Steam vulcanization process for power cable

A power cable and steam technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of waste of resources, sagging of cable conductors, affecting the positioning of cable conductors, etc., and achieve the effect of reducing the probability of sagging and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

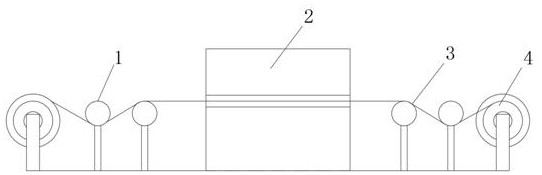

[0028] refer to Figure 1-5 , a power cable steam vulcanization process, the cable conductor is released, and enters the steam vulcanization device 2 through the first wire drawing device 1, and after the cable conductor completes steam vulcanization and cross-linking, it is guided and wound on the take-up wire through the second wire drawing device 3 4 rolls.

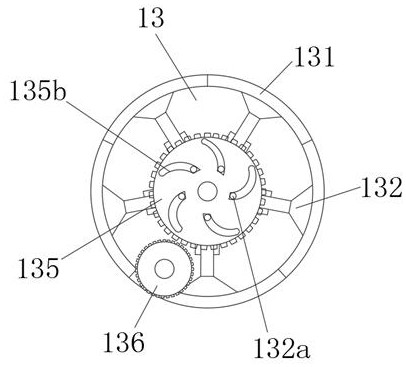

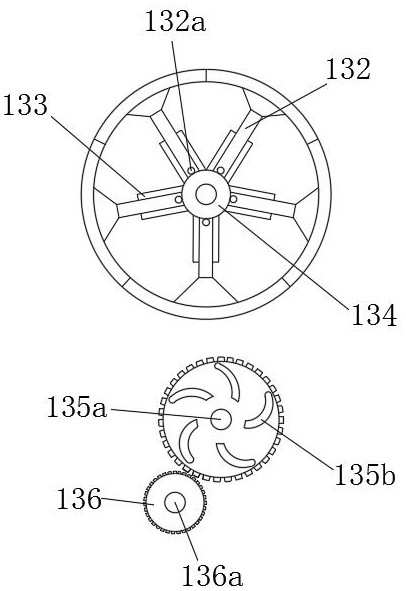

[0029] The first wire-drawing device 1 and the second wire-drawing device 2 are arranged symmetrically, each wire-drawing device includes two wire-drawing units, each of the wire-drawing units includes a first mounting plate 11, and one side of the first mounting plate 1 A second mounting plate 12 is provided, and a retractable adjustment unit 13 is arranged between the first mounting plate 11 and the second mounting plate 12, and the first mounting plate 11 and the second mounting plate 12 The bottom end is fixedly connected to the support plate 14 , and the bottom surfaces of the two support plates 14 corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com