Hydraulic vehicle braking system with anti-locking arrangement

A hydraulic braking and anti-lock braking technology, applied in the direction of brakes, brake components, brake types, etc., can solve problems such as excessive tire wear, front wheel being locked, brake slipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

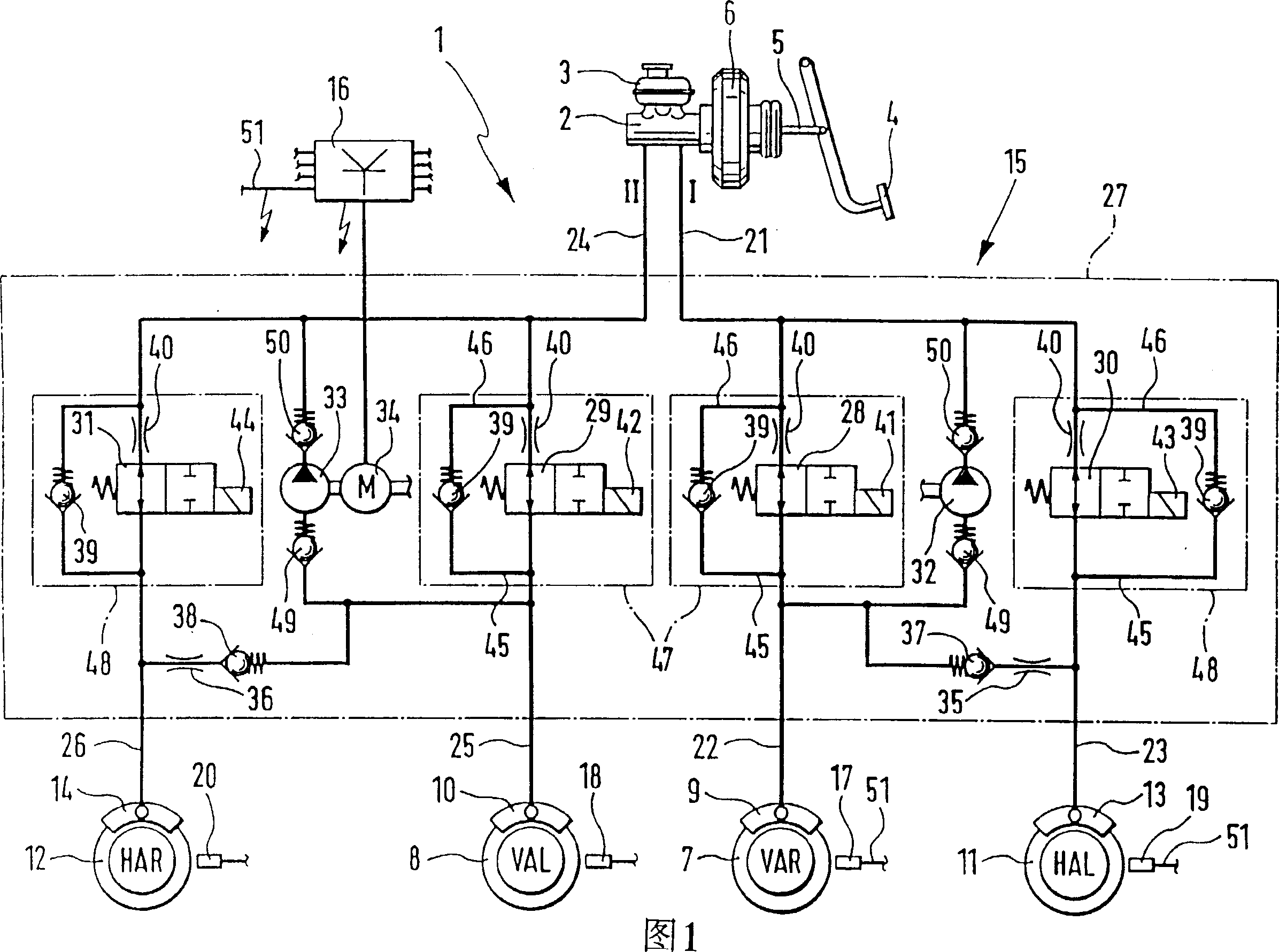

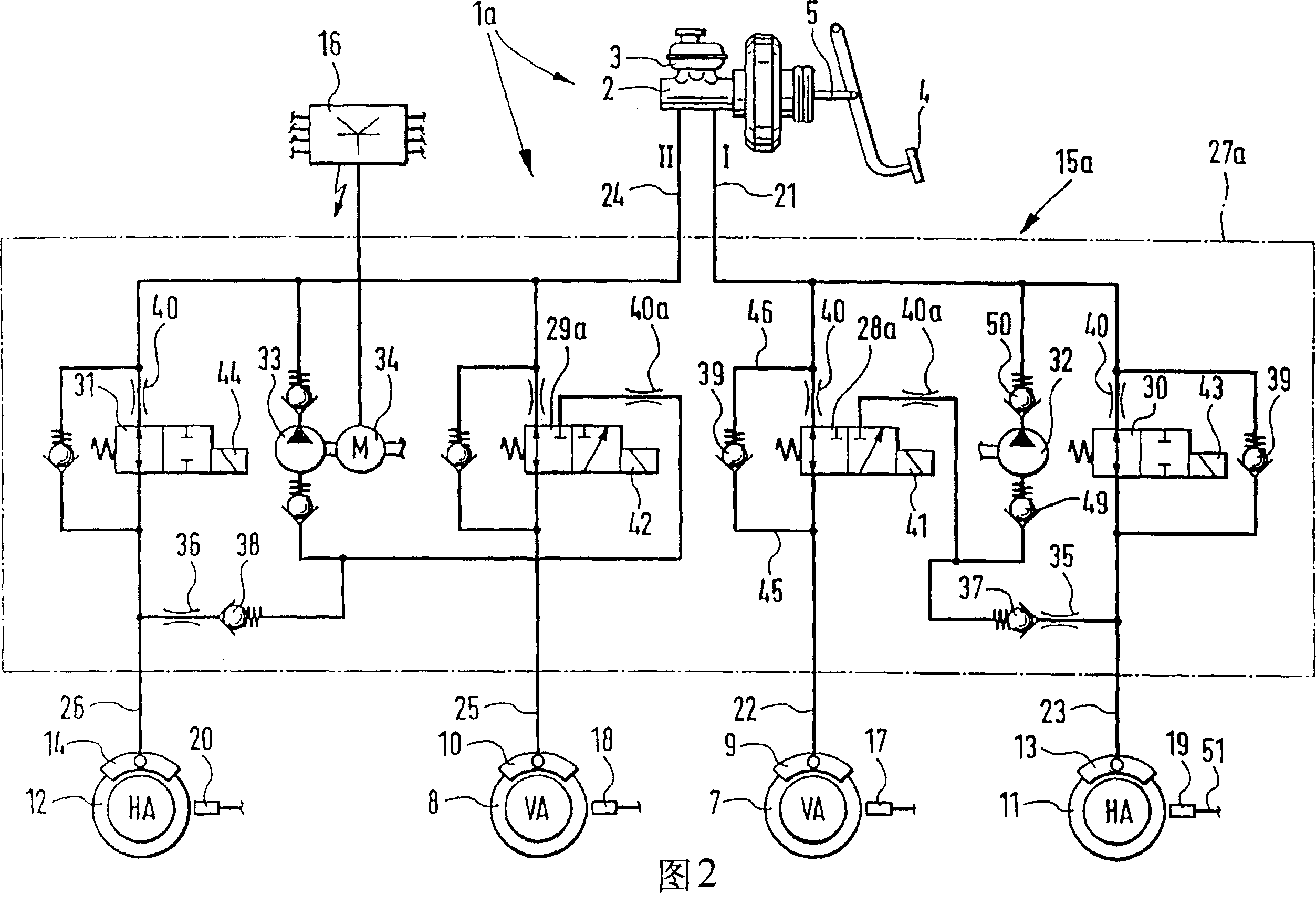

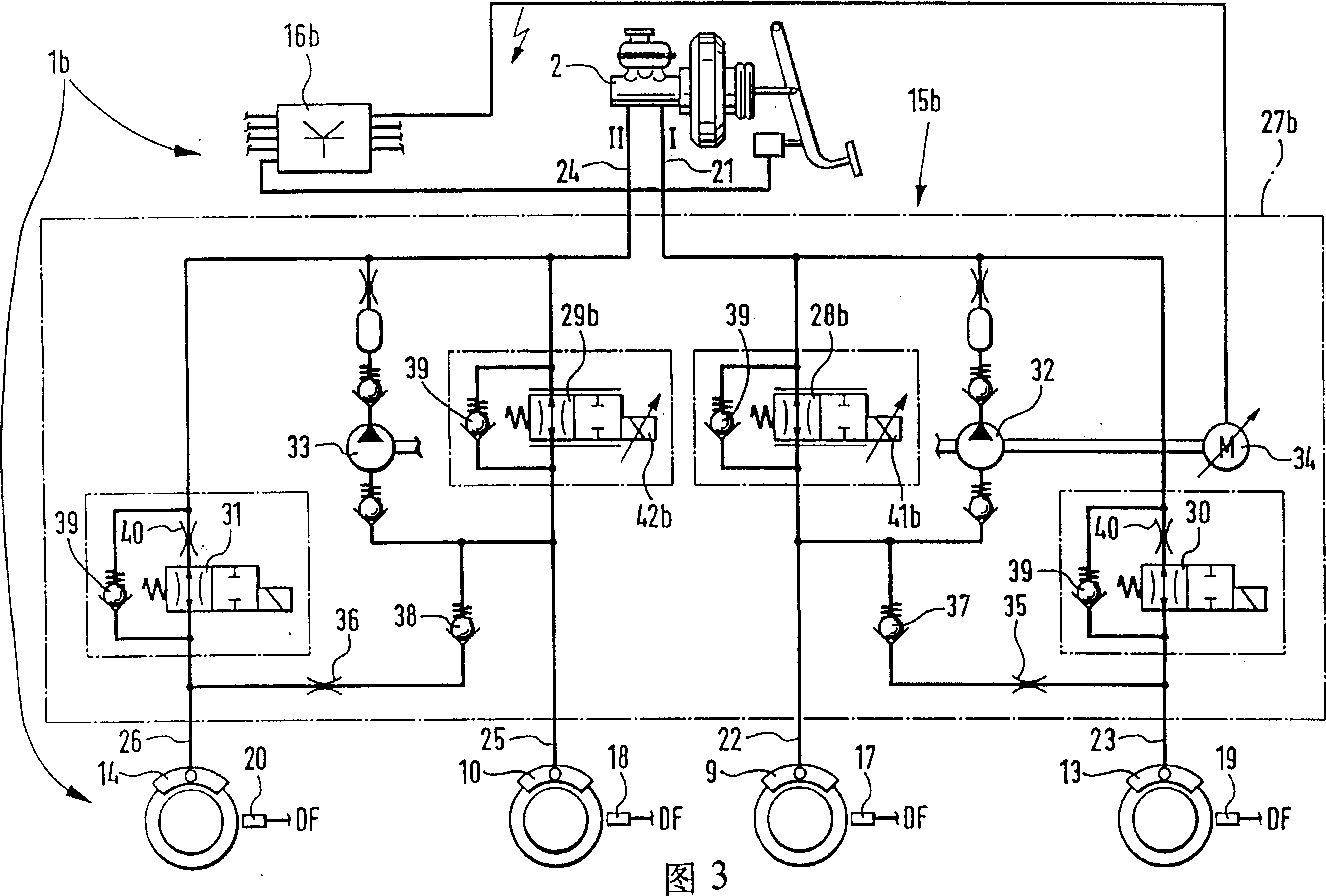

[0027] The automobile hydraulic braking system in Fig. 1 has a dual-circuit master brake cylinder 2 comprising a reserve oil tank 3, a brake pedal 4, a pedal lever 5, a brake force booster 6, two brake circuits I and II, Two front wheel brakes 7 and 8 with wheel brake cylinders 9 and 10, two rear wheel brakes 11 and 12 with wheel brake cylinders 13 and 14, an antilock device 15 and associated antilock brake Controller 16 of device 15 and wheel rotation sensors 17 , 18 , 19 and 20 .

[0028] Brake circuit 1 comprises a main brake circuit 21 that is sent from the main brake cylinder 2 and leads to the anti-lock brake device 15 and two wheels that are sent from the anti-lock brake device 15 and passed to the wheel brake cylinders 9 and 13. Moving circuits 22 and 23. Brake circuit II likewise includes a main brake circuit 24 and two wheel brake circuits 25 and 26 . Wheel brake circuit 25 leads to wheel brake cylinder 10 , and wheel brake circuit 26 leads to wheel brake cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com