a pcb

A board body and locking ring technology, which is applied in the direction of electrical connection of printed components, printed circuit components, printed circuits, etc., can solve problems such as virtual soldering, and achieve low soldering rate, sufficient solder connection, and solid pad welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

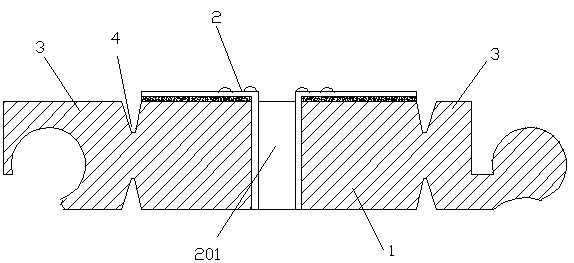

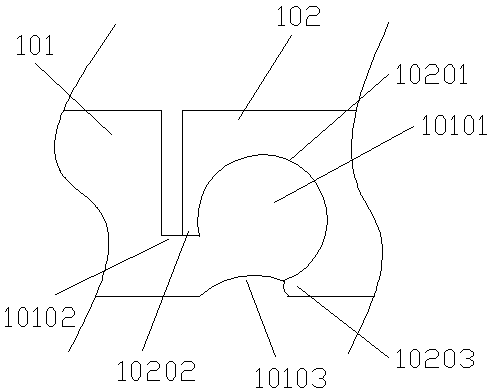

[0022] Such as figure 1 , figure 2 As shown, the embodiment of the present invention includes a board body 1, on which the board body 1 is provided with a tin-lock pad 2 for fixing tin, and the edge of the board body 1 is provided with a unilaterally rotating process edge 3; 1 is provided with a narrow edge portion 4 that is convenient for manual separation.

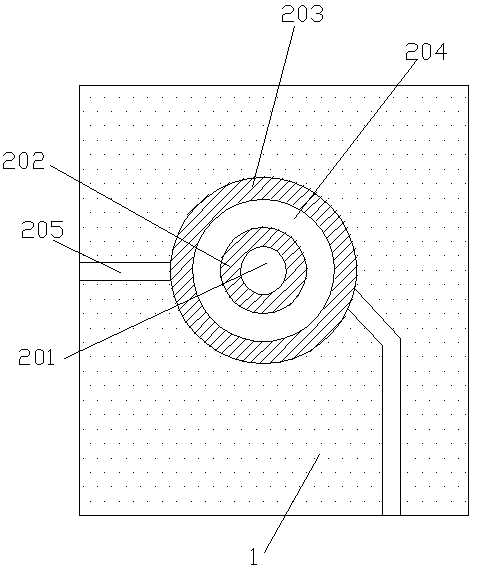

[0023] Such as figure 1 , image 3 As shown, the tin locking pad 2 of the embodiment of the present invention includes a through hole 201 for passing through the component pins, and a first locking ring for preventing the solder penetrating through the through hole 201 from reflowing back into the through hole 201 during wave soldering. 202, the second lock ring 203 used to prevent solder from overflowing to the surface of the board body 1, used to prevent the pad from detaching from the conductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com