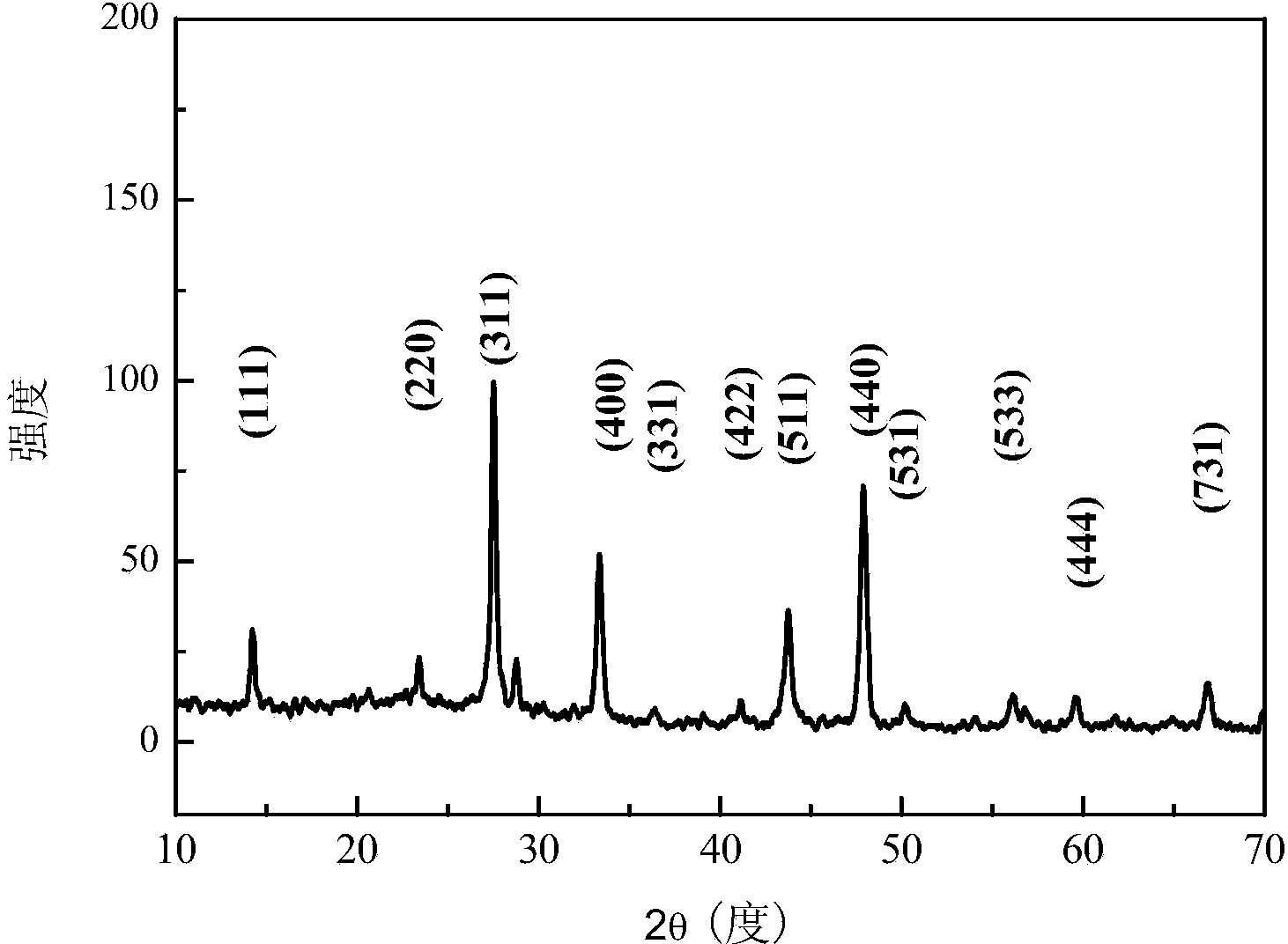

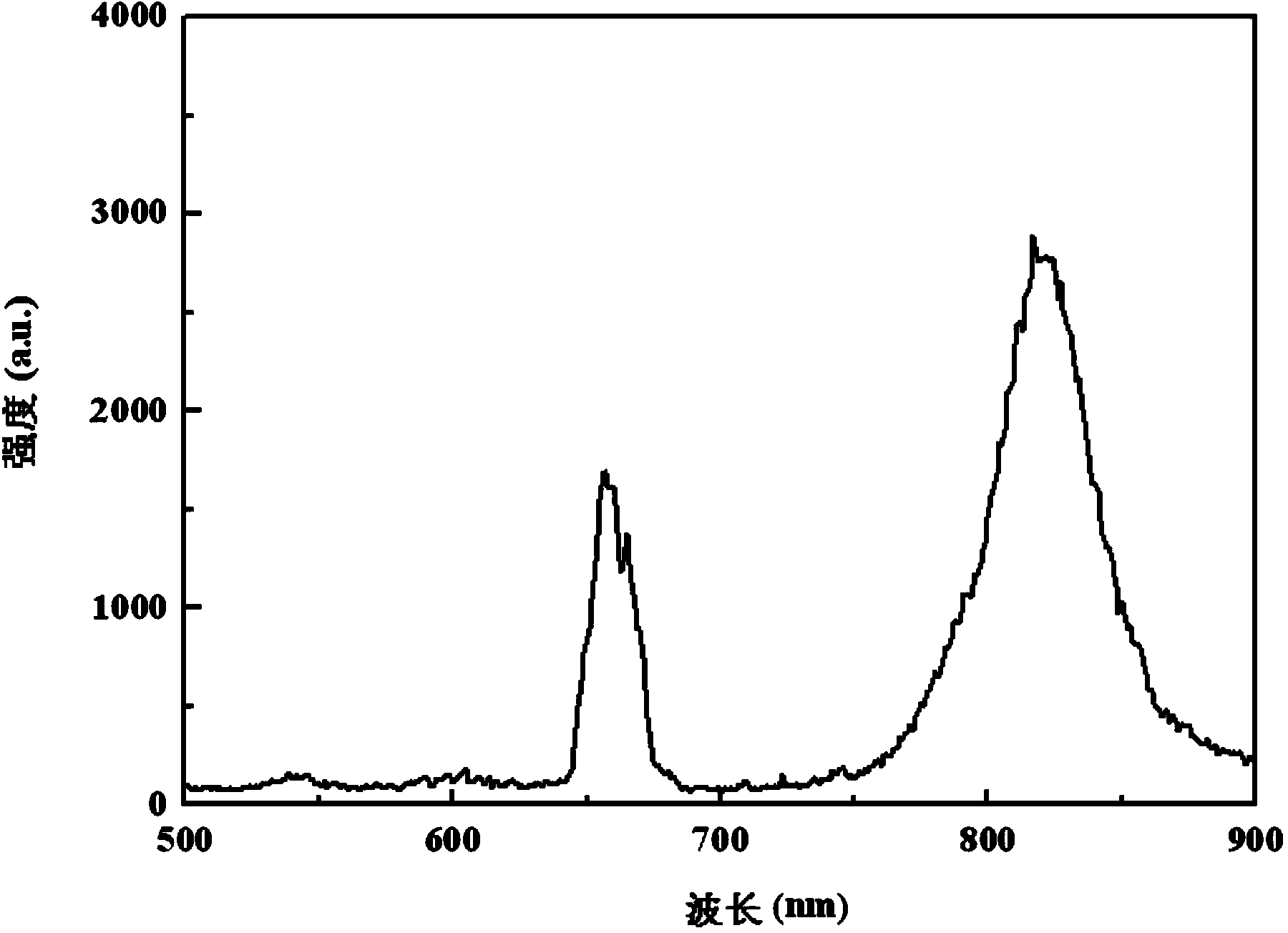

Method for preparing up-conversion red light-emitting indium sulfide

An indium sulfide and red light-emitting technology, which is applied in the field of up-conversion light-emitting, can solve the problems of complex preparation process and high risk, and achieve the effects of simple operation, easy operation and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

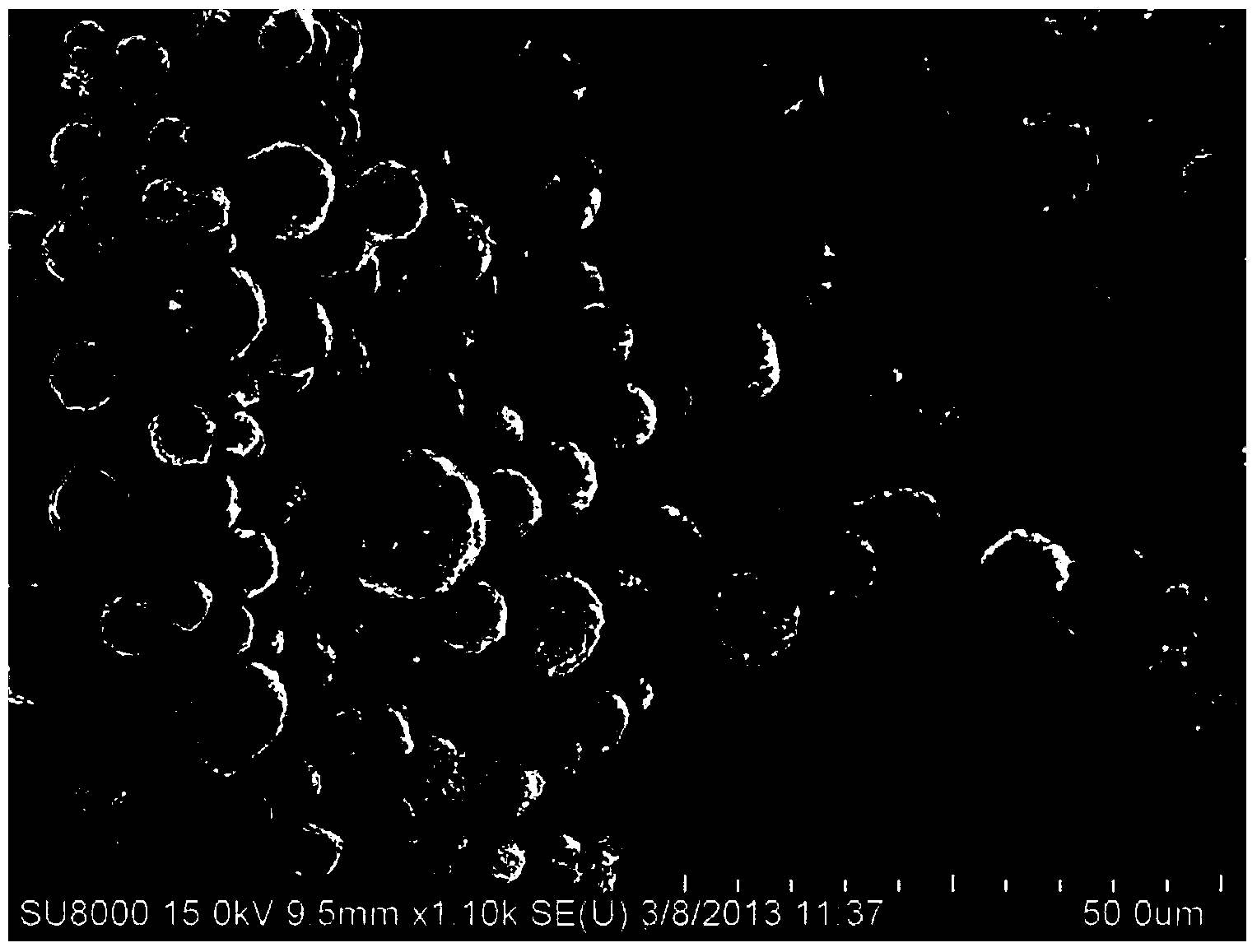

[0017] Specific implementation mode 1: In this implementation mode, a method for preparing up-conversion red-emitting indium sulfide is specifically completed according to the following steps:

[0018] 1. Weigh 75-85 parts of InCl according to the mass parts 3 , 10 to 15 parts of ErCl 3 and 8 to 12 parts of TmCl 3 , simultaneously according to the ratio of the sum of the amount of substance of In, Er and Tm and the amount of substance of thiourea is 1: 1.5, takes by weighing thiourea;

[0019] 2. Weigh the InCl in step 1 3 , ErCl 3 , TmCl 3 and thiourea are packed into a lined polytetrafluoroethylene reactor to obtain a mixed solution;

[0020] 3. Magnetically stir the mixed solution in step 2 for 28-32 minutes, then add deionized water until the filling degree of the reactor reaches 60%, and seal the reactor;

[0021] 4. React the reaction kettle in step 3 at a temperature of 164°C to 166°C for 24 hours, then naturally cool to room temperature, and take out the reactant...

specific Embodiment approach 2

[0024] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, 72 to 74 parts of InCl are weighed according to the number of parts by mass. 3 , 13 to 14 parts of ErCl 3 and 10 parts TmCl 3 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is different from Embodiment 1 in that: in step 3, stir magnetically for 30 minutes. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com