An integrated powder-loaded enhanced biochemical water treatment device

A water treatment device and attached technology, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problems of ineffective denitrification of sewage, low treatment efficiency, and land occupation Large area and other problems, to achieve the effect of increased sewage treatment capacity, good settlement performance, and high volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

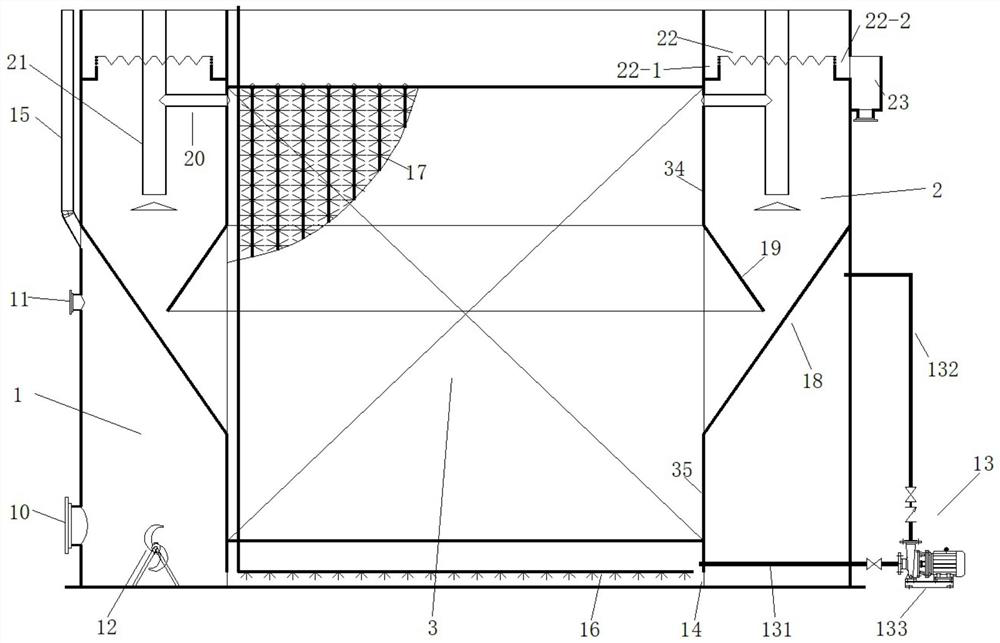

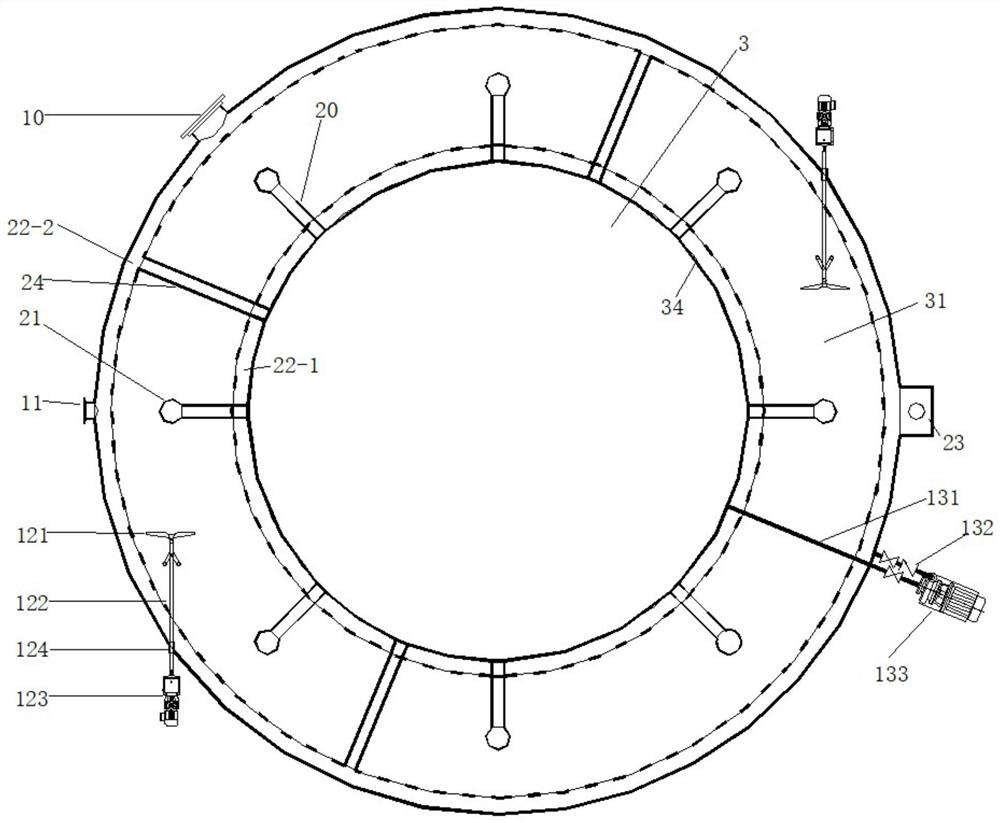

[0032]Such asFigure 1-2As shown, a longitudinal cross-sectional view of an integrated powder provided by the present embodiment, the device is a cylindrical, including a central cylindrical center aerobic region 3, anoxic oxygen surrounding aerobic region 3 / The sedimentation zone 31, the oxygen / precipitation zone 31 includes a hypoxic region 1 with an inlet portion 11, a precipitation region 2 at the upper portion of the hypoxic region 1, further comprising a bottom overflow of the oxygen-deficient zone 1 and the aerobic region 3. The aperture 14, reflows the nitrification fluid in the aerobic region 3 to the reflow system 13 in the oxygen-deficient zone 1; the aerobic region 3 is inclined to the outer axis of the apparatus 55 in the axis of the apparatus through the partition, the oxygen / precipitation region 31. The slider plate 19 is separated from the partition plate 18 and the partitioned spacer 35 in the inner side of the axis in the apparatus, and the slurry plate 19 is ...

Embodiment 2

[0046]The difference between the embodiment and the first embodiment is that the volume ratio of the antoxic region 1 and the aerobic region 3 is 1: 3.5, the surface load of the precipitation zone 2 is 1.3m.3 / M2· H, the device is used to denitrify / nitrate, the volumetric load is 1.2kg BOD5 / M3· The tilt angle in the outer side of the axis of the device is 65 °, and the inclination angle in the inner side of the axis of the apparatus is 65 °.

[0047]The soil flow rate of the discharge stirrer 12 is 0.32 m / s, and the mixed sewage in the device is 0.6 m / s through the bottom overflow 14.

Embodiment 3

[0049]The difference between the present embodiment and the second embodiment and the second embodiment is that the volume ratio of the hypoxic region 1 and the aerobic region 3 is 1: 5, the surface load of the precipitation zone 2 is 2.6m.3 / M2· H, the device is required to be 2.4 kgbod when denitrification / nitrifying biodeprofrination5 / M3· The tilt angle of the D slog 19 to the outer side of the axis of the device is 60 °, and the tilt angle of the partition separator 18 toward the inner side of the apparatus is 55 °.

[0050]The soil flow rate of the flow mixer 12 is 0.4 m / s, and the mixed sewage in the device passes through the bottom overflow hole 14 is 0.8 m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com