Suspension system of rear-engine rear-drive electric automobile and installation method

A suspension system and electric vehicle technology, applied in the direction of electric power devices, control devices, power devices, etc., can solve the problems of high cost and difficult assembly, and achieve the effect of low cost, small assembly difficulty and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

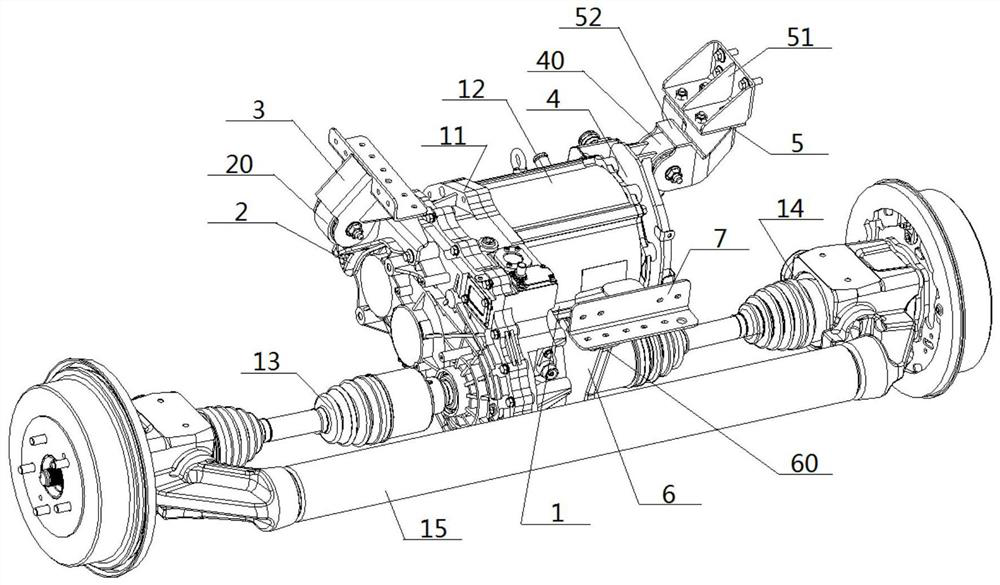

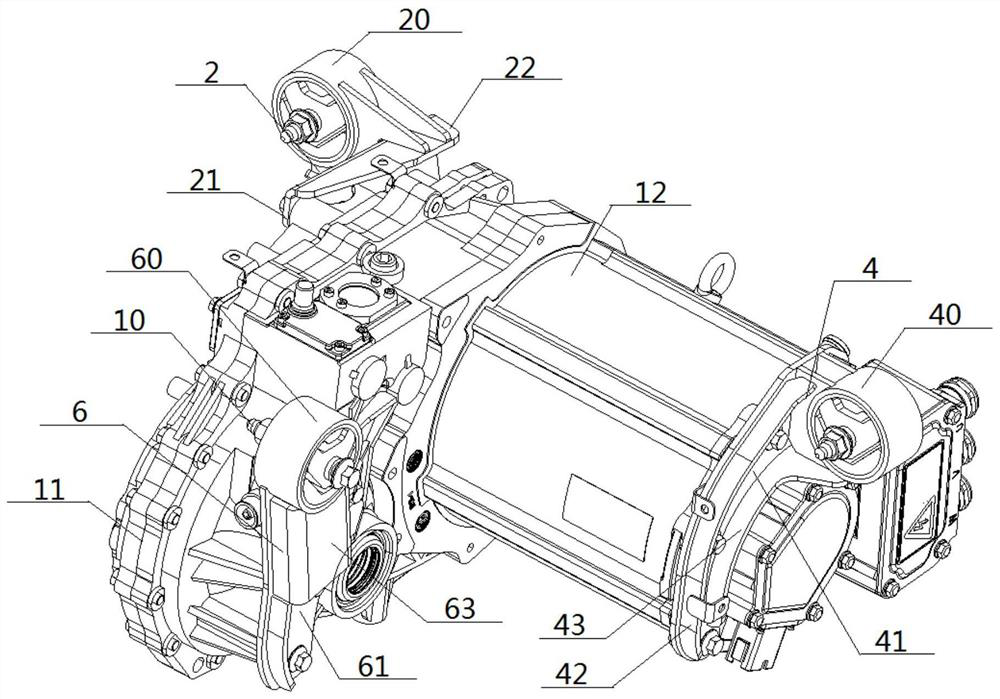

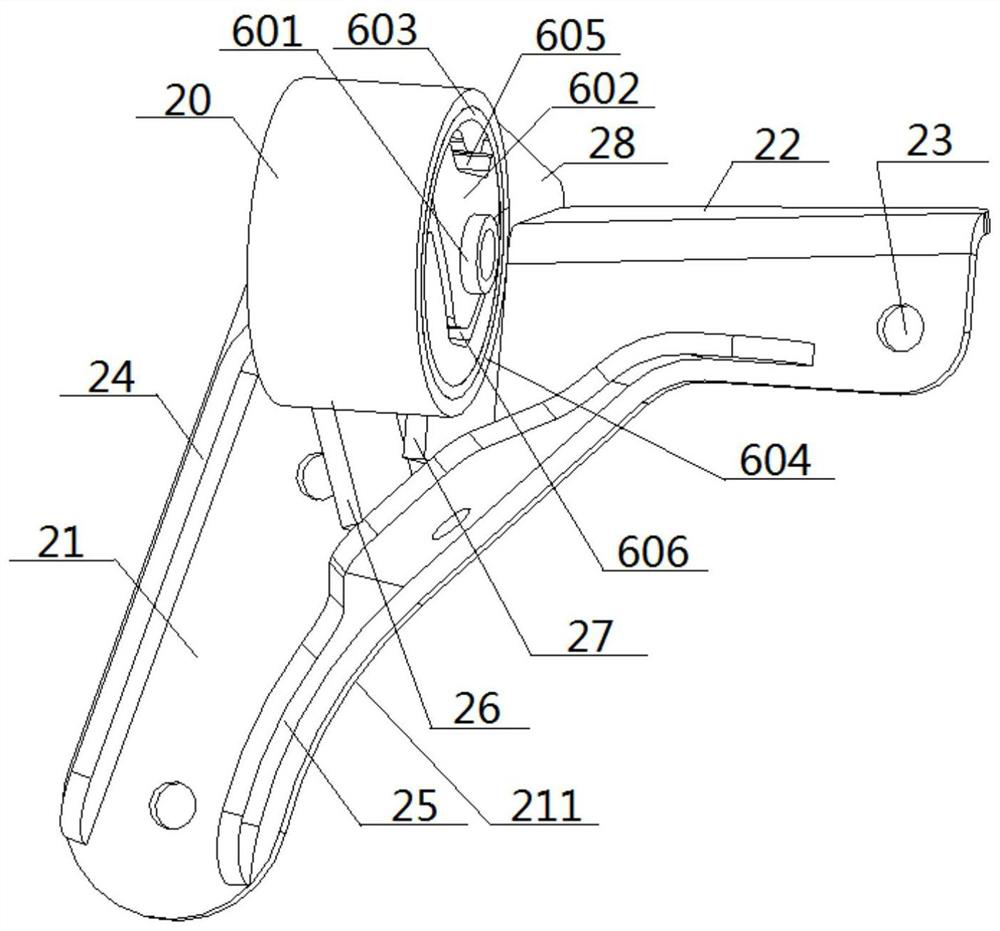

[0071] see figure 1 — Figure 15 , a rear-mounted rear-drive electric vehicle suspension system, comprising a reduction box 11 and a drive motor 12, the right side of the front end of the reduction box 11 is connected with the left end of the drive motor 12, and the rear end of the reduction box 11 on both sides They are respectively connected with the inner ends of the left drive shaft assembly 13 and the right drive shaft assembly 14; the left side of the front end of the reduction box 11 is connected with the left suspension 2, and the connection between the left suspension 2 and the reduction box 11 Opposite to the connection between the drive motor 12 and the reduction box 11, the right end of the drive motor 12 is connected to the right suspension 4, and the rear end of the reduction box 11 is close to the connection between the reduction box 11 and the right drive shaft assembly 14. The parts are connected with the rear suspension 6; the tops of the left suspension 2, ...

Embodiment 2

[0074] The basic content is the same as that of Example 1, except that:

[0075] On hardware:

[0076] The left connection unit 3 is a left connection bracket, the rear connection unit 7 is a rear connection bracket, and the right connection unit 5 includes a right connection bracket 51 and a right transition bracket 52 .

[0077] In the installation method:

[0078] The welding of the left connecting unit 3 and the rear connecting unit 7 to the vehicle frame 8 respectively refers to: welding the left connecting bracket and the rear connecting bracket to the vehicle frame 8 respectively. The bolt connection between the right connecting unit 5 and the frame 8 refers to: bolting the right connecting bracket 51 and the frame 8, tightening the bolts, and then connecting the right transition bracket 52 and the right connecting bracket 51 with bolts without tightening the bolts. .

Embodiment 3

[0080] The basic content is the same as that of Example 1, except that:

[0081] See Figure 14 , the figure shows the pointed bolt 10 used in the bolt connection of the present invention. The pointed bolt 10 includes a nut 101, a screw segment 102, a thread segment 103, and a bolt head 104 connected in sequence. The side of the thread segment 103 An external thread is provided on the enclosure, the top end of the bolt head 104 is connected with the threaded section 103, the bottom end of the bolt head 104 extends outward, and the diameter of the bolt head 104 changes gradually from top to bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com