QFP packaging chip welding method

A soldering method and a chip-mounting technology are applied to the assembly of printed circuits with electrical components, electrical components, and printed circuit manufacturing. Soldering rate, the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

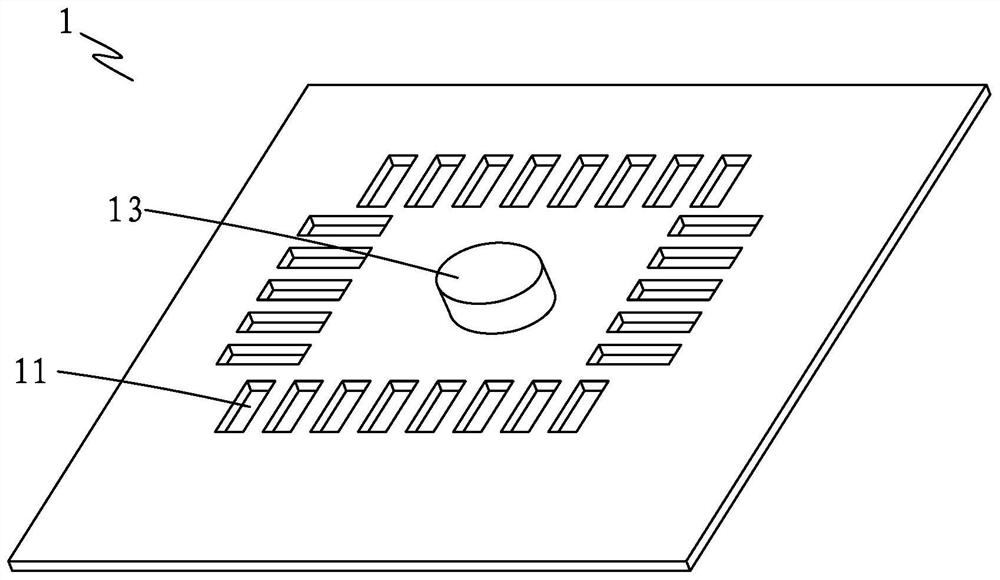

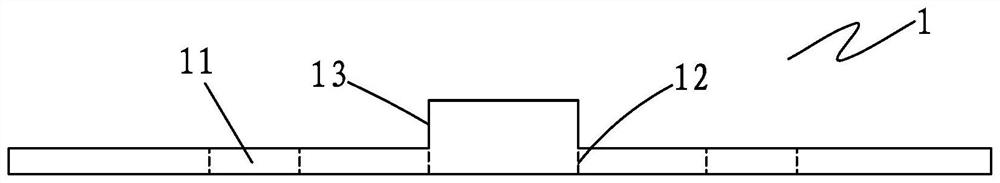

[0022] The general idea of the technical solution in the embodiment of the present application is as follows: the welded steel mesh 1 is set in a stepped shape, that is, outside the second through hole 12 corresponding to the ground pad 21, an extension part 13 is arranged upwardly, and the extension part 13 The height is half of the height difference between the pin 22 of the QFP package chip 2 and the ground pad 21, and the distance between the solder paste and the ground pad 21 is shortened to half of the original, so that the solder paste can better absorb the ground pad when heated 21 Complete welding.

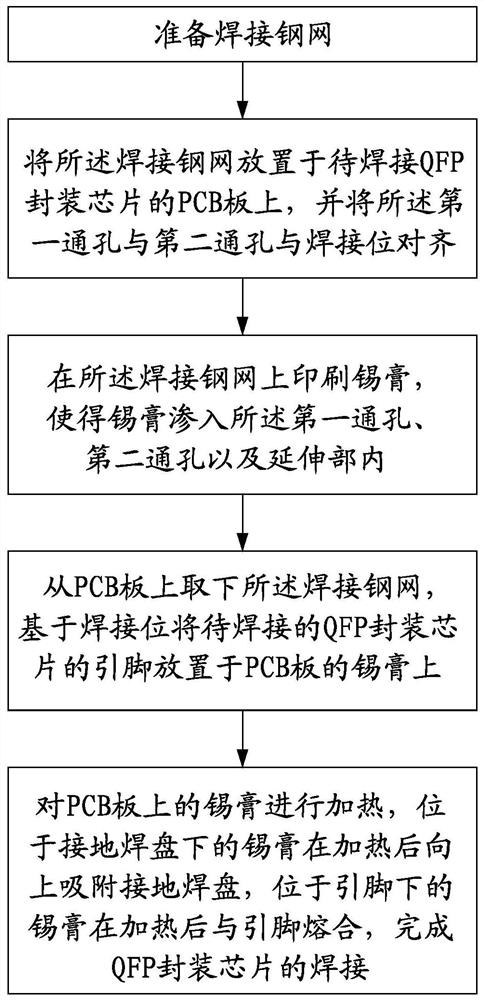

[0023] Please refer to Figure 1 to Figure 3 Shown, the preferred embodiment of a kind of QFP packaging chip welding method of the present invention, comprises the following steps:

[0024] Prepare the welded steel mesh 1; the welded steel mesh 1 is provided with several first through holes 11 and a second through hole 12; the position of the first through hole 11 corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com