Circle-center-variable drop-shaped infolding gear rotating mechanism

A rotating mechanism and drop-shaped technology, which is applied in the direction of mechanical equipment, shafts, bearings, pivots, etc., can solve the problem of high requirements for the inner bending mechanism, achieve simple and effective overall structure design, meet service life requirements, and reduce processing difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

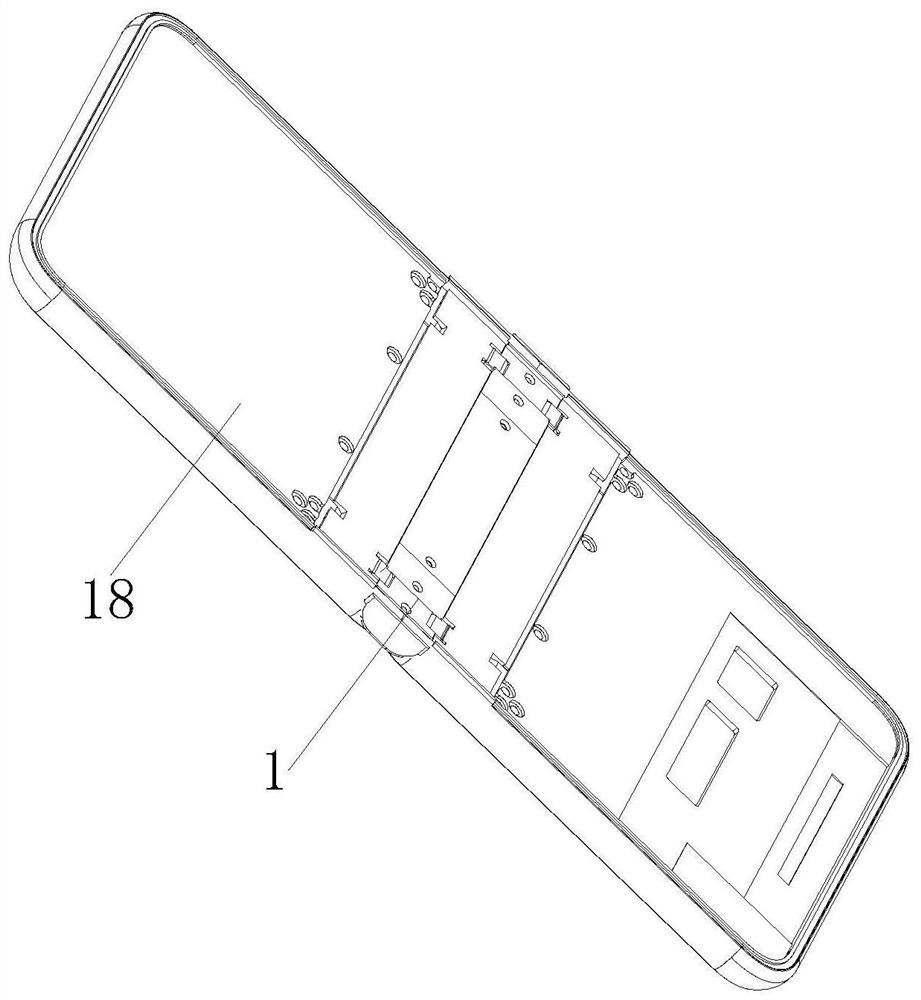

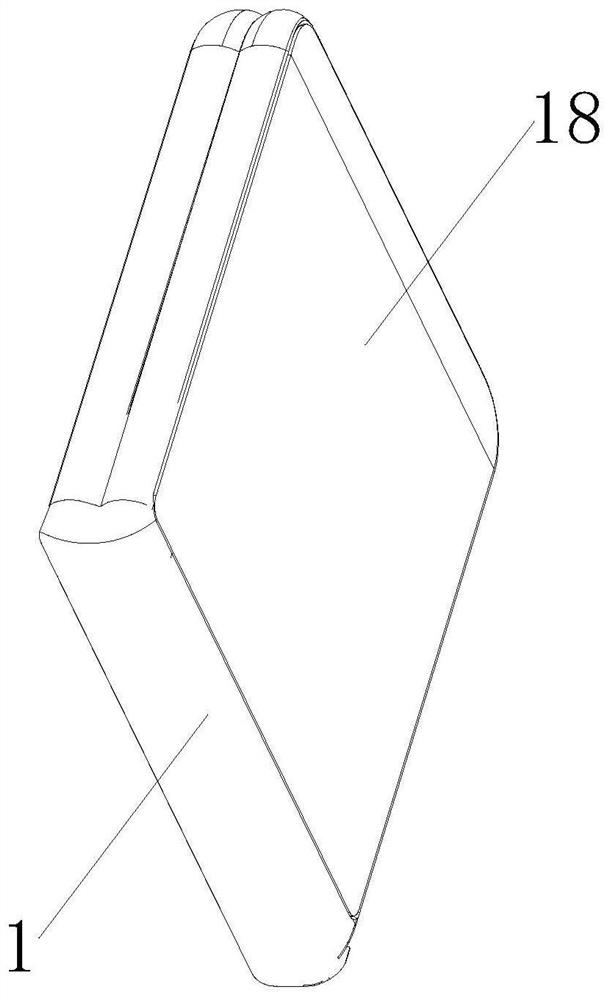

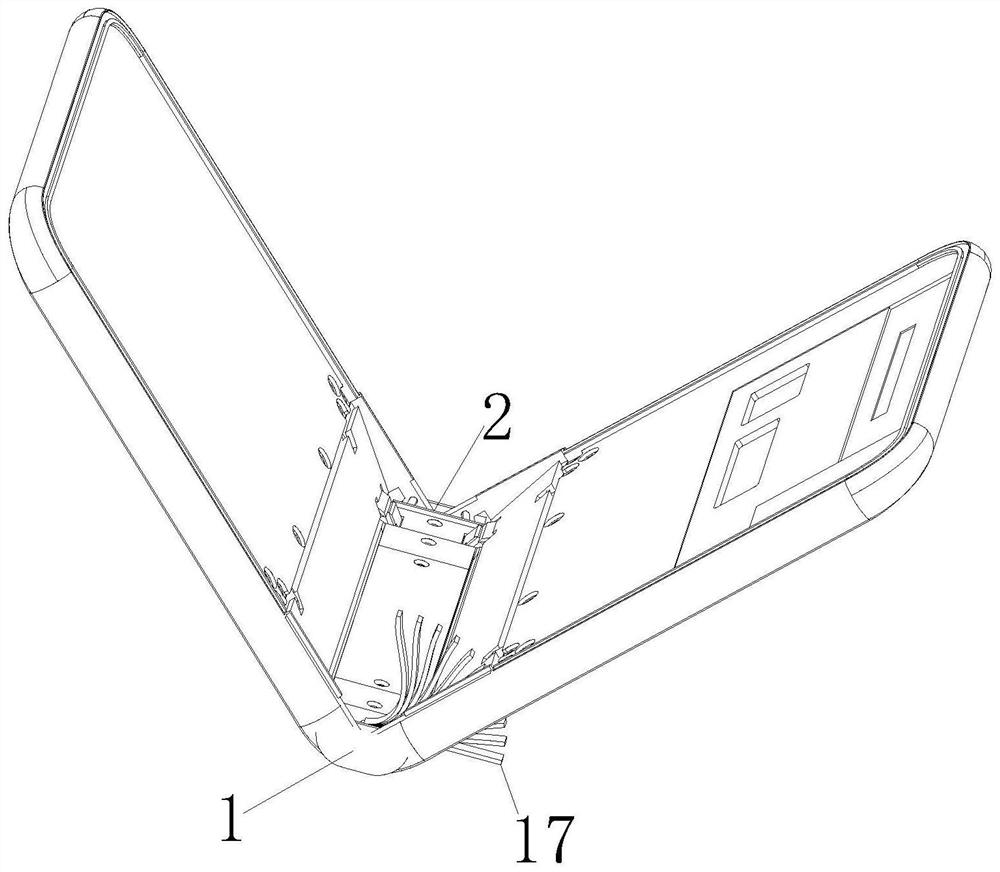

[0035] Such as Figure 1-18 As shown, the water drop-shaped inward-folding gear rotation mechanism with a variable center of circle disclosed in this embodiment includes a shaft cover 1 and a shaft 2 arranged at both ends of the shaft cover 1, and the shaft 2 includes two groups of main activities symmetrically distributed on both sides. Block 3, the main movable block 3 is combined and connected with a concave wheel connecting plate 4, a central movable block 5 and two groups of gear shafts 6 distributed side by side, two groups of side movable blocks 7, and two groups of cams 8, the main movable The block 3 is respectively provided with a flat chute 31, a transverse chute 32 and a semicircular arc groove 33, and a long track curved groove 34 is provided at the rear end of the flat chute 31, and a flat chute is provided at the end of the gear shaft 6. Position 61 and a bilaterally symmetrical positioning block 62, two sets of first connecting columns 51 and second connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com