Loading device for bearing processing

A bearing processing and rotating shaft technology, which is applied in the direction of metal processing equipment, manufacturing tools, workpiece feed movement control, etc., can solve problems such as low efficiency and troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

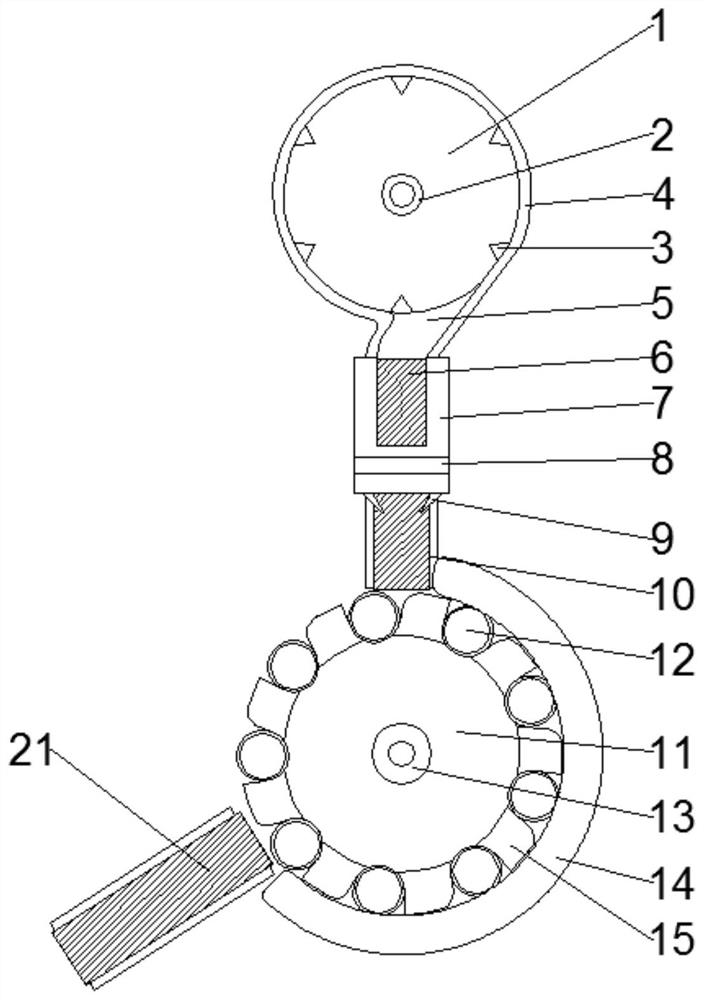

[0020] Example: such as Figure 1-3 As shown, the present invention is a bearing processing and feeding device, comprising.

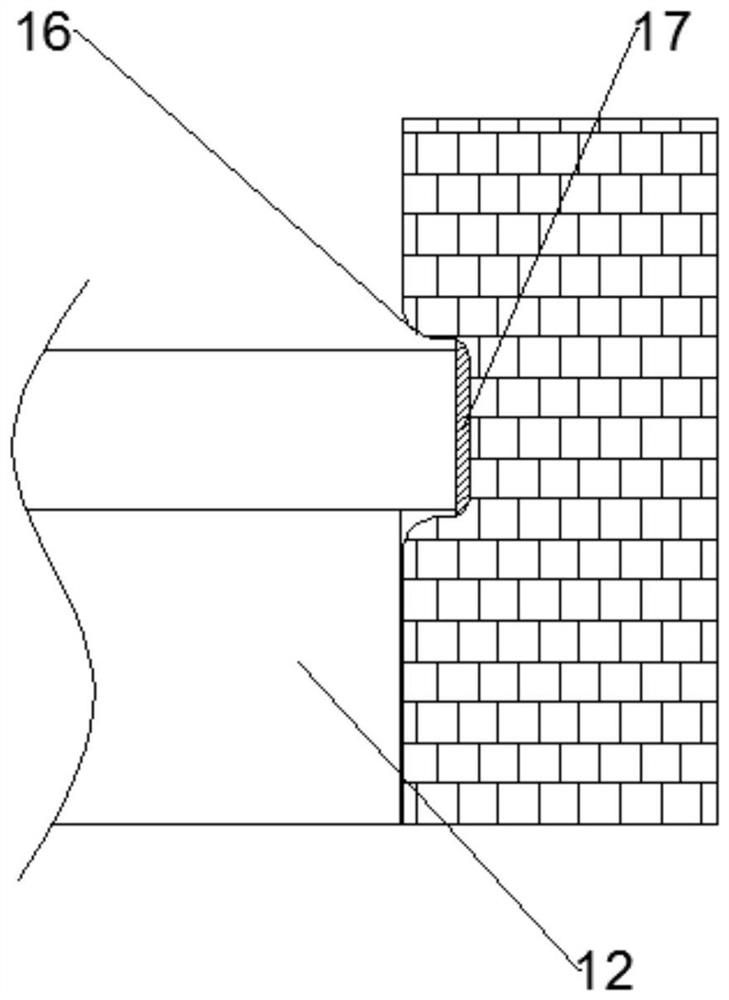

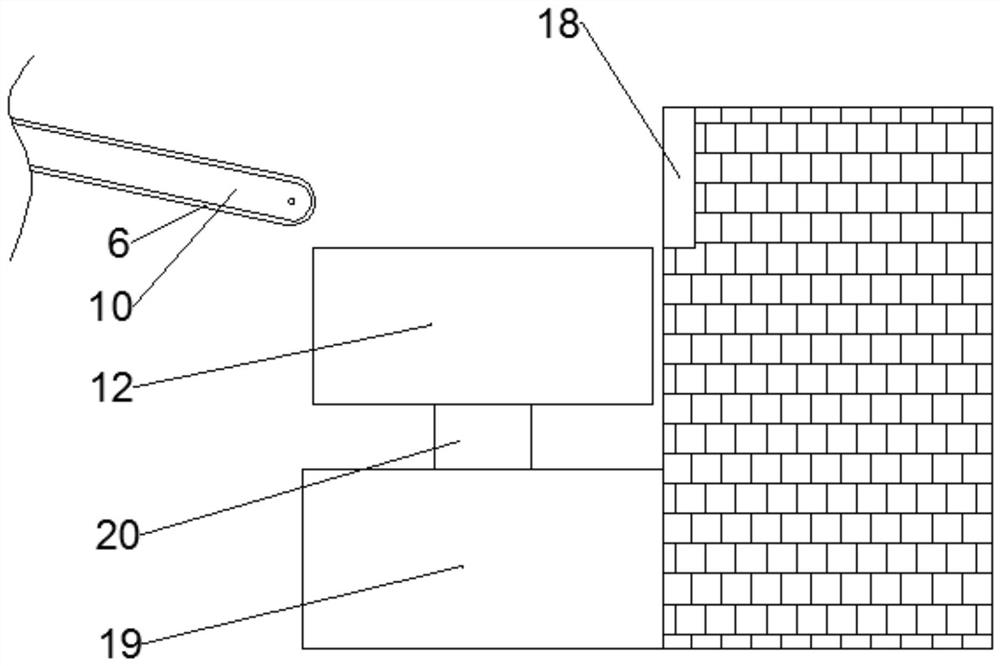

[0021] Wherein, it includes a feeding disc 1, a conveying plate 10 and a processing disc 11. The center of the feeding disc 1 is fixedly equipped with a first rotating shaft 2, and the surrounding of the feeding disc 2 is surrounded by a fixed ring 4. A fixed block 3 is fixedly installed, a discharge port 5 is arranged under the fixed ring 4, a conveyor belt 6 is wrapped around the conveying plate 10, a fixing frame 7 is fixedly installed on both sides of the conveying plate 10, and a second rotating shaft is fixedly installed in the center of the processing disc 11 13. A trapezoidal fixed block 15 is fixedly installed around the processing disc 11. A lifting motor 19 is fixedly installed around the processing disc 11. A lifting rod 20 is fixedly installed above the lifting rod 20. A support block 12 is fixedly installed above the lifting rod 20. Around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com