Picking equipment for high-strength motorcycle steel backing based on contact surface barb mechanism

A high-strength, motorcycle technology, used in metal processing equipment, metal processing machinery parts, clamping and other directions, can solve problems such as low production efficiency, uneven steel back barbs, and no solution to steel back fixing, etc., to improve efficiency. , Improve the stability, prevent the effect of steel back dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

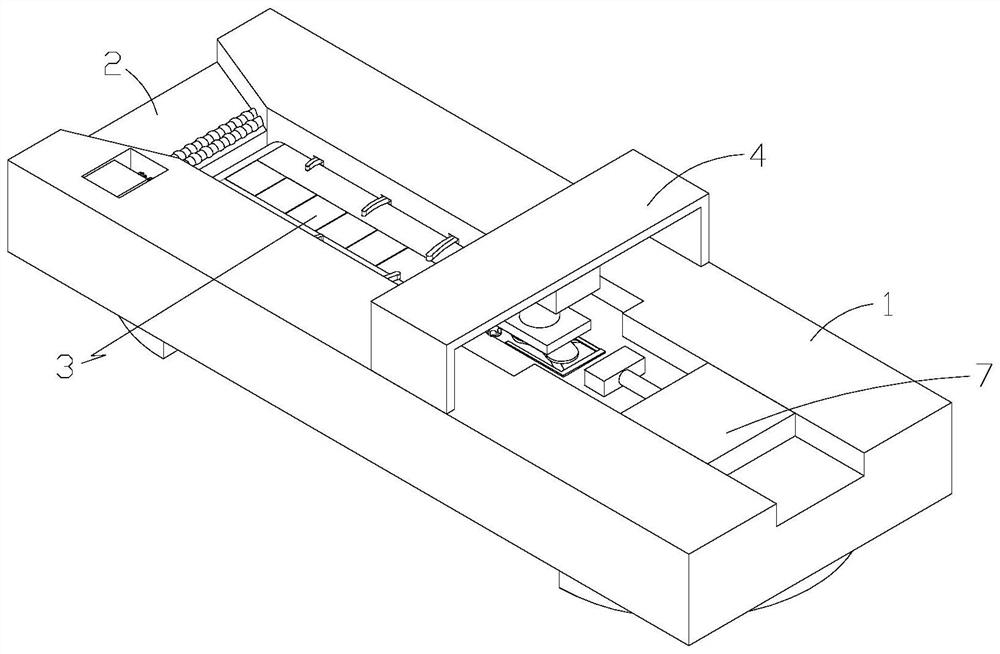

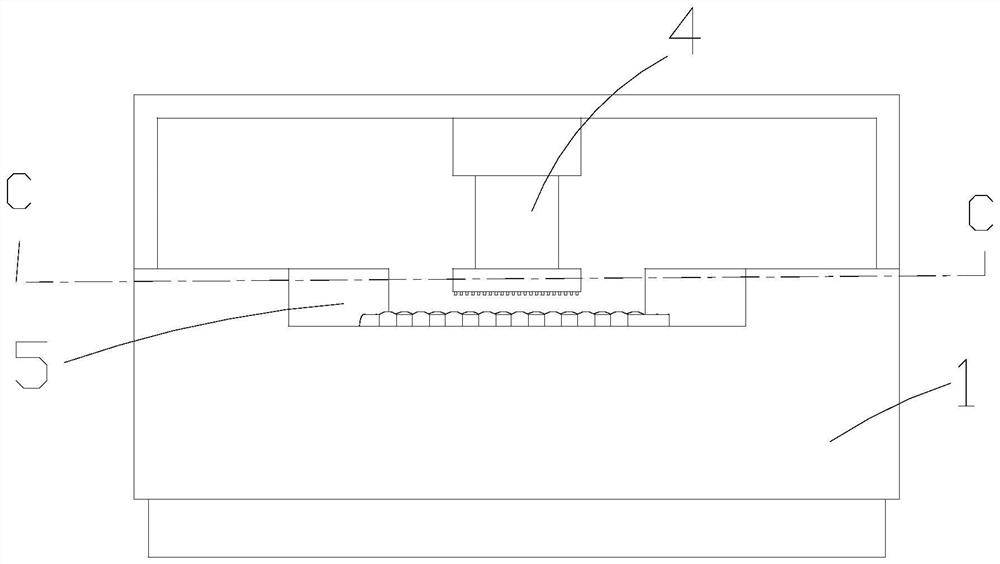

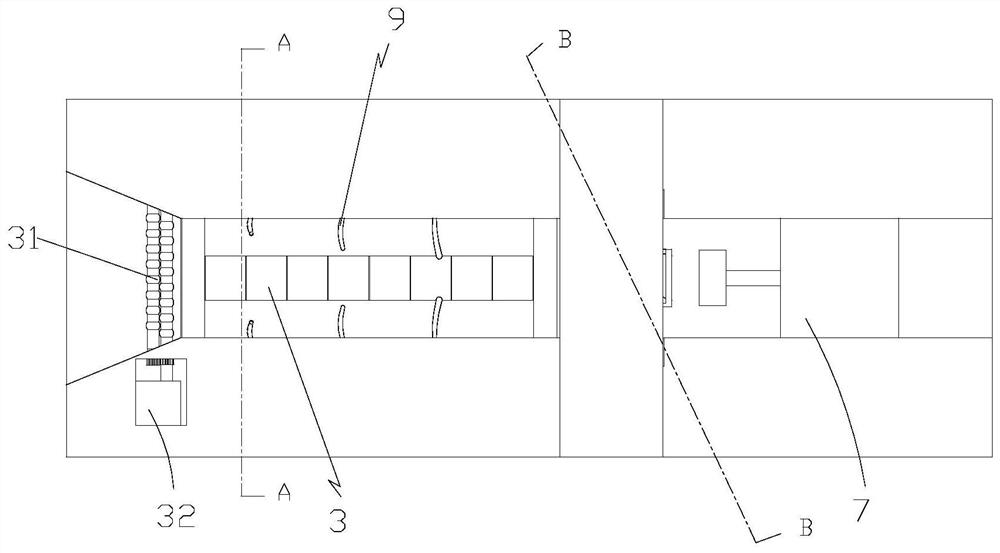

[0032] Such as Figure 1-12 As shown, a kind of stabbing equipment based on the contact surface barb mechanism of high-strength motorcycle steel back includes a housing 1, a feed port 2, a transmission device 3, a barb machine 4, a workbench 5, a clamping device 6, an unloading The material claw 7; the clamping device 6 shown includes a guiding mechanism 61, a limit block 62, a first spring 65, an adsorption disc 63, and a clamping mechanism 64; the feeding port 2 is located at the left end of the housing 1, The cross section of the feeding port 2 is trapezoidal; the conveying device 3 is arranged in the described feeding port 2; the barb machine 4 is arranged on the housing 1, and the barb machine 4 is directly purchased Obtain; the workbench 5 is located on the lower side of the barb machine 4 and is located on the housing 1; the clamping device 6 is located on the workbench 5; the discharge claw 7 is located on the The right side of the workbench; the guide mechanism 61 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com