layer 1 .

[0061] The metal film layer 5 is an aluminum film layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com