Automatic climbing frame adjusting sleeve groove triangle tie structure

An automatic adjustment and triangular bracing technology, which is applied in the direction of building structure support, building structure support, building structure, etc., can solve the problems of unadjustable, weak connection and accident-prone between the climbing frame and the house wall, and achieve the goal of workers Easy to walk, easy to manufacture, easy to disassemble and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

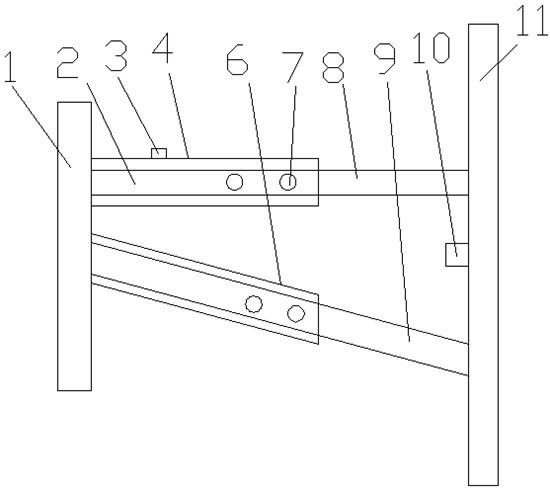

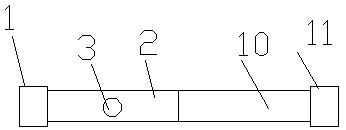

[0033] Embodiment 1, with reference to the accompanying drawings, a fixed sleeve 2, a groove and notch sleeve 6, a fixed core tube 8 and an adjustable core tube 9 are installed between the fixed cylinder base 1 and the adjustment cylinder base 11, and the fixed core cylinder 8 is inserted into the fixed sleeve 2 inner cavity, the radial locking nail 7 passes through the radial locking hole 22 to fix the fixed core tube 8. The radial locking nail 7 fixes the adjusting core barrel 9 through the adjusting locking hole 21 . The bottom surface of groove and notch cylinder 6 is provided with groove and notch 12 for capacity adjustment core cylinder 9 to be loaded into or pulled out of groove and notch cylinder 6,

[0034] And fixed by radial locking nail 7. The fixed cylinder base 1 and the adjusted cylinder base 11 are fixed on the climbing frame and fixed on the room wall by the fixed base nails 10 . The locking nail 3 fixes the fixed core tube 8 in the inner cavity of the fixed...

Embodiment 2

[0035] Embodiment 2, a climbing frame automatic adjustment sleeve groove triangular support structure, including a fixed cylinder base, a fixed sleeve, a locking nail, a top surface of the fixed cylinder base, a radial locking hole, a groove notch cylinder, and a radial locking nail , fixed core barrel, adjusting core barrel, fixing seat nails, adjusting barrel seat, groove gap, inner cavity, fixing seat mounting hole, adjusting seat mounting hole, aisle plate top, through hole, aisle plate bottom surface, aisle plate end surface, aisle Board bottom hook, adjustment lock hole, radial lock hole, fixed lock hole and aisle plate, characterized in that the fixed sleeve 2, the fixed core tube 8, and the groove gap are installed between the fixed cylinder base 1 and the adjustment cylinder base 11 Cylinder 6 and adjusting core tube 9, one end of the fixed core tube 8 is fixedly welded on the inner side of the adjusting tube base 11, the other end of the fixed core tube 8 is inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com