Transformer winding device

A technology of winding device and transformer, which is applied in inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problems of wasting the internal space of the transformer, affecting the quality of the transformer, and the winding of the transformer is not tight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

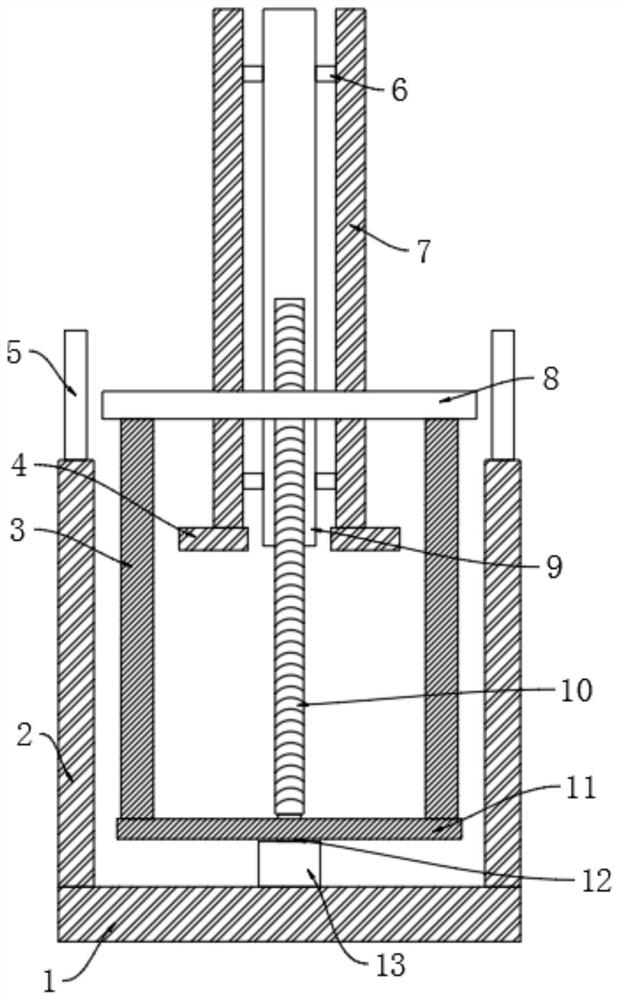

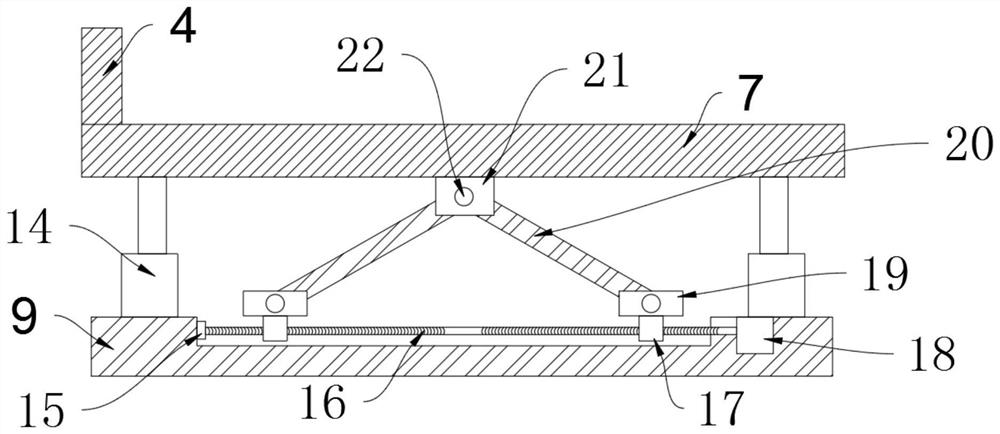

[0020] see Figure 1-4 , a transformer winding device, including a base 1, a side support rod 2 and a winding structure, the side support rod 2 is fixed on the side of the base 1, a winding structure is fixed above the base 1, and the winding structure The wire structure includes a bottom motor 13, a rotating shaft 12, a fixed turntable 11, a screw rod 10, a fixed seat 3, a winding mechanism, a built-in threaded sleeve 9, a clamping plate 7 and a support structure 6, and a bottom is fixed at the middle position above the base 1. Motor 13, the bottom motor 13 drives and connects the rotating shaft 12, the middle of the rotating shaft 12 is fixed with a fixed turntable 11, the rotating shaft 12 passes through the fixed turntable 11 and the end of the rotating shaft 12 is fixed with a screw 10, the screw 10 is threadedly connected to the built-in threaded sleeve 9, the built-in threaded sleeve 9 is externally fixed with a support structure 6, the end of the support structure 6 is...

Embodiment 2

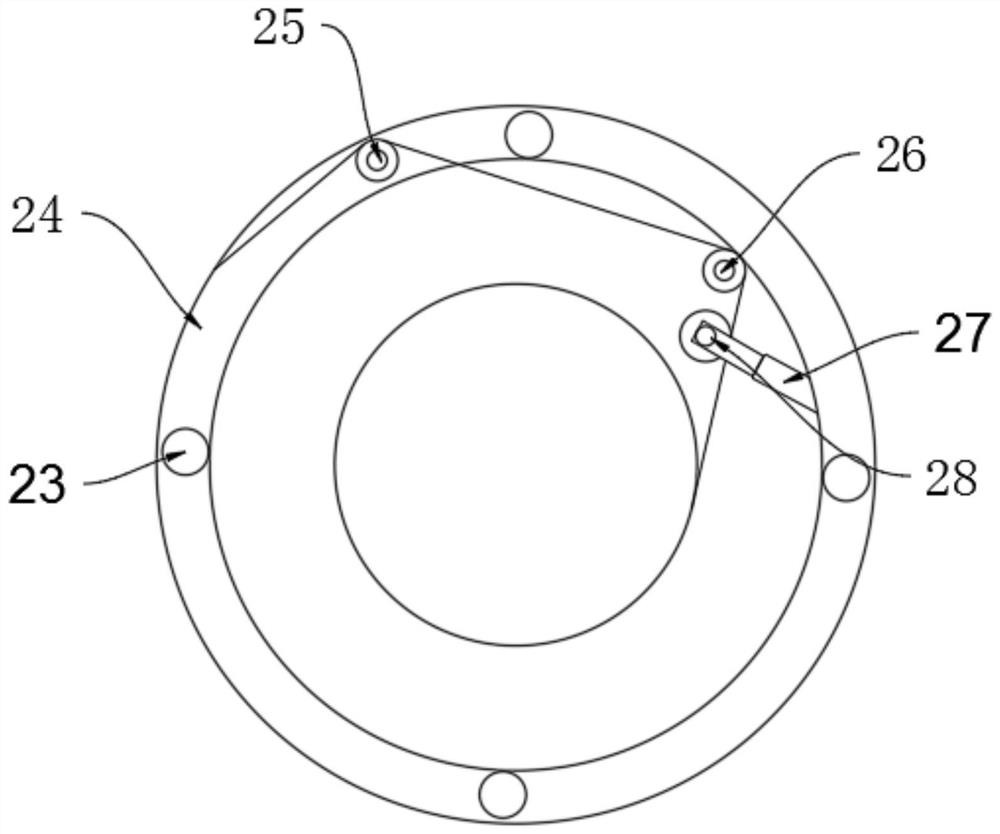

[0027] Compared with Embodiment 1, the improvement of this embodiment is that: the pay-off roller 24 is fixed with an elastic adjustment structure, and the elastic adjustment structure includes a clamping telescopic rod 27 and an adjustment roller 28, and the clamping telescopic rod 27 is fixed inside the winding placement roller 8, and the end of the clamping telescopic rod 27 is rotated to be provided with an adjustment roller 28, and a pressure sensor is fixed on the adjustment roller 28. The cable passes through the adjustment roller 28, the pressure sensor is used to detect the pressure of the cable, and the action of clamping the telescopic rod 27 is used to drive the adjustment roller 28 to elongate or shorten, so that the tensile force of the cable is fixed, avoiding the tension caused by the rope being too loose or Too tight affects the quality of winding.

[0028] The working principle of the present invention is: first, use the bottom motor 13 to raise the built-in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com