Sweeping roller structure for road maintenance and sweeper

A technology for road maintenance and cleaning rollers, applied in road cleaning, cleaning methods, construction, etc., can solve the problems of increasing operating strength, inconvenient disassembly and assembly, and increasing costs, and achieve the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

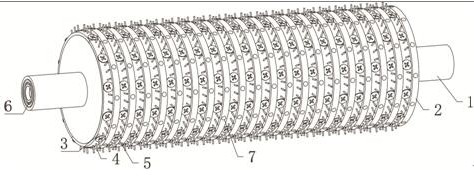

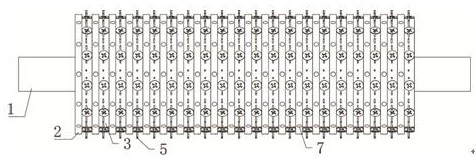

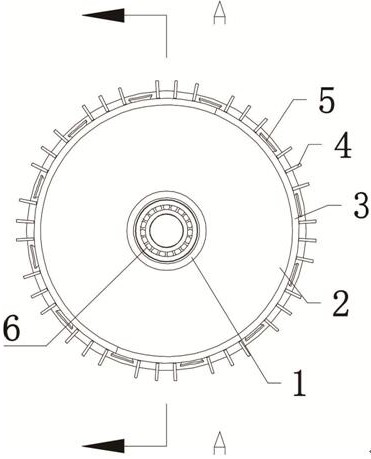

[0034] Reference attached Figure 1~Figure 6 , a cleaning roller for highway maintenance, comprising a cleaning roller body 2 equidistantly provided with a plurality of arc-shaped grooves on the circumferential surface, the cleaning roller body 2 is fixedly mounted on a transmission roller 1, and the transmission roller 1 is a In the shape of a stepped hollow shaft, the cleaning roller body 2 is installed at the maximum diameter of the transmission roller 1, and a plurality of drainage holes 7 pointing to the inside of the transmission roller 1 are provided on the part of the circumference of the cleaning roller body 2 other than the arc groove. Brush mounting plates 3 are movably installed in the arc-shaped grooves of the cleaning roller body 2 through screws 5 respectively, and a plurality of brushes 4 are respectively mounted on the brush mounting plates 3 . Compared with the prior art, the present invention adopts the brush mounting plate which is movably installed on the ...

Embodiment 2

[0043] Reference attached Figure 7 , a cleaning vehicle for road maintenance, including a vehicle body, and also includes the cleaning roller for road maintenance as described in the above embodiments.

[0044] In this embodiment, the car body includes a housing 8, and two groups of driving wheels 9 are installed in parallel at the lower part of the housing 8, and each group of driving wheels 9 is two driving wheels 9 connected coaxially. The lower part of the body 8 is located between the two groups of driving wheels 9, and a cleaning roller body 2 is also installed. The driving roller 1 on the cleaning roller body 2 is installed on the housing 8 through an external bearing, and the driving roller 1 is connected with a belt transmission mechanism 13. The drive shaft of the driving motor 14 fixedly installed on the inner top of the housing 8 maintains the power output.

[0045] In this embodiment, a water tank 10 is fixedly placed on one side of the housing 8, and a garbage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com