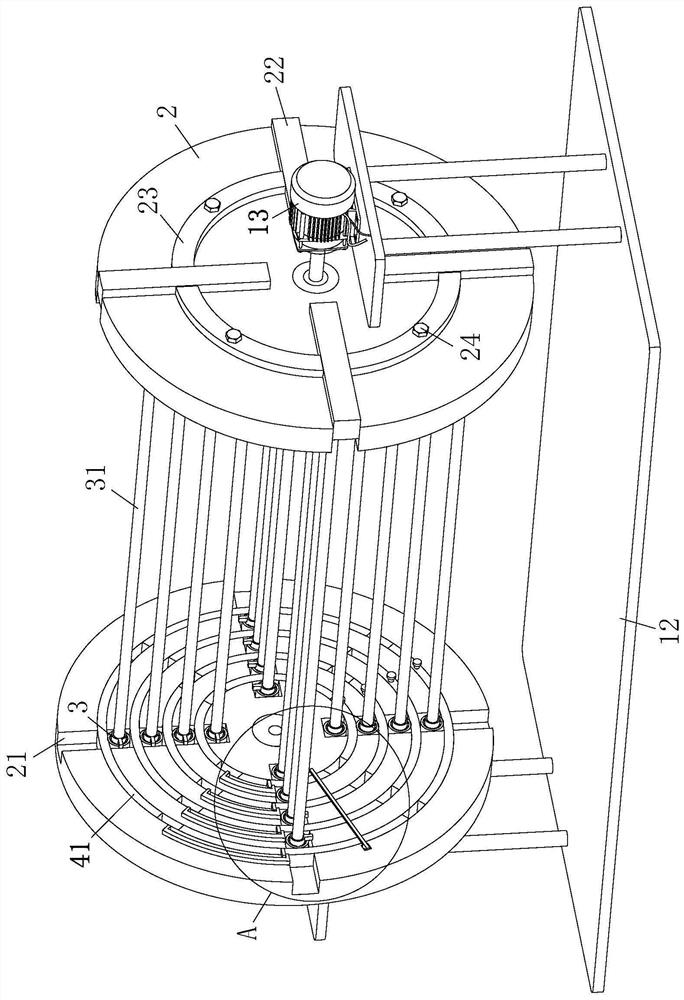

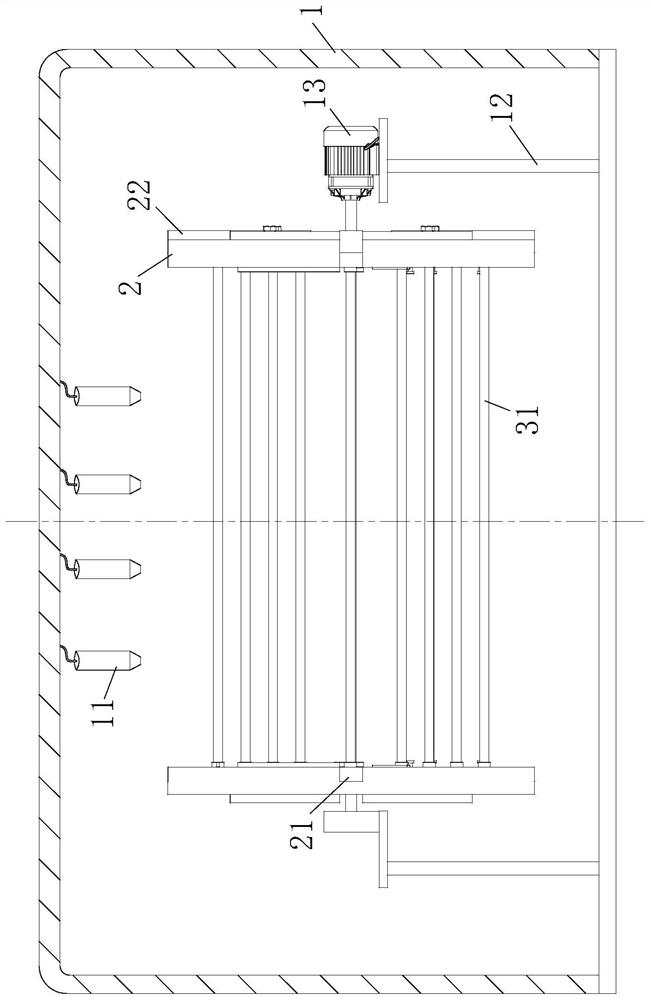

Pneumatic numerical control shot blasting machine

A shot peening machine, pneumatic technology, applied in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc. Processing speed and other issues to achieve the effect of improving the efficiency and quality of shot peening, improving the quality of shot peening, and reducing fragmentation and fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

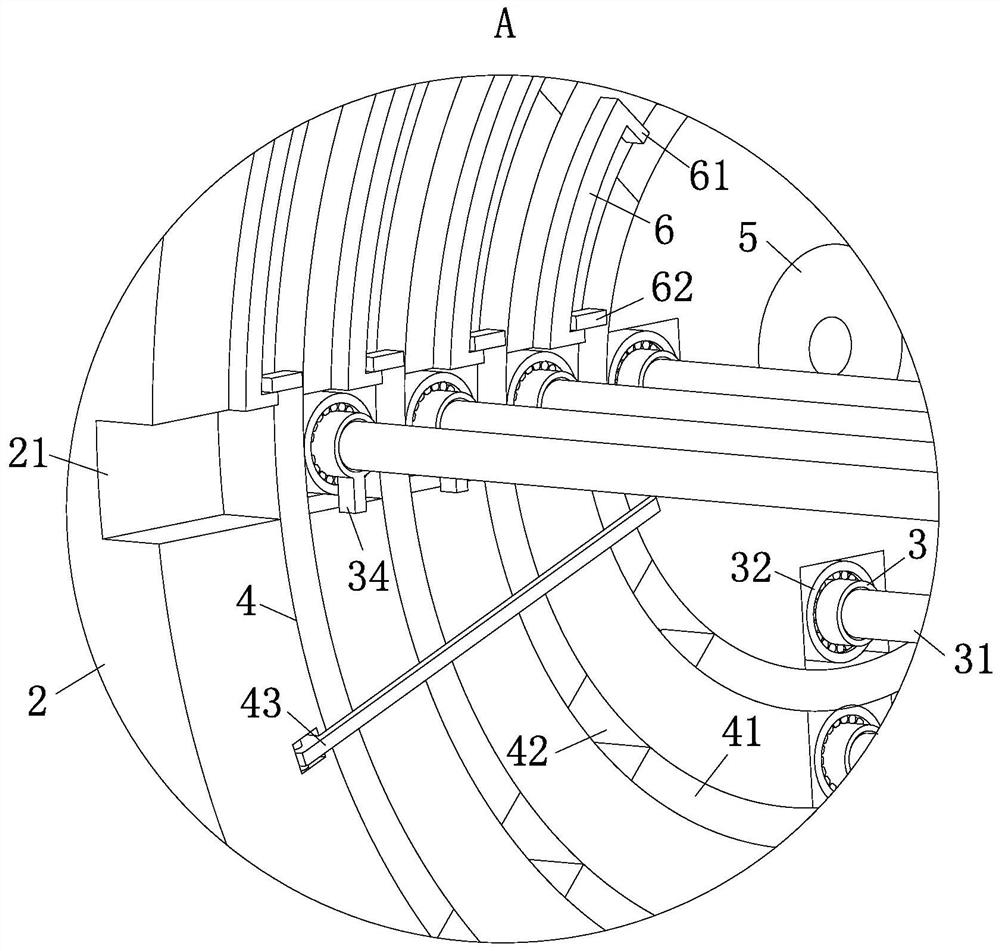

[0025] As an embodiment of the present invention, a group of annular grooves 4 are respectively provided on the end faces of the turntable 2 close to each other, and annular plates 41 with matching shapes are respectively connected to the inner portions of the annular grooves 4 . The outer end faces of 41 are respectively provided with communicating grooves 42 that can cooperate with the slots 21. During work, in order to make the workpiece 31 pre-installed between the two rotating disks 2 more conveniently and quickly, at this time, by setting the annular grooves 4 that cooperate with each other With the annular plate 41, when the workpiece 31 is inserted into the slot 21 between the two symmetrical turntables 2, the connecting grooves 42 on the end surface of the annular plate 41 are aligned with the slots 21 respectively through the rotation of the annular plate 41 inside the annular groove 4. When the workpiece 31 can slide through the connecting groove 42 in the slot 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com