Conical net making machine

A conical netting machine technology, applied in the field of netting machines, can solve problems such as high scrap rate, tape viscosity decrease, filter screen offset, etc., and achieve the effects of short nailing cycle, cost saving and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

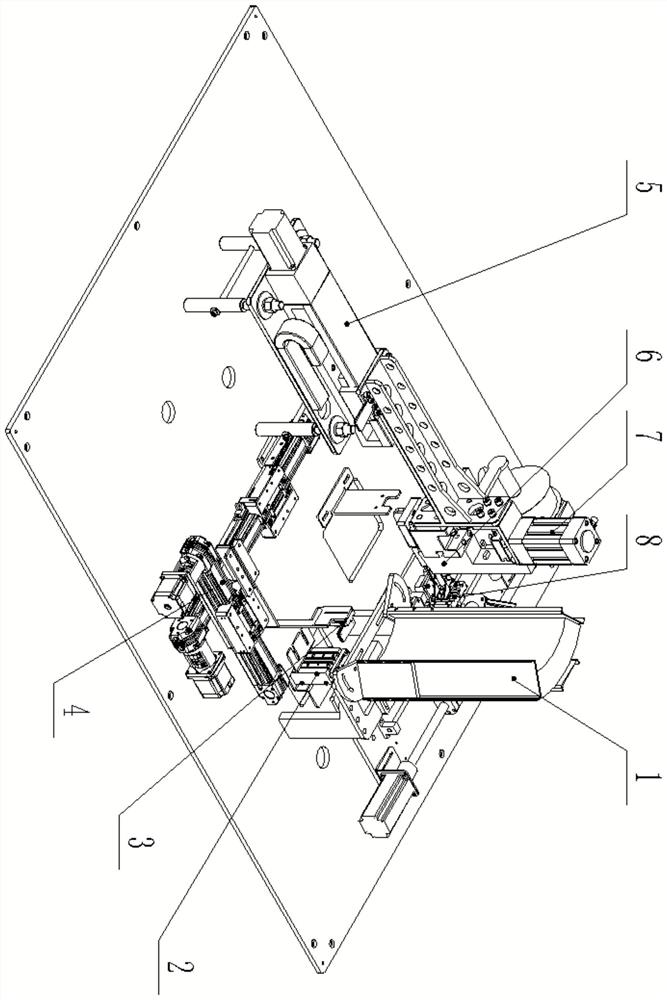

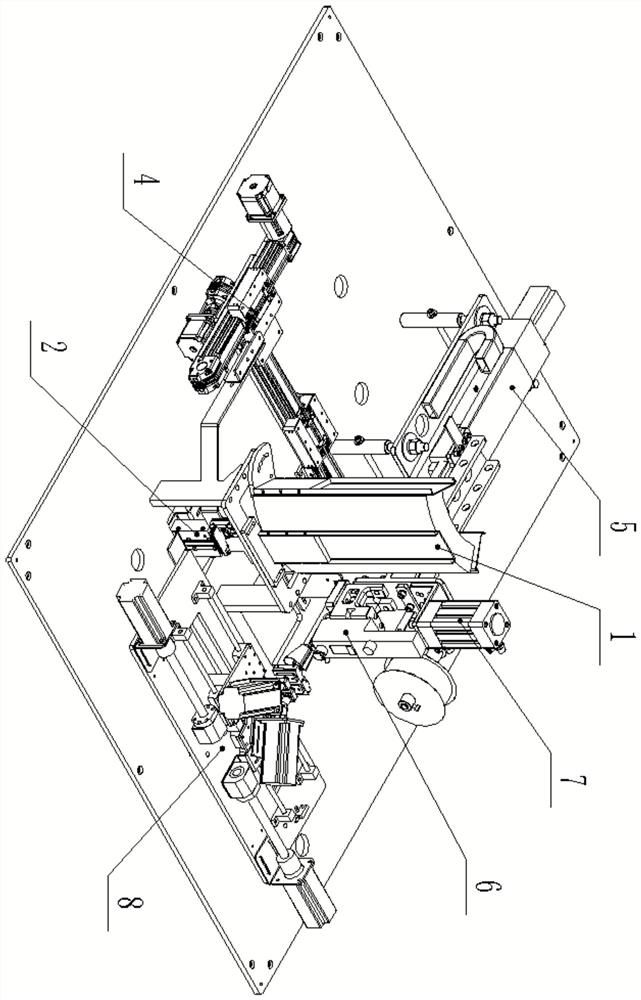

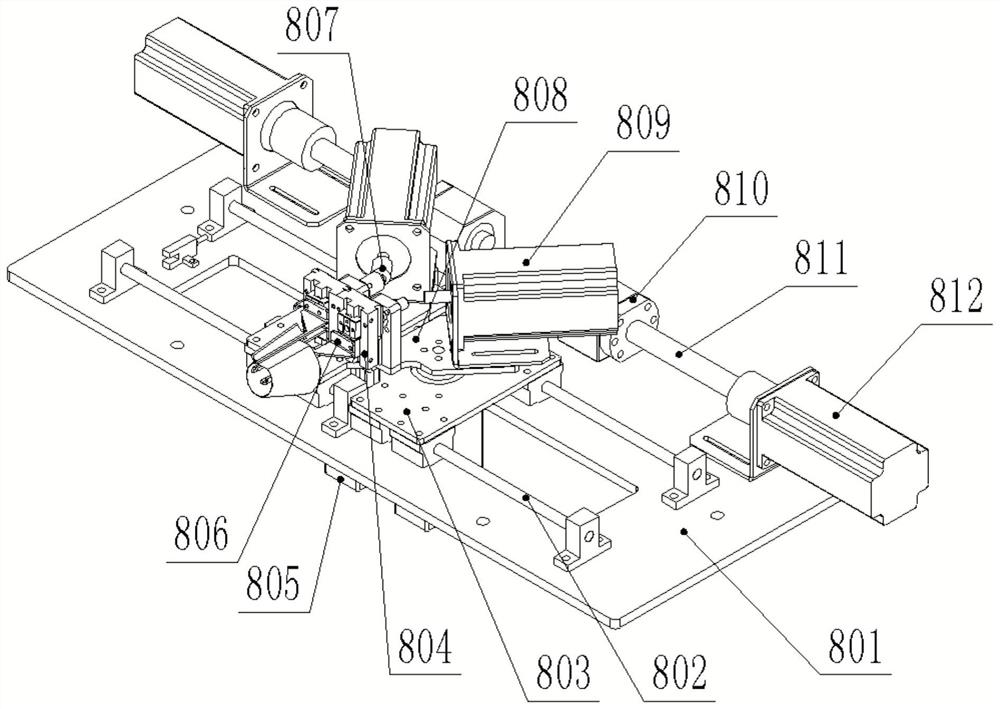

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0047] A cone-shaped net making machine, including:

[0048] The filter silo 1 is used to store filters. In order to be compatible with filters of different tapers and sizes, the shape and size of the filter silo 1 can be adjusted. Specifically, the filter silo 1 includes: a support plate 101 provided at the bottom for supporting. The plate 101 is equipped with a first baffle 102 and a second baffle 103 which are vertically arranged. The lower end of the first baffle 102 is provided with an arc slot 105 and a round hole 106, and the arc slot 105 and the round hole 106 are inserted A bolt is installed, and the lower end of the bolt is threadedly connected with the supporting plate 101. The first baffle 102 can rotate around the axis of the circular hole 106, and the rotation angle of the first baffle 102 can be fixed by the bolts in the arc-shaped slot 105. The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com