A special flux for solar automatic welding

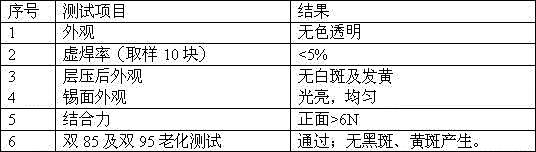

A technology of flux and solar modules, applied in the direction of welding medium, welding equipment, welding/cutting medium/materials, etc., can solve the problems of increasing manufacturing costs, etc., and achieve low false soldering rate, no white spots and yellowing, and smooth tin surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A special flux for solar automatic welding, which is prepared by mixing the following raw materials in weight percentage: 0.2% modified rosin resin, 1.6% combination of succinic acid, glutaric acid, adipic acid, citric acid and oxalic acid , Perfluorinated surfactant 0.1%, the balance is absolute ethanol.

Embodiment 2

[0019] A special flux for solar automatic welding, which is prepared by mixing the following raw materials in weight percentage: modified rosin resin 0.1%, a combination of glutaric acid, adipic acid and oxalic acid 1.8%, fluorocarbon surfactant 0.1% %, and the balance is isopropanol.

Embodiment 3

[0021] A special flux for solar automatic welding, which is prepared by mixing the following raw materials in weight percentage: 0.2% modified rosin resin, 2.0% combination of succinic acid and citric acid, 0.1% fluorocarbon surfactant, and The amount is absolute ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com