Rice magnetic separation processing method

A processing method and rice technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of rice falling, poor removal of iron impurities in rice, and inability to absorb rice iron filings. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

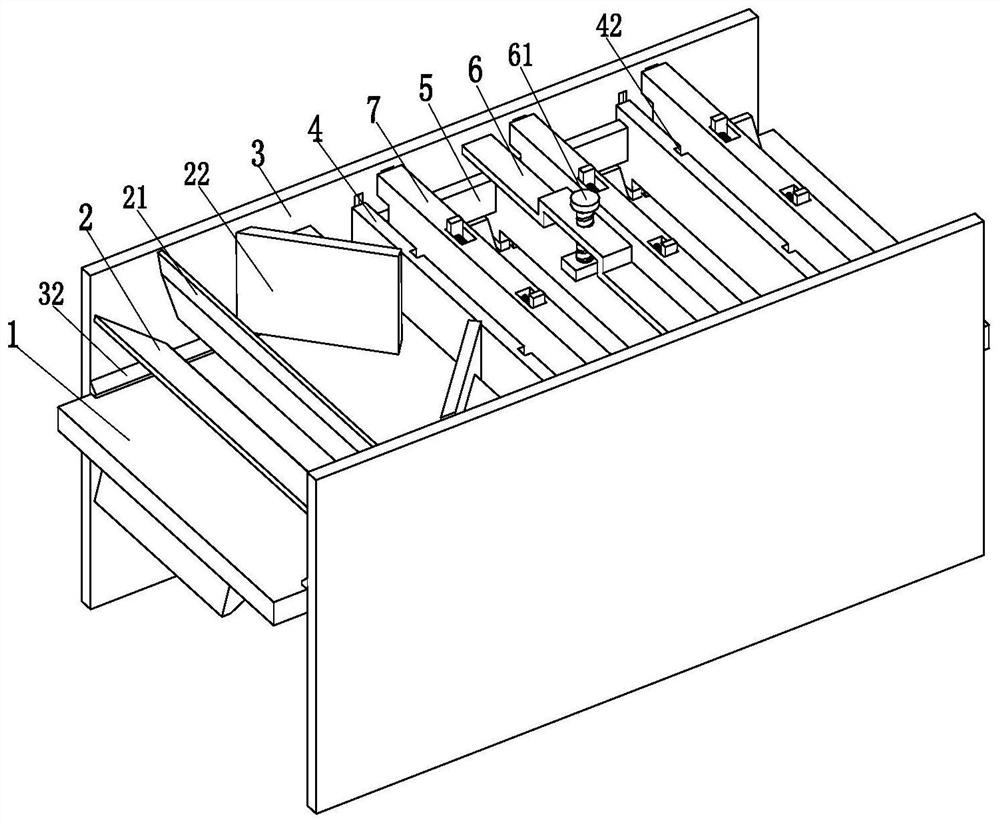

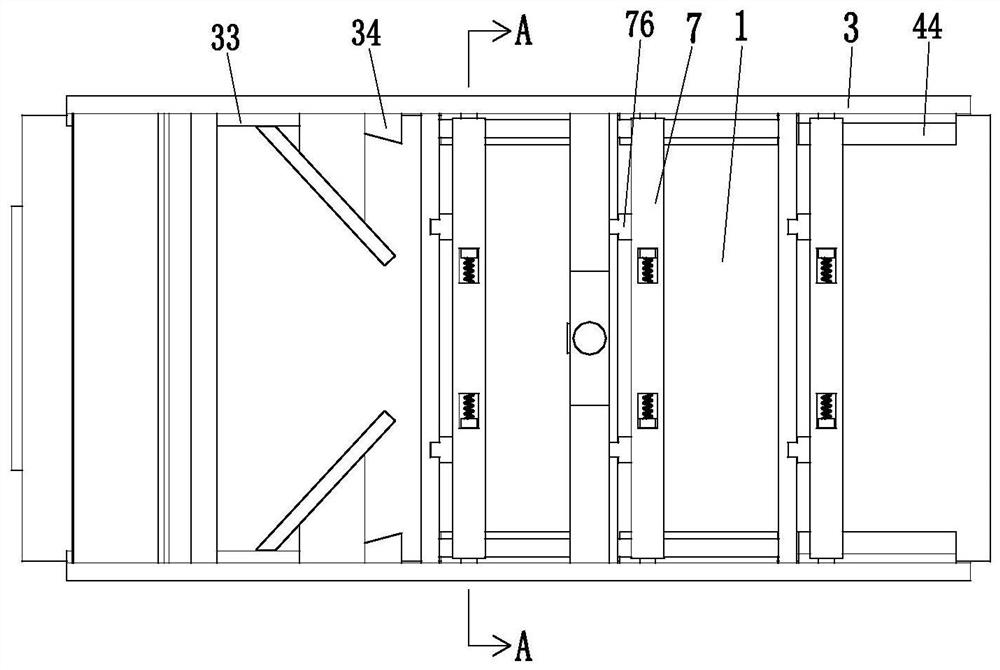

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

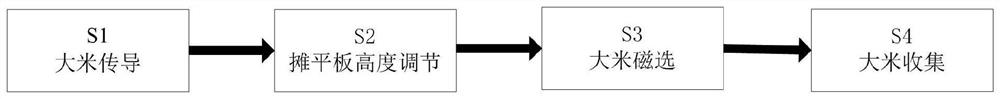

[0038] Such as Figure 1 to Figure 7 As shown, a rice magnetic separation processing method, the rice magnetic separation processing method adopts the following rice debris rapid cleaning device, the rice debris rapid cleaning device includes a conveyor belt 1, a conductive plate 2, a side guard plate 3, a spreader plate 4, and a linkage Plate 5, adjustment bracket 6 and suction mechanism 7, a side guard 3 is distributed on the front and rear sides of the conveyor belt 1, the conveyor belt 1 is installed on the external base through the transmission roller, and the lower end of the side guard 3 is connected to the external On the base, a conduction plate 2 is arranged between the left ends of the side guards 3, a spreading plate 4 is evenly arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com