Covering for a machine for producing a fibrous web and method for producing a covering of this type

A fiber web and stretching technology, which is applied in the field of machine stretching and can solve problems such as structural weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

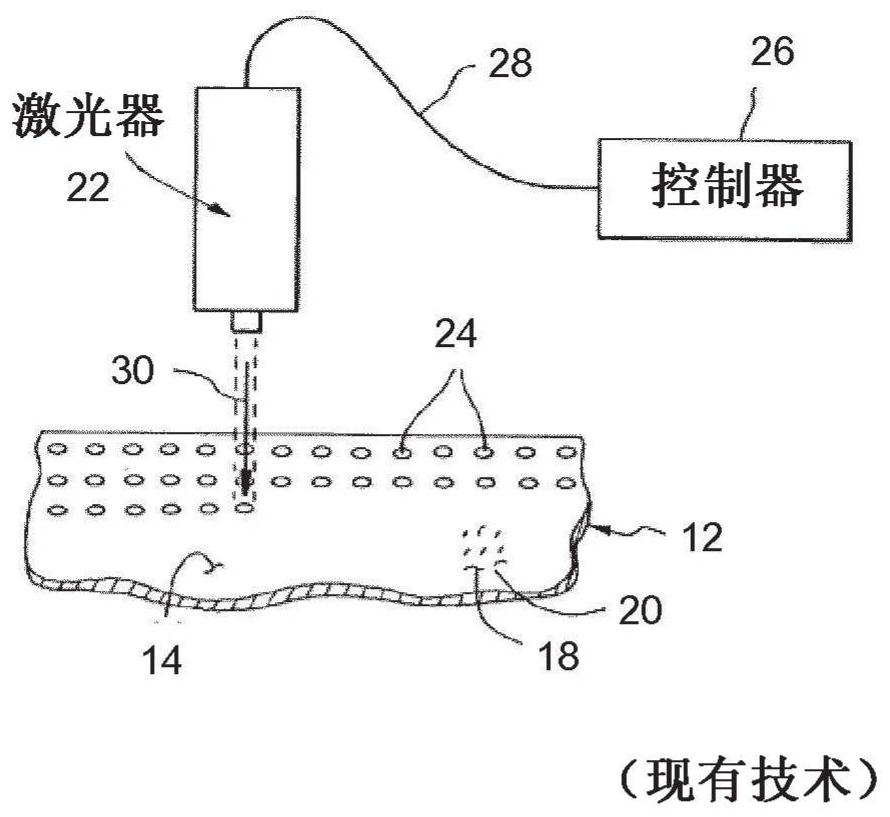

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

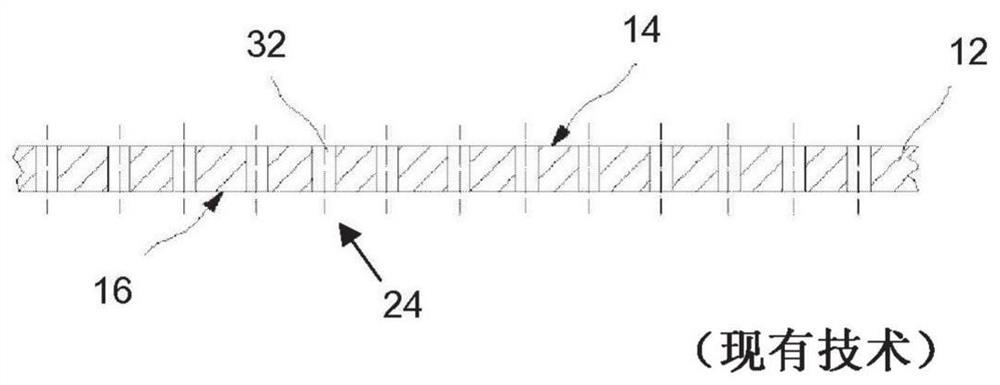

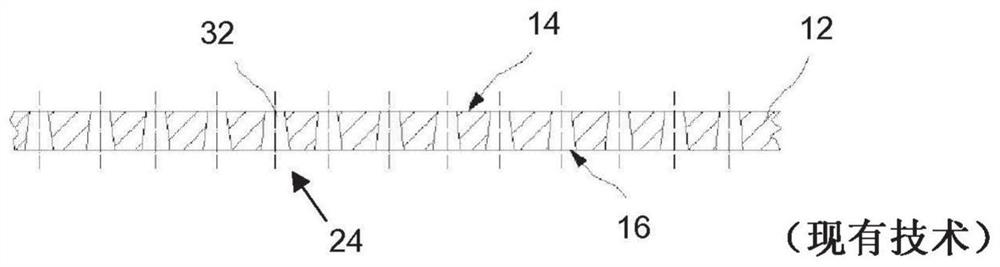

[0028] Figure 5A cross-sectional view of a section of the film-like material 12 along the longitudinal direction LR of the stretch web 10 according to the invention is schematically shown in . The stretched web 10 or the film-like material 12 has a first surface 14 and a second surface 16 opposite the first surface 14, the first surface facing the web formed on the stretched web 10 during intended use. Fiber web. Furthermore, it can be seen that between the first surface 14 and the second surface 16 six through-openings 24 extend through the film-like material 12 . Drainage of the fiber suspension for forming the fiber web can take place through these through openings 24 . Each through-opening 24 in this case has a respective, straight central axis 32 , which is shown by a dashed line in the figure. The walls of the through-openings 24 extend rotationally symmetrically about the respective central axis 32 . In the present exemplary embodiment, the through-openings 32 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com