Preparation method of red, green and blue three-primary-color orthogonal up-conversion fluorescent safe ink

A technology of three primary colors, red, green and blue, applied in chemical instruments and methods, inks, luminescent materials, etc., can solve the problems of unsatisfactory information protection, lack of effective protection of anti-counterfeiting patterns, and easy to be copied, so as to avoid background fluorescence interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

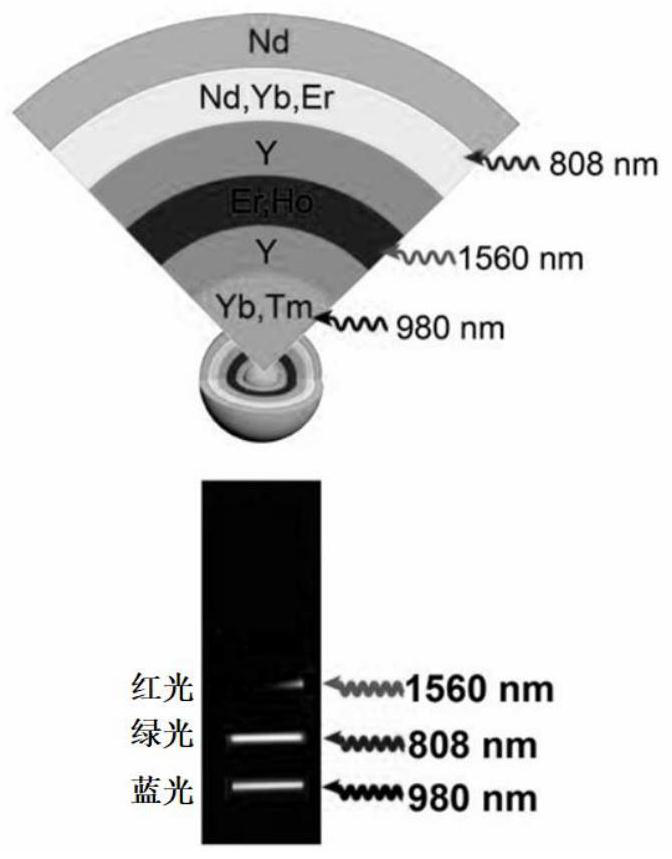

[0029] The preparation method of trichromatic orthogonal luminescent five-layer core-shell structure nanoparticles, the specific steps are as follows:

[0030] (1)NaYF 4 : Synthesis of Yb / Tm core nanoparticles. Take a 50mL two-necked round-bottomed flask as a reaction vessel, and a total amount of 0.4mmol of Y(CH 3 COO) 3 (69.5%), Yb(CH 3 COO) 3 (30%) and Tm(CH 3 COO) 3 (0.5%) aqueous solution was added with 3 mL of oleic acid and 7 mL of octadecene, and the resulting mixture was stirred at 150° C. for 60 minutes to remove water and low-boiling solvent molecules to form an oleic acid complex precursor. After cooling the resulting mixture to room temperature, 4 mL of NH 4 F (0.4moL / L) and 2mL NaOH (0.5moL / L) in methanol solution, heated to 50°C and continuously stirred for 30 minutes, then heated to 100°C and kept under vacuum for 10 minutes to remove methanol, then inert gas Under protection, the temperature was raised to 290° C. for 90 minutes. After the reaction was...

Embodiment 2

[0036] Example 2: Preparation of hydrophilic trichromatic orthogonal luminescent five-layer core-shell nanoparticle.

[0037] Disperse the trichromatic orthogonal luminescent nanoparticles wrapped by oleic acid into a mixed solution of 1ml ethanol and 1ml hydrochloric acid (2M), and then centrifuge at a speed of 16000r / min for 20min to remove the oleic acid ligands on the surface of the nanoparticles to obtain The ligand-free nanoparticles on the surface were washed twice with ethanol and finally redispersed in deionized water.

Embodiment 3

[0038] Embodiment 3: Preparation of acid-base indicator thymolphthalein solution. Weigh 0.1 g of thymolphthalein, dissolve it in 100 ml of ethanol with a volume fraction of 90%, and wait until it is completely dissolved by ultrasonication.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com