Thread residue collecting device for textile production

A technology for collecting devices and textiles, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc., can solve the problems of difficulty in cleaning, easy access to the inside of human mouth and nose equipment, damage, etc. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

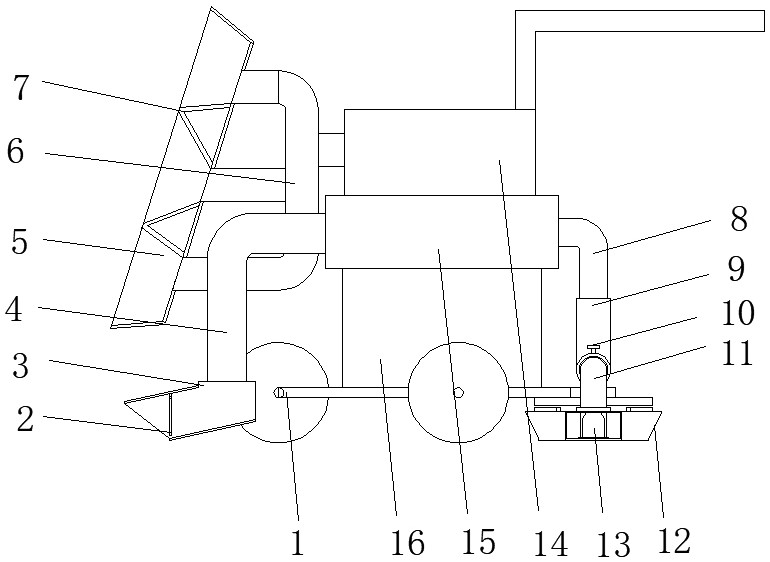

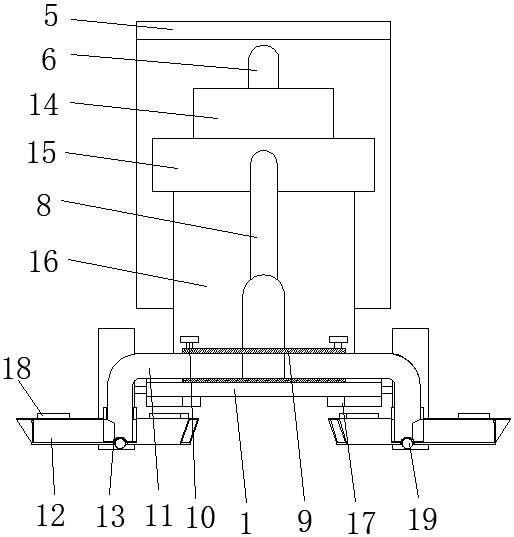

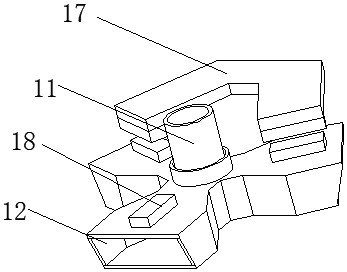

[0026] refer to Figure 1-4 , a thread collection device for textile production, comprising a frame 1, a vacuum cleaner 16 is fixedly installed on the top of the frame 1, and an exhaust hood 15 is fixedly installed on the top of the vacuum cleaner 16, and L-shaped The first suction pipe 4 and the second suction pipe 8 of the structure, the bottom end of the first suction pipe 4 is fixedly installed with the main collection tank 3 which is arranged obliquely, and the bottom of the second suction pipe 8 is fixedly installed with a three-way joint 9 , and both ends of the three-way joint 9 are plugged with extension pipes 11, the top of the three-way joint 9 is screwed with fastening bolts 10, the extension pipe 11 has an L-shaped structure, and the outside of the bottom end of the extension pipe 11 is sealed The bearing is equipped with a sub-collection tank 12, and the side of the vertical section of the extension pipe 11 is provided with a suction tank 13, and the suction tank...

Embodiment 2

[0034] refer to Figure 1-5 , a thread collection device for textile production. Compared with Example 1, the interior of the dust box 5 is fixedly equipped with a plurality of triangular-shaped dividing plates 7, and the side of the third suction pipe 6 is provided with A plurality of suction branch pipes interlaced with the partition plates 7, in the device rely on a plurality of partition plates 7 to isolate multiple independent areas inside the dust collection box 5, thereby increasing the suction force within the dust collection box 5 range, improving Dust collecting box 5 is to the collection efficiency of floating dust and lint.

[0035] When this embodiment is in use, the device relies on a plurality of partition plates 7 to isolate a plurality of independent areas inside the dust box 5, and generates suction in each independent area through the suction branch pipe, thereby increasing the dust within the scope of the dust box 5. The suction strength is improved, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com