Winding machine and method for full-automatic take-up and pay-off

A technology of winding and unwinding machines, applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc., which can solve problems such as error-prone, low product production efficiency, and single production line, so as to avoid breakage and improve winding The effect of high line quality and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

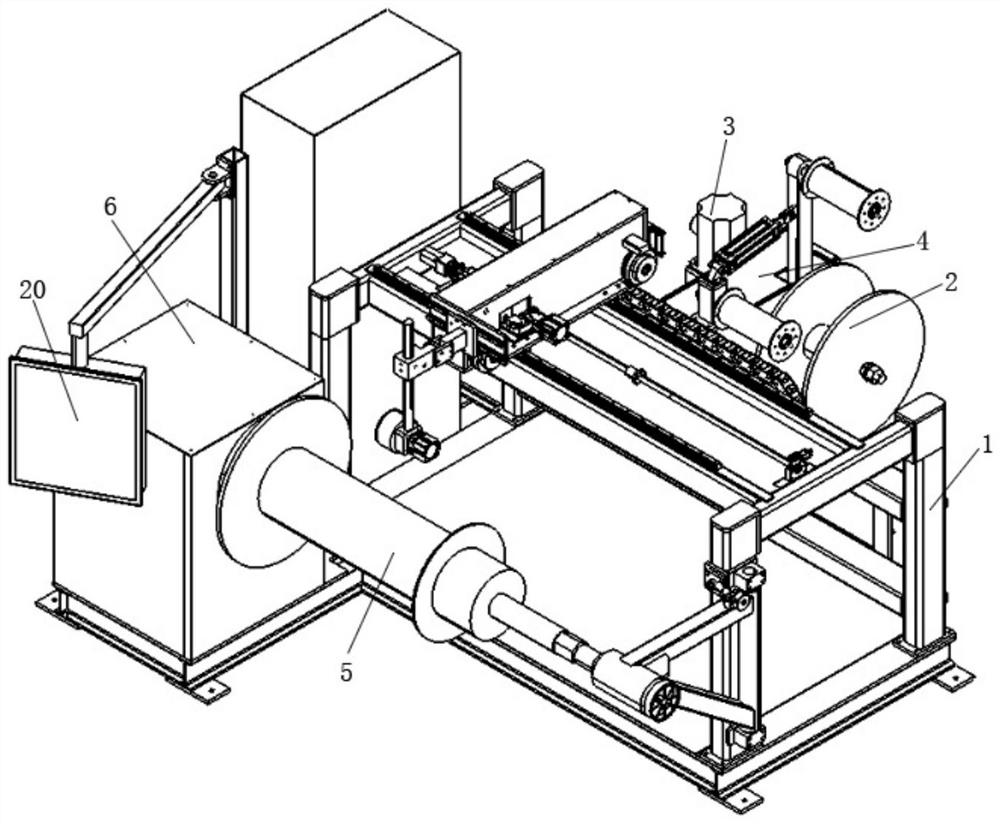

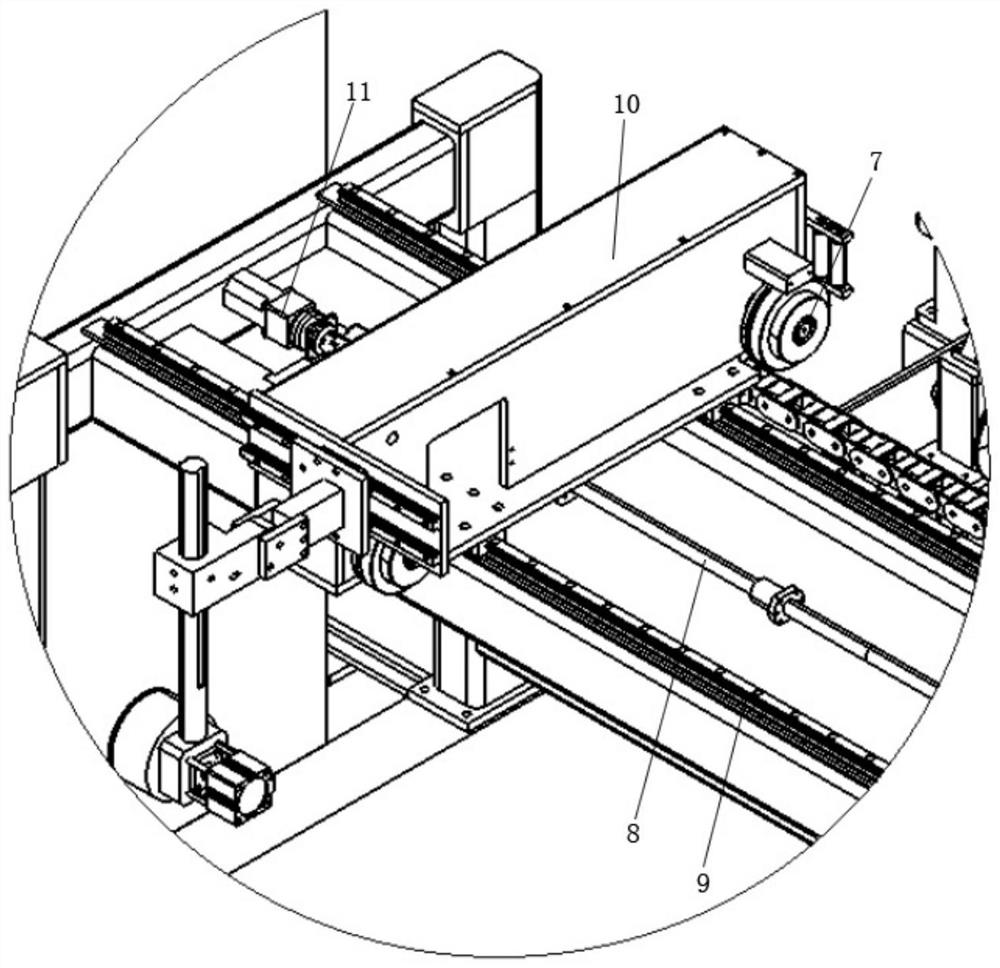

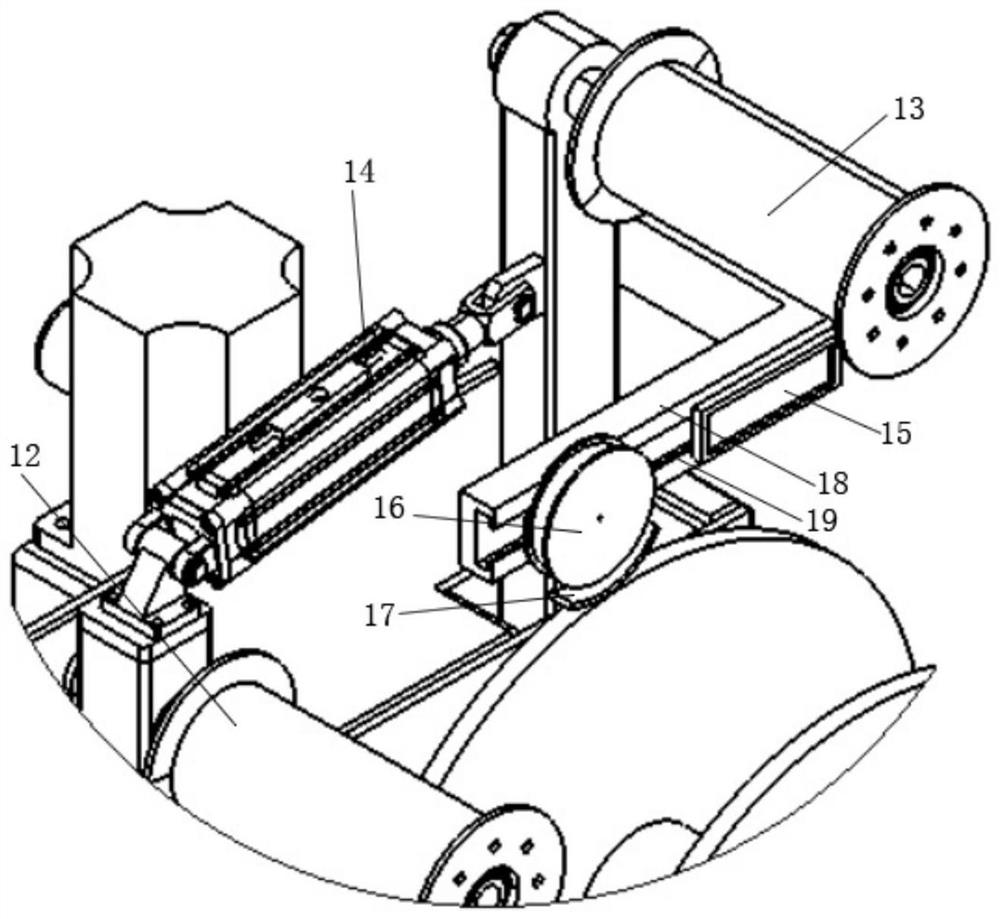

[0022] Such as figure 1 As shown, a fully automatic wire winding machine includes a base 1, a wire releasing device, a wire arranging device, a winding device and a control system. On the left and right sides, the cable arrangement device includes a main cable arrangement mechanism and an auxiliary cable arrangement mechanism. The system is respectively connected with the pay-off device, the cable arrangement device and the winding device to control the precise winding.

[0023] The pay-off device includes a pay-off cylinder 2, a pay-off motor 3 and a pay-off translation mechanism, and the pay-off translation mechanism includes a pay-off translation screw, a pay-off translation slide rail, a pay-off translation slider 4 and a pay-off translation motor arranged in parallel. , the pay-off translation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com