Method for preventing deformation of water-cooled wall assembly piece

A water-cooled wall and assembly technology, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of flue gas leakage, tight furnace seal, etc., reduce water-cooled wall bending, simple implementation method, Avoid complex environment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

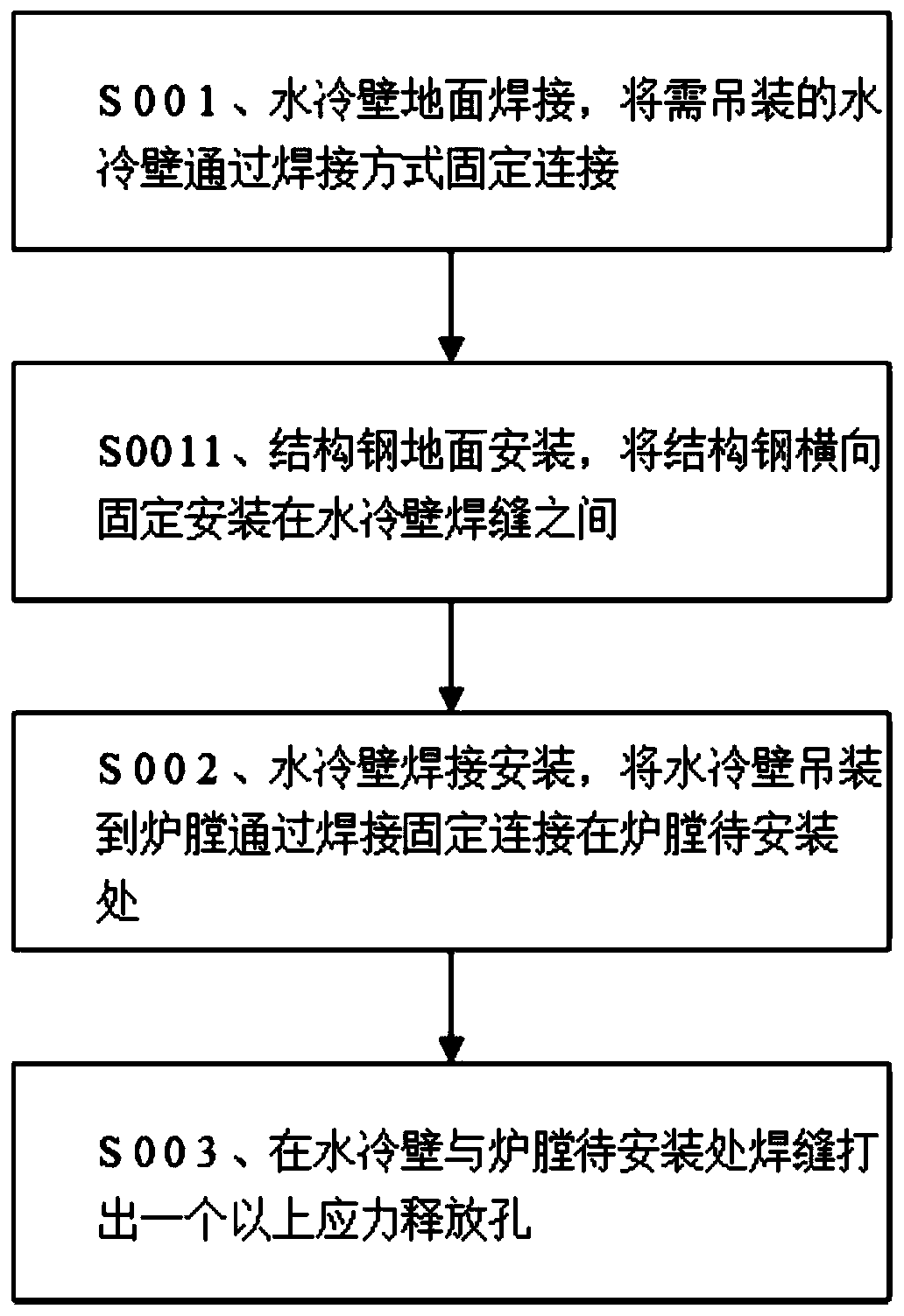

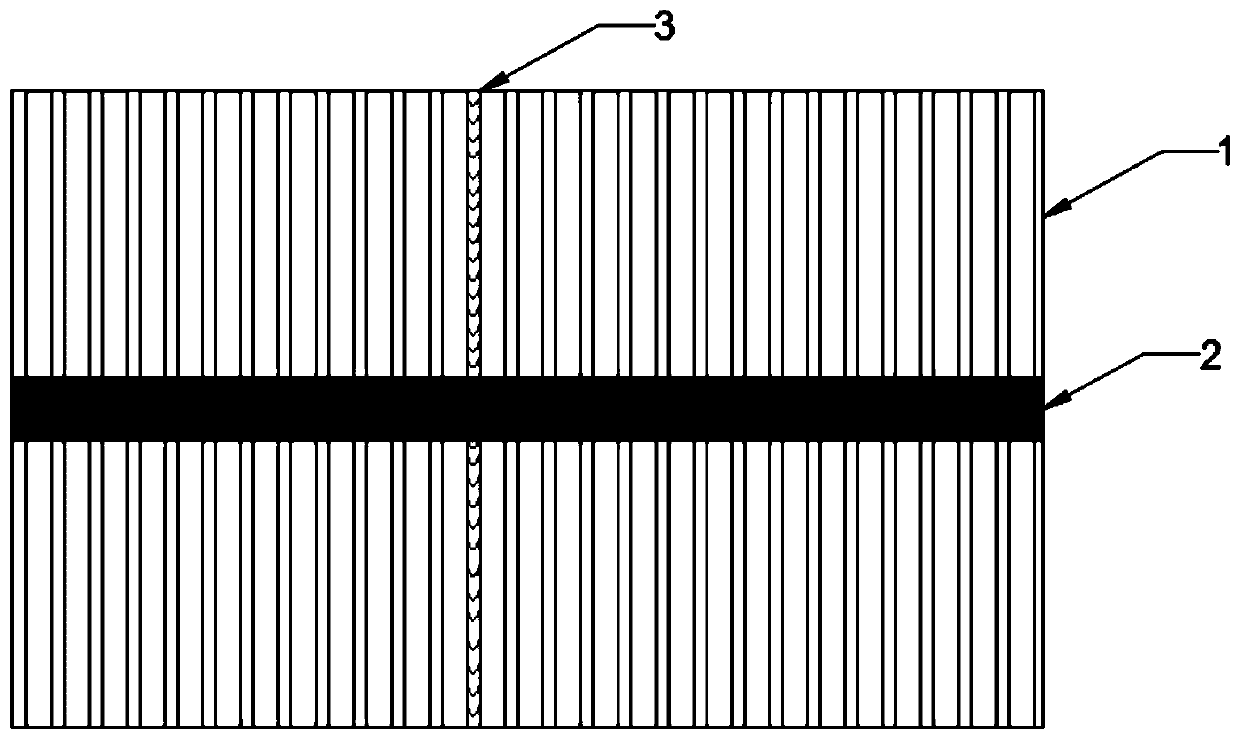

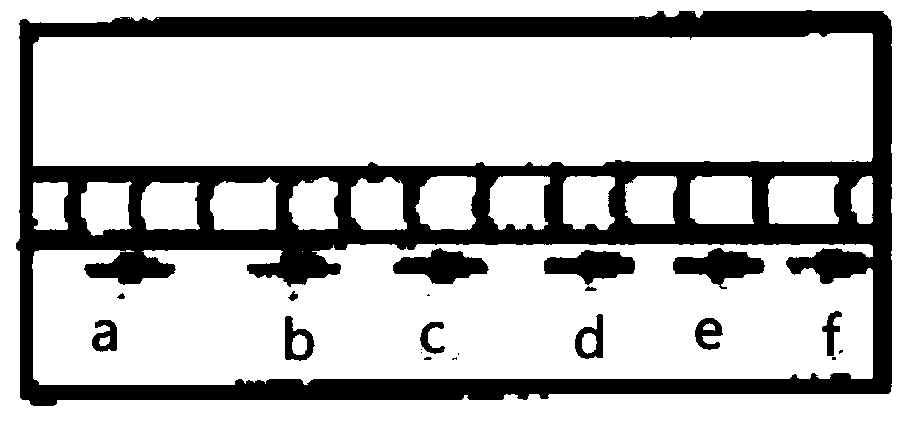

[0018] refer to figure 1 and image 3 , a method for preventing deformation of a water wall assembly, said method comprising the steps of,

[0019] S001. Weld the water-cooled wall on the ground, and fix and connect the water-cooled wall 1 to be hoisted by welding;

[0020] S002. Welding and installing the water-cooled wall, hoisting the water-cooled wall 1 to a high place and fixedly connecting it to the place to be installed by welding.

[0021] The present invention avoids the complex environment of high-altitude welding operation by first welding on the ground and then hoisting and installing, makes the welding simple and efficient, and avoids the bending of the weld seam between the water-cooled walls caused by the hoisting and welding of the water-cooled walls 1. The implementation method of the present invention is simple, and can greatly reduce the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com