Method and device for carrying out cleaning operation for braking device of braking system, and motor vehicle system

A braking device and braking system technology, applied in the direction of automatic starting device, brake components, brakes, etc., can solve problems such as deceleration and braking pressure of motor vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

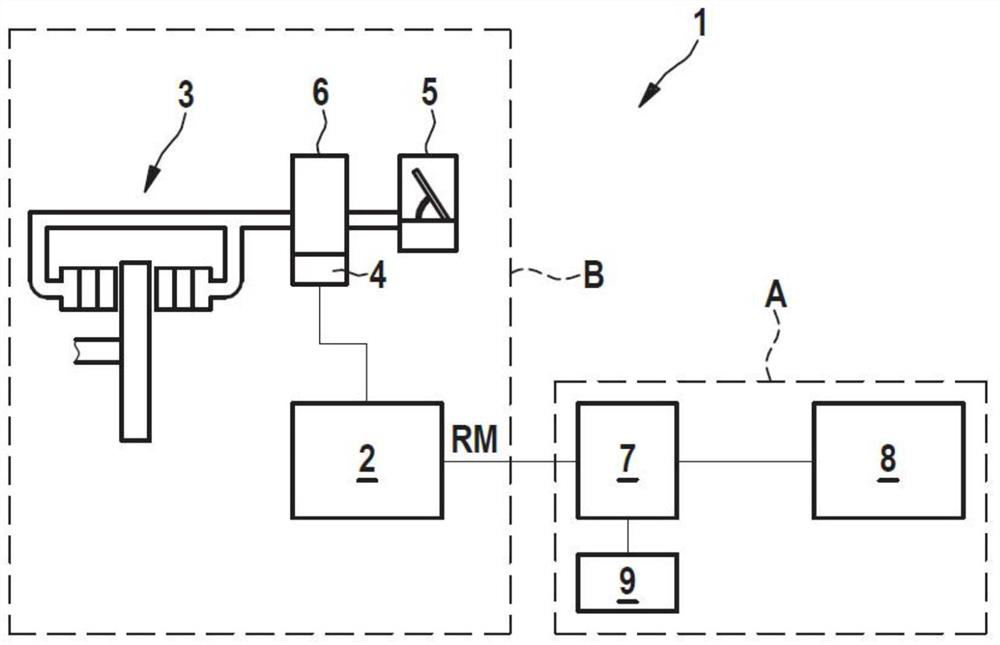

[0051] figure 1 A schematic diagram of a vehicle system 1 for a motor vehicle is shown. The vehicle system 1 has a brake system B with a brake control unit 2 and one or more brake devices 3 connected thereto ( figure 1 only one is shown). The braking device 3 can be designed in the form of a friction brake, in particular a disc brake.

[0052] The brake device 3 has parts that are movable relative to each other and are pressed against each other with brake pressure to generate friction. In particular, the brake device 3 can have a brake disc 31 and two brake shoes 32 which can be pressed hydraulically against the brake disc 31 . The frictional force generates a braking torque which acts on the wheels connected to the braking device 3 . The brake control unit 2 is designed to predetermine the brake pressure set by the brake actuator 4 . The control takes place in such a way that the brake shoe 32 is pressed against the friction surface of the brake disc 31 by the brake pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com