Projection welding structure of automobile body connecting reinforcer and process thereof

A technology for automobile body and welding structure, applied in welding equipment, metal processing equipment, motor vehicles, etc., can solve the problems of deformation of parts, reduced connection strength, long welding time, etc., to reduce production costs, shorten welding time, and reduce welding simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

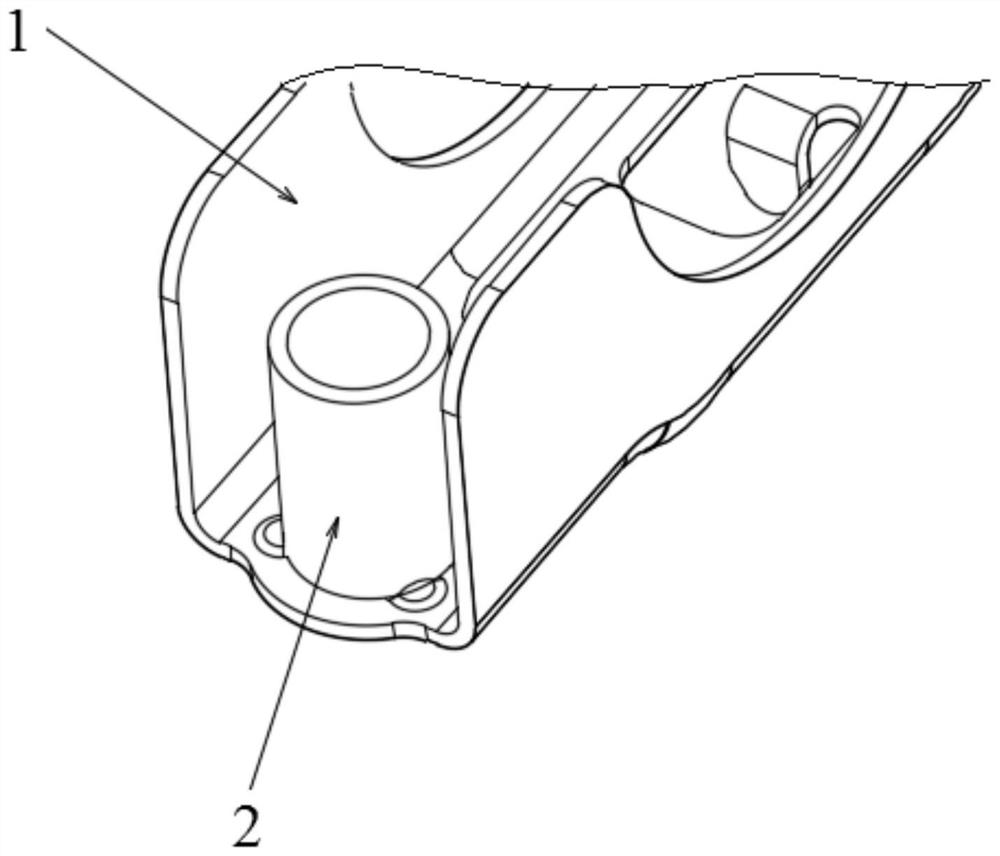

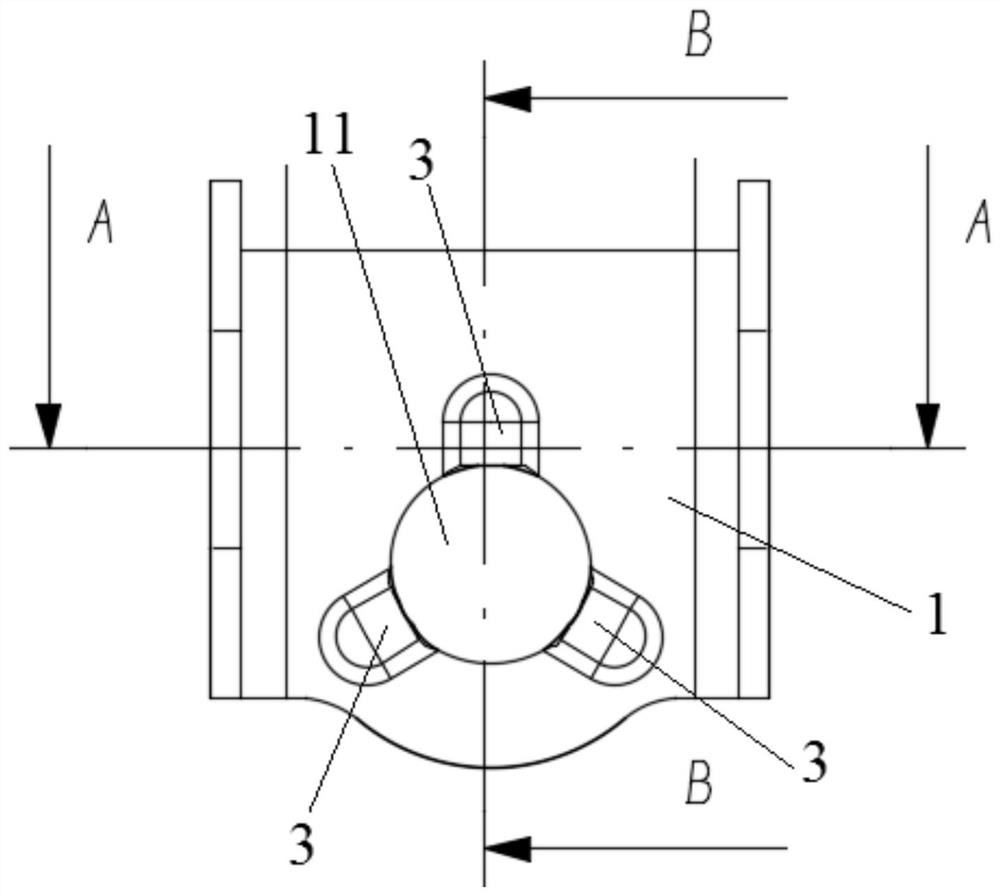

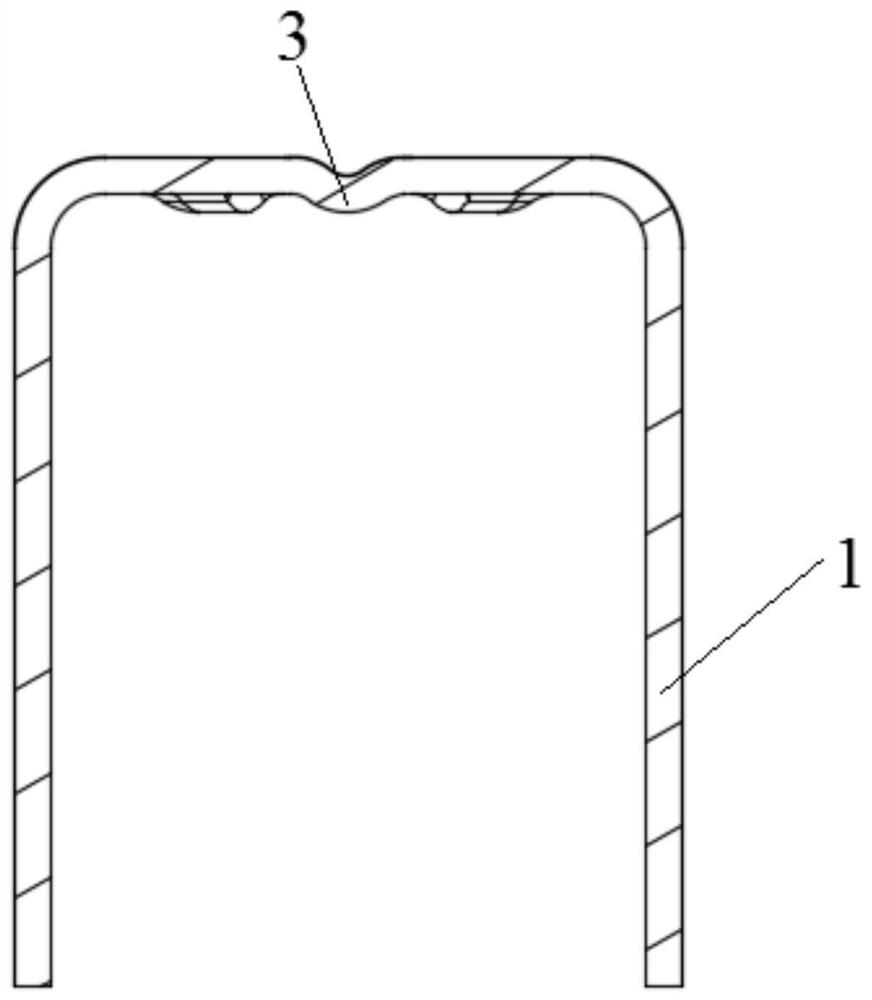

[0017] see Figure 1 to Figure 5 , an embodiment of the present invention, a projection welding structure for connecting reinforcing parts of automobile body, including a reinforcing tube 2 and a stamping part 1, the stamping part 1 is provided with a through hole 11; the stamping part 1 is provided with three convex hulls 3, And the three protrusions 3 are evenly distributed around the through hole 11 , and one side edge of each protrusion 3 coincides with the edge of the through hole 11 ; the bottom end of the reinforcing tube 2 is welded on the three protrusions 3 . Among the three convex hulls 3 , the angle between every two adjacent convex hulls is 120°.

[0018] The present invention also provides a projection welding welding process for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com