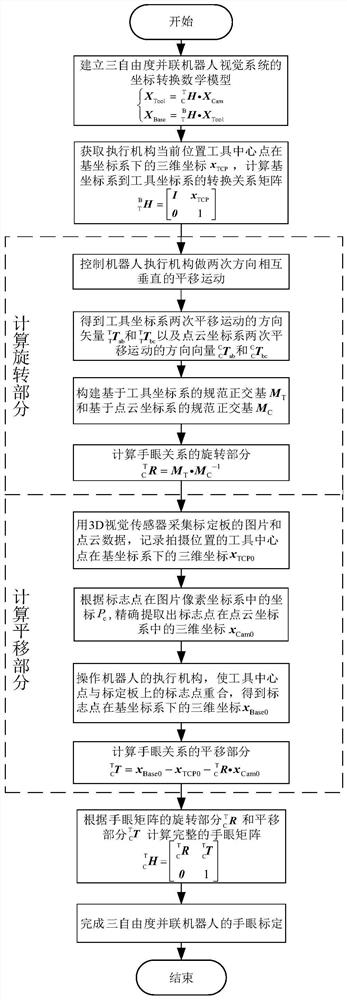

Three-degree-of-freedom parallel robot hand-eye calibration method based on 3D visual sensor

A visual sensor and robot technology, applied in the field of robot vision, can solve the problems that the three-degree-of-freedom parallel robot cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

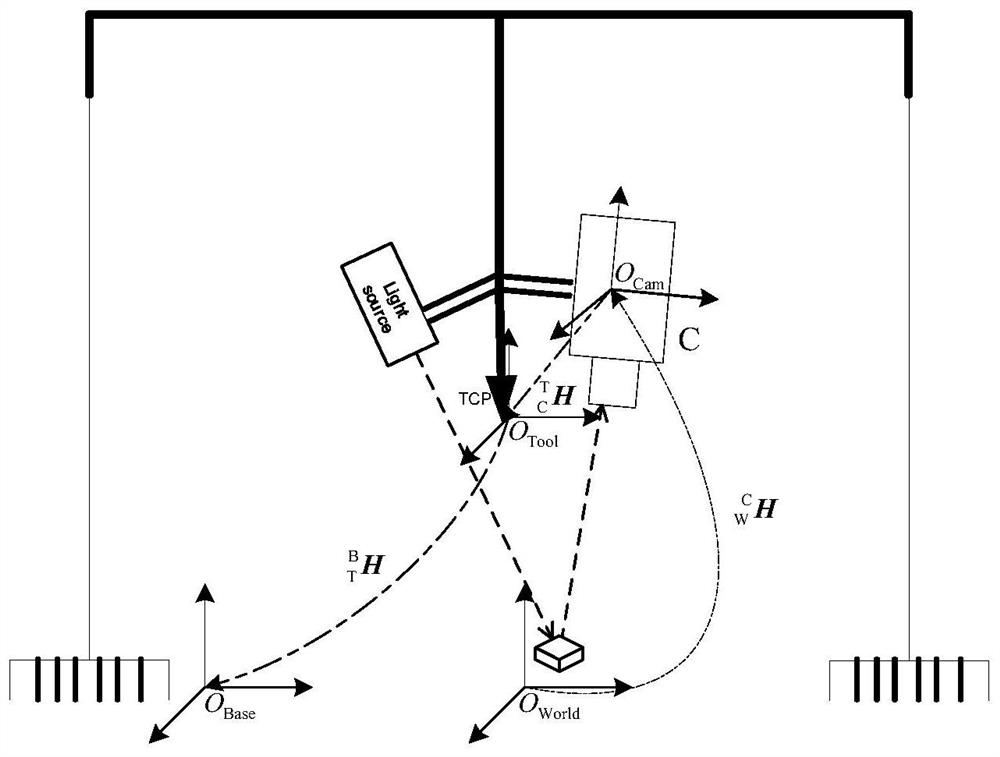

Method used

Image

Examples

Embodiment

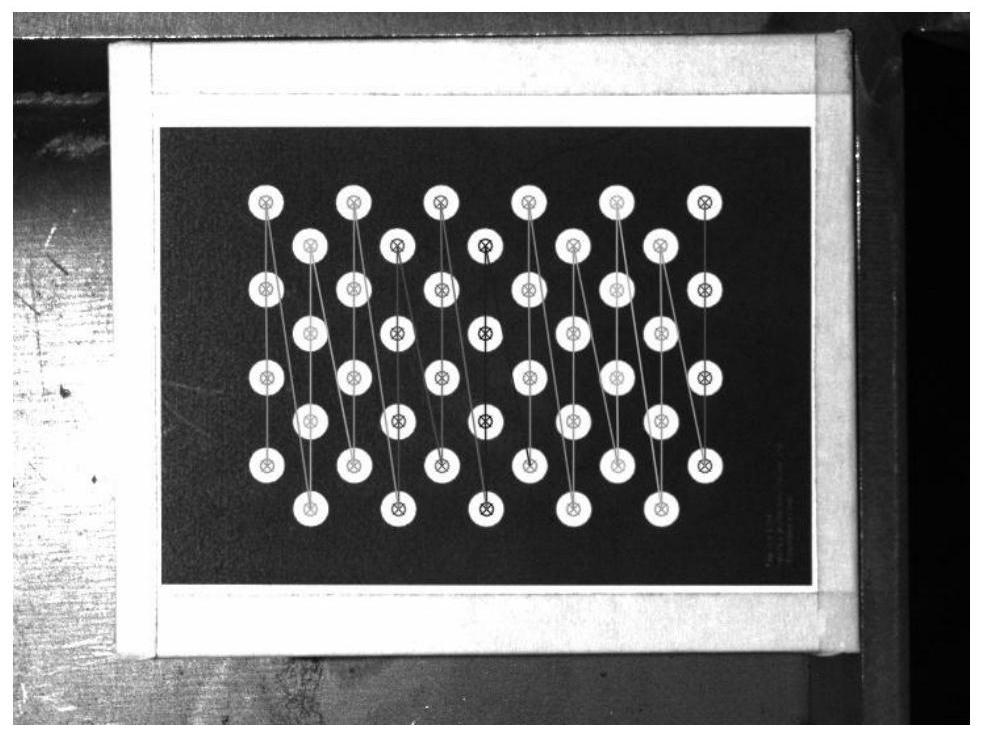

[0064]Using this method to carry out the calibration experiment, the repeated positioning accuracy of the three-degree-of-freedom parallel robot used in the experiment is ±0.01mm, the image resolution of the 3D sensor is 728×544, the number of point cloud imaging points is 396032, and the standard working distance is 44mm. Select 16 test points, first measure the three-dimensional coordinates x' of the test points in the base coordinate system by contact Base , and then calculate the three-dimensional coordinate x" of the test point measured by the hand-eye vision system in the base coordinate system through formula (1) Base , the method to calculate the absolute error e of the test point is:

[0065] e=|x" Base -x' Base | (16)

[0066] Using this method to calibrate the results, the average absolute error of 16 test points is 0.119mm, and the maximum absolute error is 0.174mm. As a comparison, the method of approximate rounding of sub-pixels is also tested, and the averag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com