Method for quickly and accurately adjusting the array plane attitude precision of multi-plate planar antenna

A planar antenna and adjustment method technology, which is applied to antenna arrays, devices for manufacturing antenna arrays, antennas, etc., can solve problems such as the inability to quantify the calculation of the adjustment amount, the inability to accurately locate the debugging position, the angle error between the prism and the reference plane, etc., and achieve debugging. The measurement algorithm is simple and clear, the test accuracy and accuracy are high, and the effect of precise positioning and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

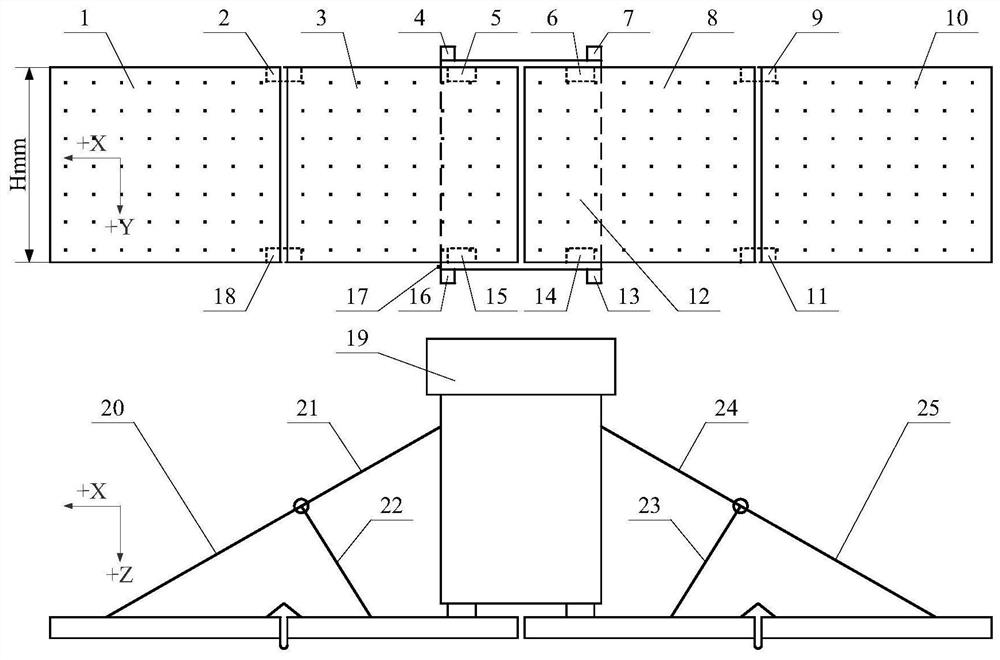

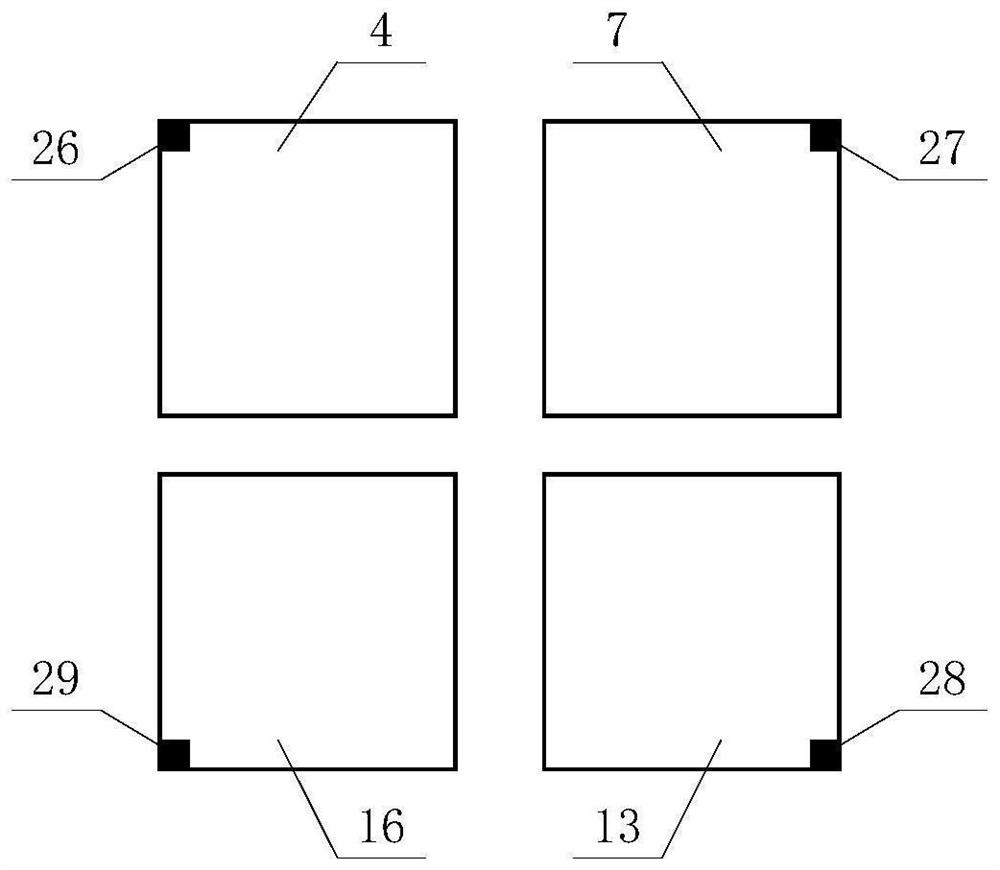

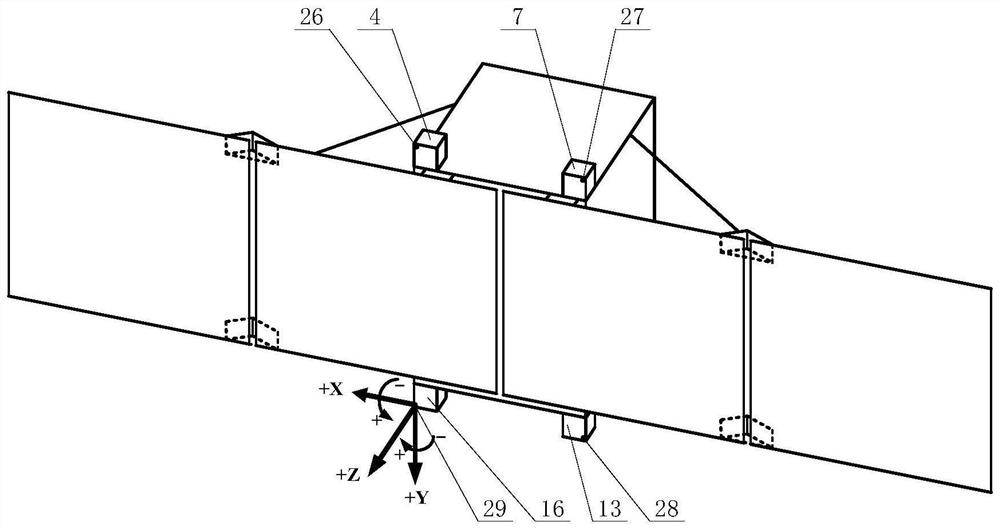

[0024] The following will combine Figure 1 ~ Figure 4 The method for quickly and accurately adjusting the attitude accuracy of the multi-board planar antenna array of the present invention will be further described in detail.

[0025] figure 1 Shown is a schematic structural diagram of a multi-plate planar antenna in a preferred embodiment of the present invention. see figure 1 , in this embodiment, the multi-board planar antenna includes four boards, which are +X side outer antenna board 1, +X side inner antenna board 3, -X side inner antenna board 8 and -X side outer antenna board 10, four boards The plane where the board is unfolded (that is, the antenna plane) is the XY plane, and the normal of the antenna plane points to the front of the array as the positive direction of the Z axis. The +X side outer antenna plate 1 and the +X side inner antenna plate 3 are hinged through the first +X side outer antenna plate installation hinge 2 and the second +X side outer antenna ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com