Preparation of laser excitation rare earth doped calcium silicon-phosphate high-brightness three-primary-color nano phosphor powder as well as product and application thereof

A nano-fluorescent powder and rare earth doping technology, which is applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of low preparation purity and few types of laser-excited white light LD phosphors, etc., and achieve simple process and structure The effect of easy control and high powder purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

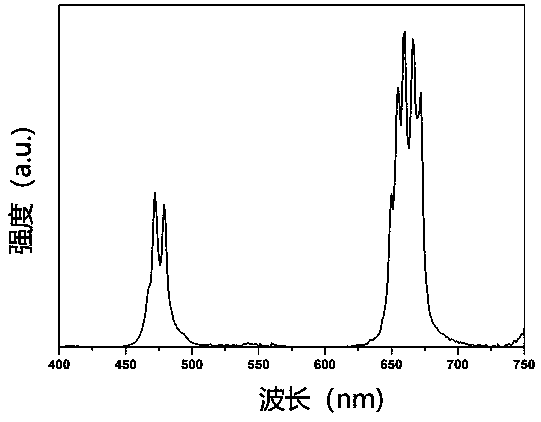

[0023] Weigh calcium oxide: calcium phosphate: tetraethyl orthosilicate in a molar ratio of 0.5mol:0.2mol:0.1mol to weigh the powder, then weigh 0.02mol of erbium nitrate and dissolve it in deionized water, stir and add 0.001mol of citric acid Stir for 30 minutes and move to an electric furnace until the liquid burns. After burning, the powder is ground and loaded into an alumina boat and placed in a muffle furnace. Oxygen is introduced to raise the temperature to 600°C for 100 minutes, keep it warm for 8 hours, and then cool down to room temperature. Calcined, ball milled and granulated to obtain rare earth doped silicon calcium phosphate phosphor. Luminescent properties were tested using a Flog-3 fluorescence spectrometer. Under 980nm laser excitation, there is an obvious luminescence peak in red light.

Embodiment 2

[0025] Weigh strontium nitrate: calcium phosphate: tetraethyl orthosilicate ratio 0.5mol:0.2mol:0.1mol to weigh the powder, then weigh 0.001mol of samarium nitrate and 0.0025mol of ytterbium nitrate, dissolve them in deionized water and add 0.025mol of Stir the citric acid for 30 minutes and move it to an electric heating furnace until the liquid burns. After the combustion, the powder is ground and loaded into an alumina boat and put into a muffle furnace. The temperature is raised to 1000°C after passing in argon for 100 minutes, kept for 2 hours, and then lowered to room temperature. Calcined, ball milled and granulated to obtain rare earth doped silicon calcium phosphate phosphor. Luminescent properties were tested using a Flog-3 fluorescence spectrometer. Under 980nm laser excitation, there is an obvious luminescence peak in blue light.

Embodiment 3

[0027] Weigh barium chloride: calcium phosphate: tetraethyl orthosilicate ratio 0.5mol:0.2mol:0.1mol to weigh the powder, then weigh 0.01mol of thulium nitrate and 0.005mol of ytterbium nitrate, dissolve in deionized water and stir to add 0.005mol The citric acid was stirred for 30 minutes and moved to the electric furnace until the liquid was burned. After the combustion, the powder was ground and loaded into an alumina boat and placed in a muffle furnace. Air was introduced to raise the temperature to 800°C for 100 minutes, kept for 5 hours, and then dropped to room temperature. Calcined, ball milled and granulated to obtain rare earth doped silicon calcium phosphate phosphor. Luminescent properties were tested using a Flog-3 fluorescence spectrometer. Under 980nm laser excitation, there is an obvious luminescence peak in green light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com