Multi-mode continuous casting and rolling control method for plate strip

A continuous casting and rolling, control method technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems affecting the continuity and production efficiency of endless rolling, the lack of transient mutation control ability of equipment system, Problems such as non-uniform distribution of strip temperature can achieve the effect of coordinated and flexible production line configuration, widening the coverage of product thickness, and optimizing production line configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

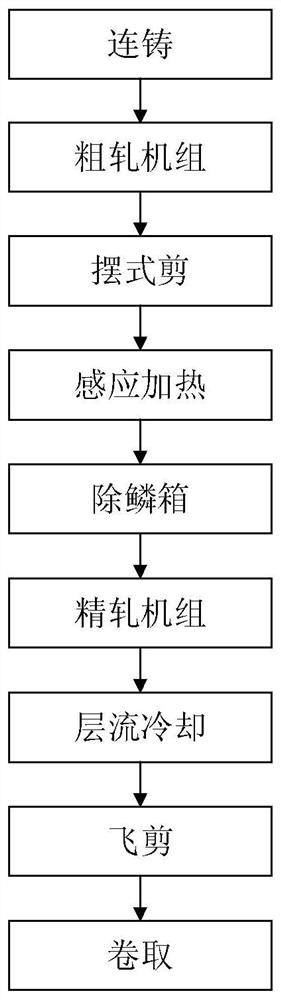

specific Embodiment 1

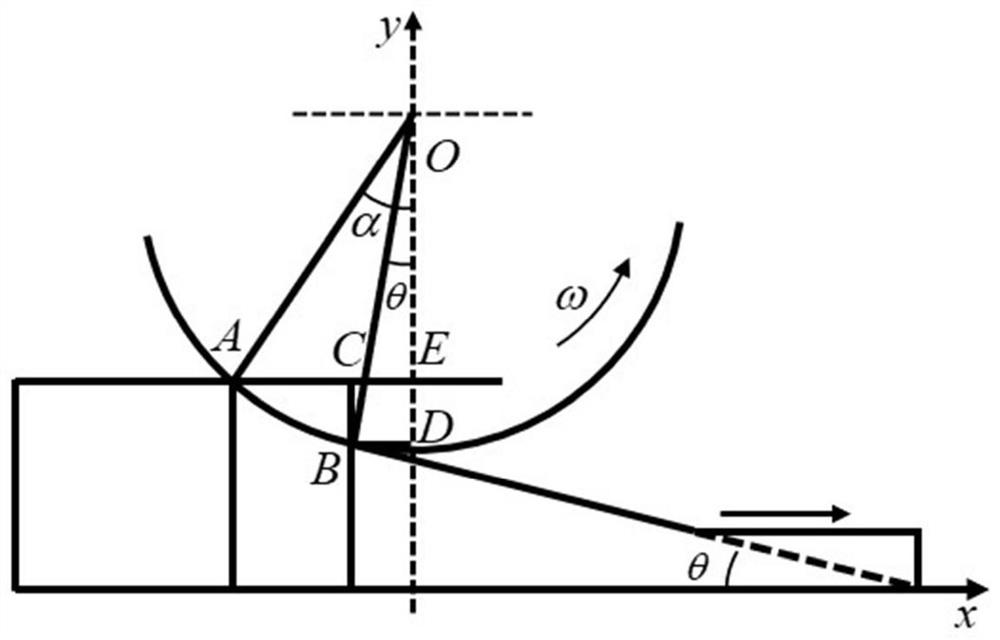

[0097] In the endless rolling mode, when the rolls of the finishing mill are worn out, the transient sudden change and dynamic change schedule adjustment is performed. The transient sudden change dynamic change schedule strategy of the finish rolling mill is the downstream adjustment mode. When F2 is the standby finishing mill, F3 is worn out. In the finishing mill, the surface temperature of the strip increases while the core temperature decreases during the lifting of the F3 rolls, and the surface temperature of the strip decreases and the core temperature increases during the pressing of the F2 rolls. In order to ensure temperature uniformity, the spray header located in front of the F2 finishing mill stops spraying cooling water on the strip before the F2 roll is pressed down, and at the same time the F2 roll is pressed down to finish the strip, and the F3 roll is located before The injection header in front of it starts to spray cooling water, and at the same time, the F3 ...

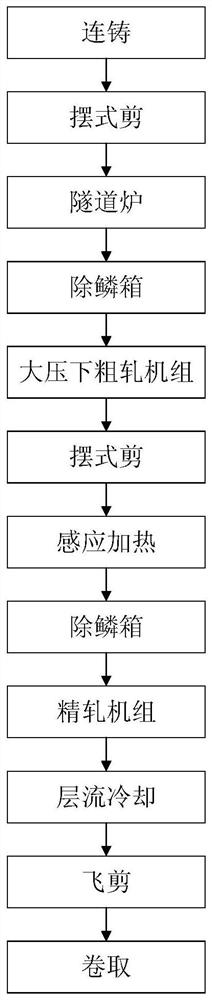

specific Embodiment 2

[0099] In the endless rolling mode, when the rolls of the finishing mill are worn out, the transient sudden change and dynamic change schedule adjustment is performed. The transient sudden change dynamic change schedule strategy of the finish rolling mill is the downstream adjustment mode. When F2 is the standby finishing mill, F3 is worn out. In the finishing mill, the surface temperature of the strip increases while the core temperature decreases during the lifting of the F3 rolls, and the surface temperature of the strip decreases and the core temperature increases during the pressing of the F2 rolls. In order to ensure temperature uniformity, the spray header located in front of the F2 finishing mill stops spraying cooling water on the strip before the F2 roll is pressed down, and at the same time the F2 roll is pressed down to finish the strip, and the F3 roll is located before The injection header in front of it starts to spray cooling water, and at the same time, the F3 ...

specific Embodiment 3

[0101] In the endless rolling mode, when the rolls of the finishing mill are worn out, the transient sudden change and dynamic change schedule adjustment is performed. The transient sudden change dynamic change schedule strategy of the finish rolling mill is the downstream adjustment mode. When F2 is the standby finishing mill, F3 is worn out. In the finishing mill, the surface temperature of the strip increases while the core temperature decreases during the lifting of the F3 rolls, and the surface temperature of the strip decreases and the core temperature increases during the pressing of the F2 rolls. In order to ensure temperature uniformity, the spray header located in front of the F2 finishing mill stops spraying cooling water on the strip before the F2 roll is pressed down, and at the same time the F2 roll is pressed down to finish the strip, and the F3 roll is located before The injection header in front of it starts to spray cooling water, and at the same time, the F3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com