Screen stapling machine and working method thereof

A technology of net machine and stapler, which is applied in the field of net nailing machines, can solve the problems of affecting the retrieving effect, high waste rate, and decreased adhesive tape viscosity, and achieves adjustable filter mesh overlap, short nailing cycle, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in further detail below in conjunction with the accompanying drawings.

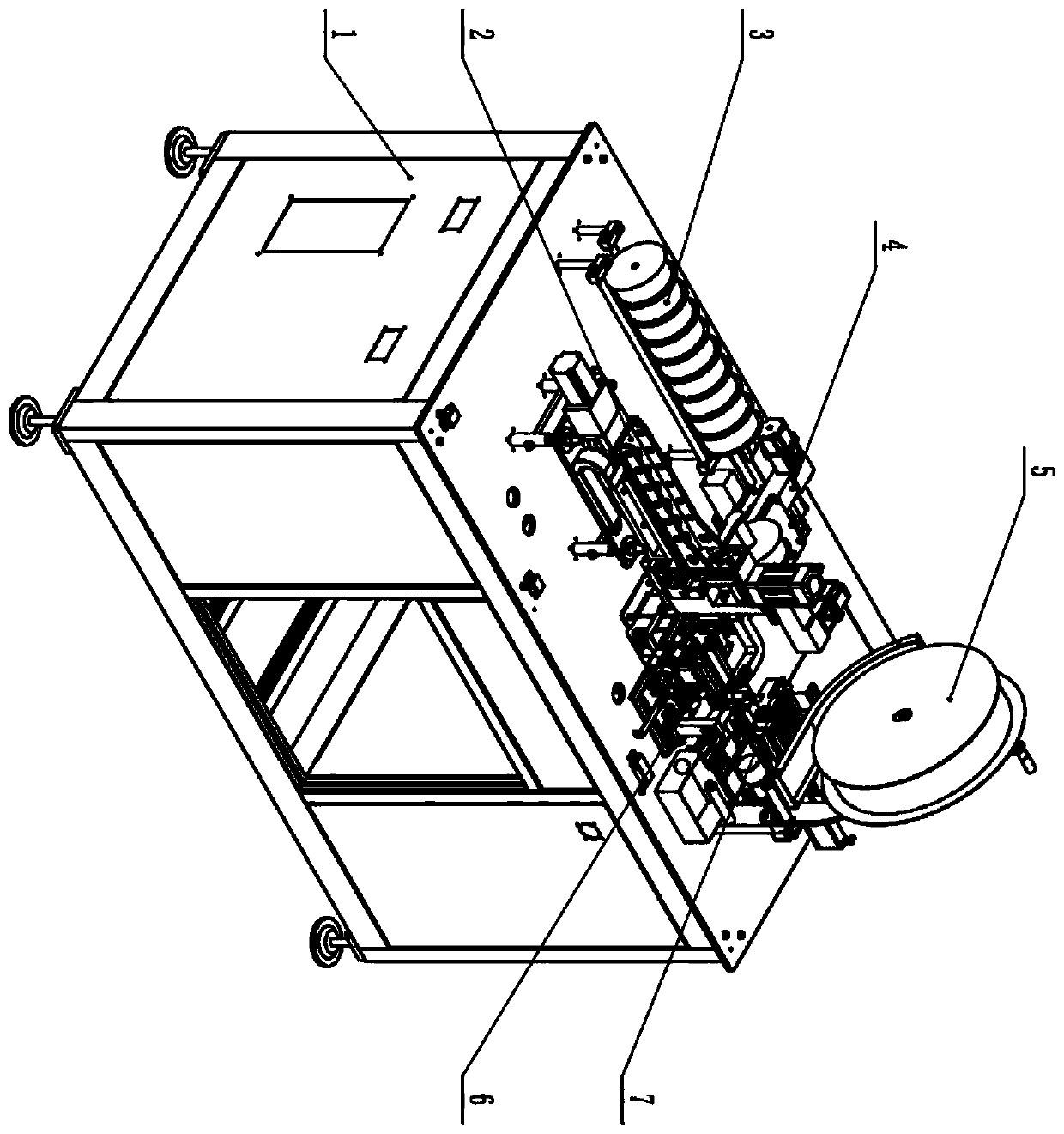

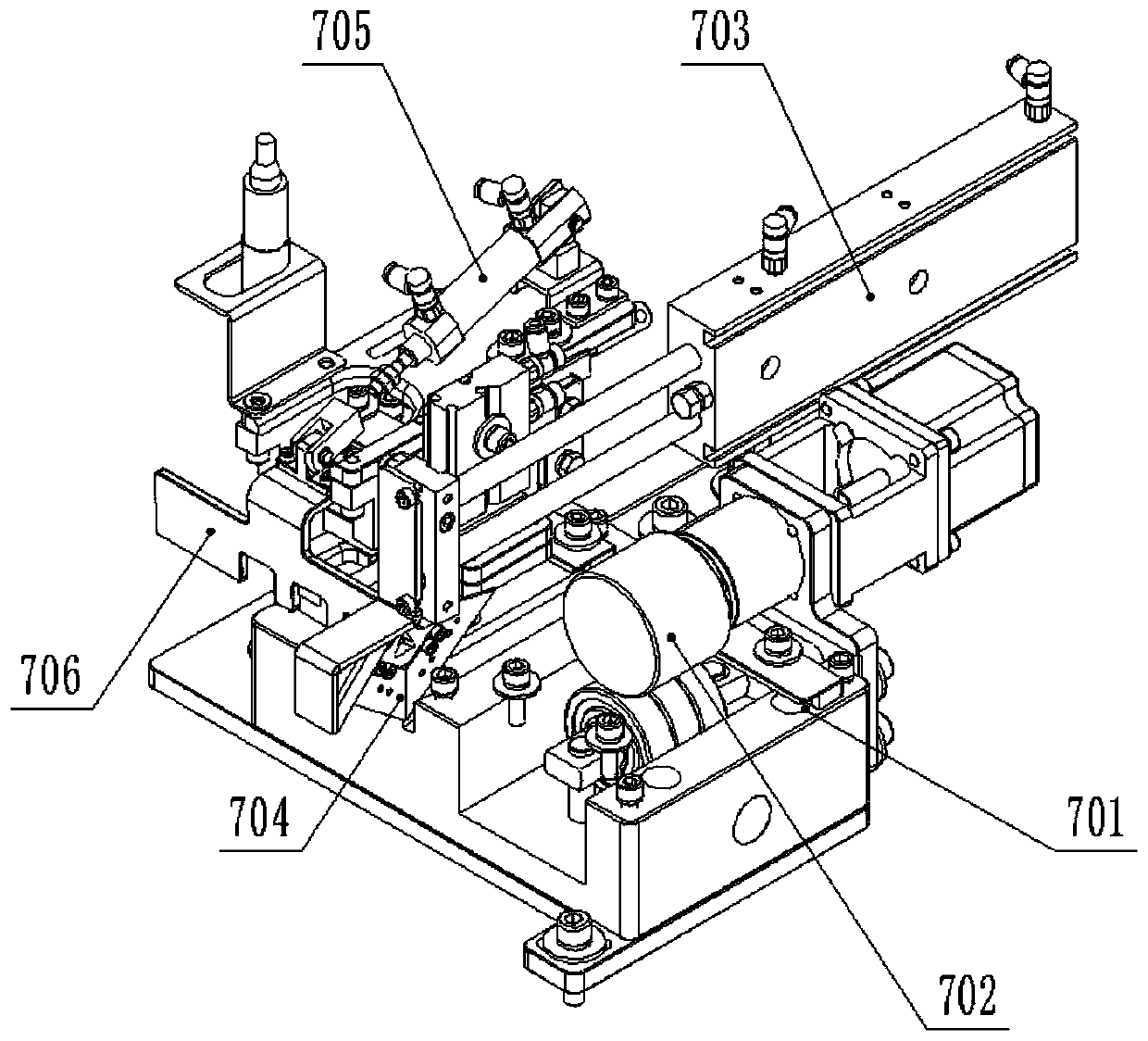

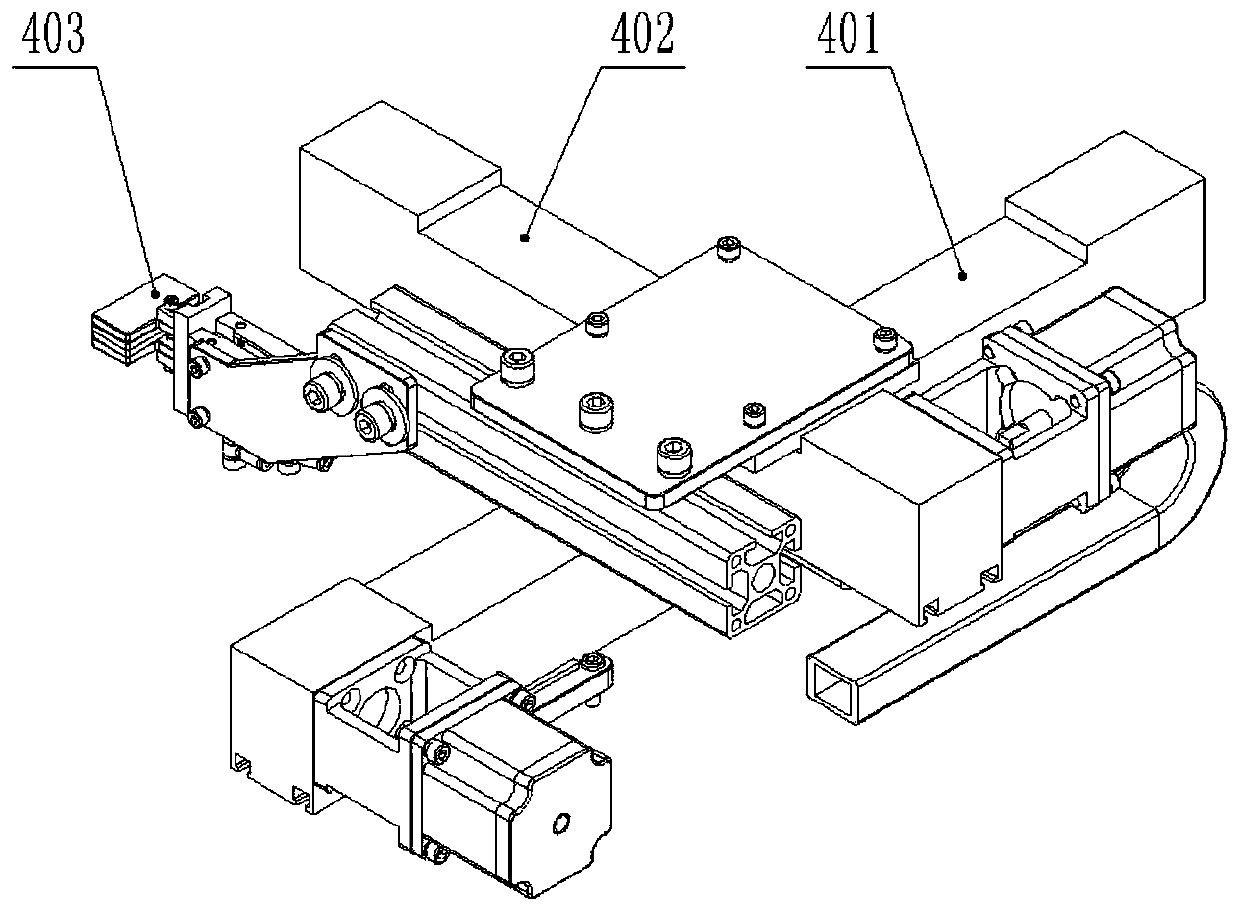

[0075] Such as figure 1 As shown, a nailing machine includes: a frame 1, and the frame 1 is all made of aluminum alloy, which greatly reduces the weight of the equipment and has a beautiful appearance. The filter screen hopper 5 arranged on the frame 1 is used to place the rolled filter screen 101. When a roll of filter screen 101 is used up, it can be replaced quickly for easy operation; Net assembly 7, it is used to cut filter screen 101 into rectangular filter screen sheet 102; The filter screen transfer assembly 4 that is arranged on the frame 1, it is used for filter screen sheet 102 is moved to roll net from net cutting assembly 7 Component 6; the rolling net component 6 arranged on the frame 1, which is used to roll the filter screen sheet 102 into a filter screen cylinder 103; the stapler assembly 2 arranged on the frame 1, which is used to filter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com