Cement removing device for brick recycling and using method thereof

A technology for cleaning devices and bricks, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inability to adjust bricks flexibly, and achieve the effect of increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

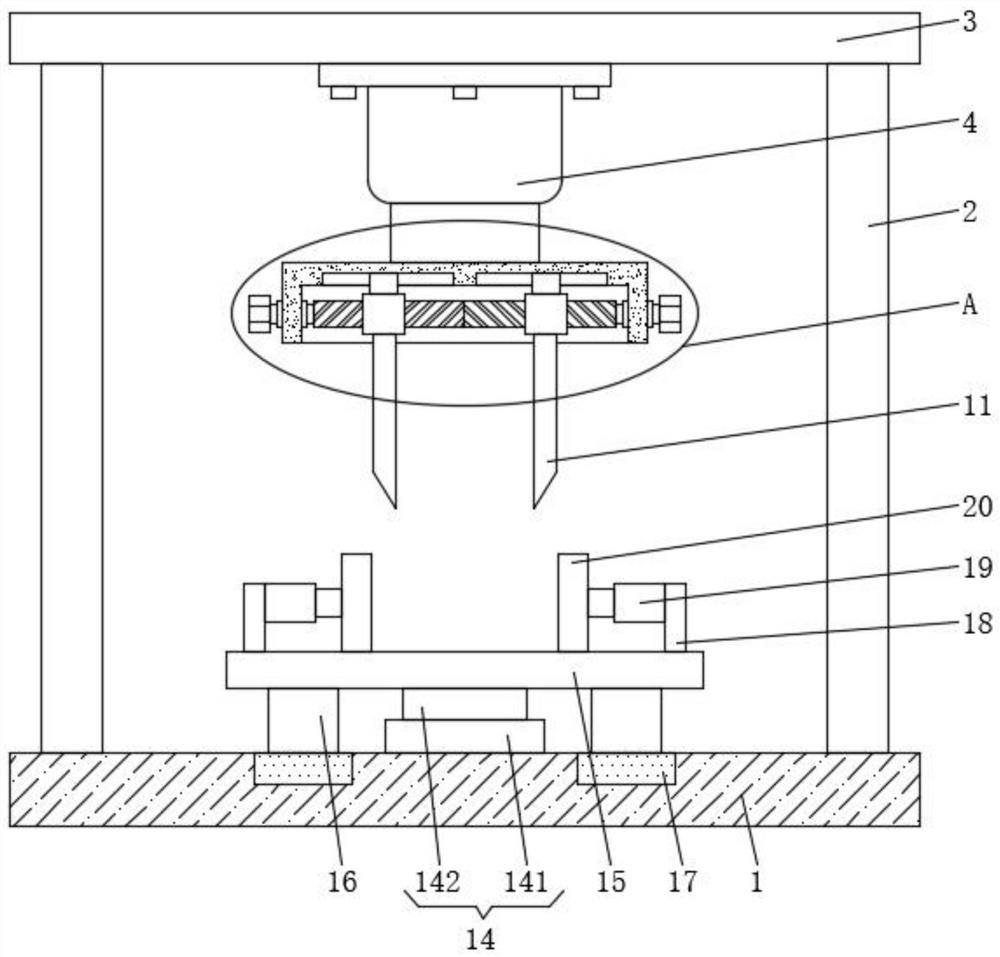

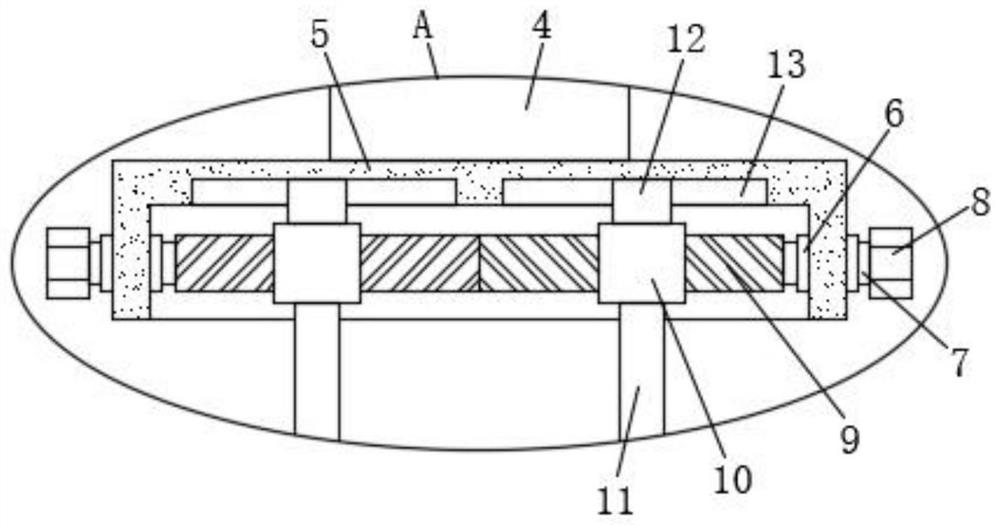

[0027] Such as Figure 1-3 As shown, the present invention provides a technical solution: a cement removal device for brick recovery, including a bottom plate 1, the four corners of the upper surface of the bottom plate 1 are fixedly connected with the lower surface of the top plate 3 through the support rod 2, and the lower surface of the top plate 3 The surface is provided with a hydraulic rod 4, by setting the hydraulic rod 4, controlling the extension or shortening of the hydraulic rod 4, the housing 5 can be flexibly controlled to move up and down, so that the cutter 11 on the housing 5 can remove the cement on the bricks, The bottom end of the hydraulic rod 4 is fixedly connected with the casing 5, the left and right sides of the inner wall of the casing 5 are clamped with the first bearing 6, the first rotating shaft 7 is sleeved in the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com