Variable-speed variable-load large rolling bearing fault prediction system and method

A rolling bearing and fault prediction technology, applied in mechanical bearing testing, neural learning methods, biological neural network models, etc., can solve problems such as difficulty in obtaining bearing operating data, large size of faulty bearings, and complex equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

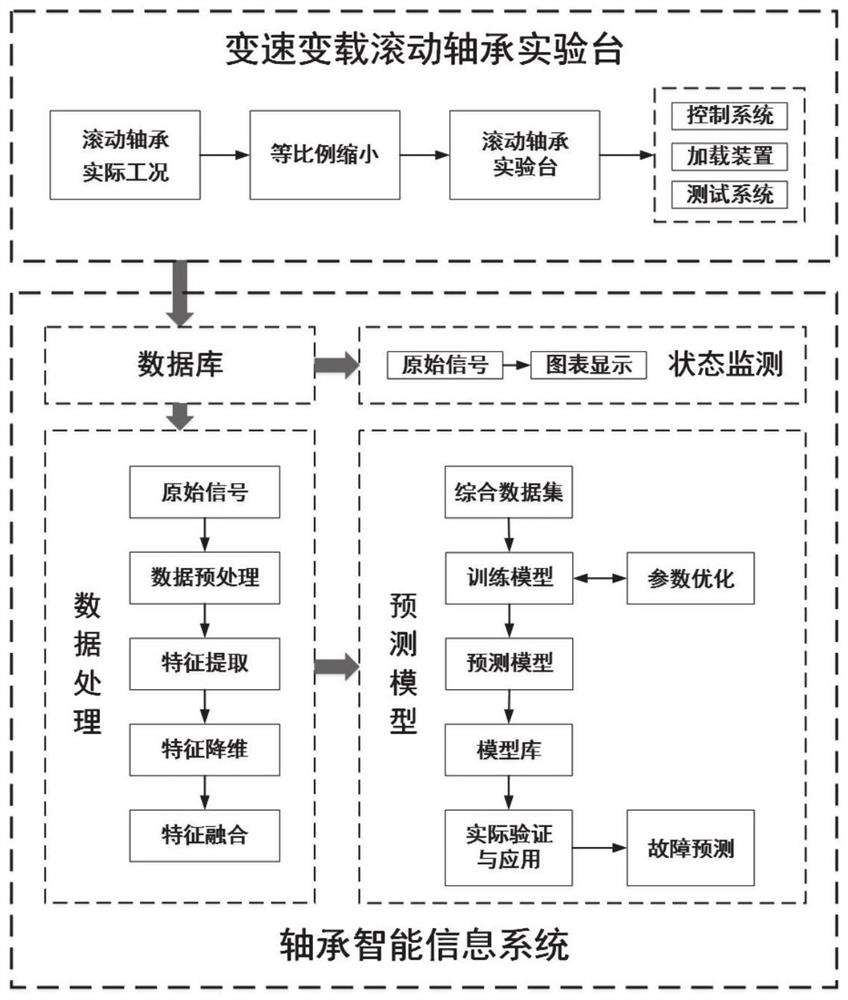

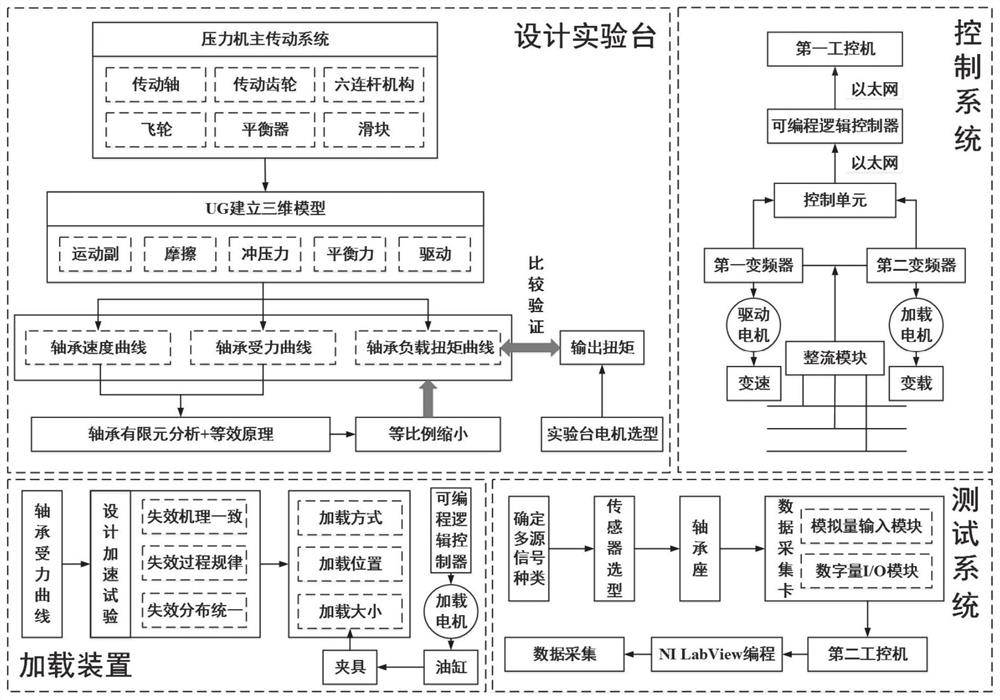

[0035] This embodiment provides a variable speed and variable load large rolling bearing fault prediction system, such as figure 1 As shown, it includes a rolling bearing test bench and a bearing intelligent information system. The rolling bearing test bench is used to simulate the complex working environment of rolling bearings with variable speed and load. It includes a control system, a loading device and a testing system. The testing system is connected to the control system and the loading device.

[0036] Based on the data collected by the rolling bearing test bench, the bearing intelligent information system performs condition monitoring and fault prediction on variable-speed and variable-load large-scale rolling bearings, including a database, a condition monitoring module, a data processing module, and a fault prediction module. The database is connected to the condition monitoring module, and the database Connect the data processing module and the fault prediction mod...

Embodiment 2

[0053] This embodiment provides a method for predicting faults of large-scale rolling bearings with variable speed and variable loads, including: establishing a rolling bearing test bench and installing sensors; storing data collected by the sensors into a database; a data processing module acquiring original signals in the database, and the original signals are passed through The status monitoring module displays; the fault prediction module obtains the comprehensive data set processed by the data processing module, obtains the prediction model through training, and obtains the bearing fault prediction result.

[0054] Further, a rolling bearing test bench is established through three-dimensional software simulation, and relevant speed, torque and load data curves are obtained. The method for setting up the rolling bearing test bench is the same as that of the first embodiment, and will not be repeated here.

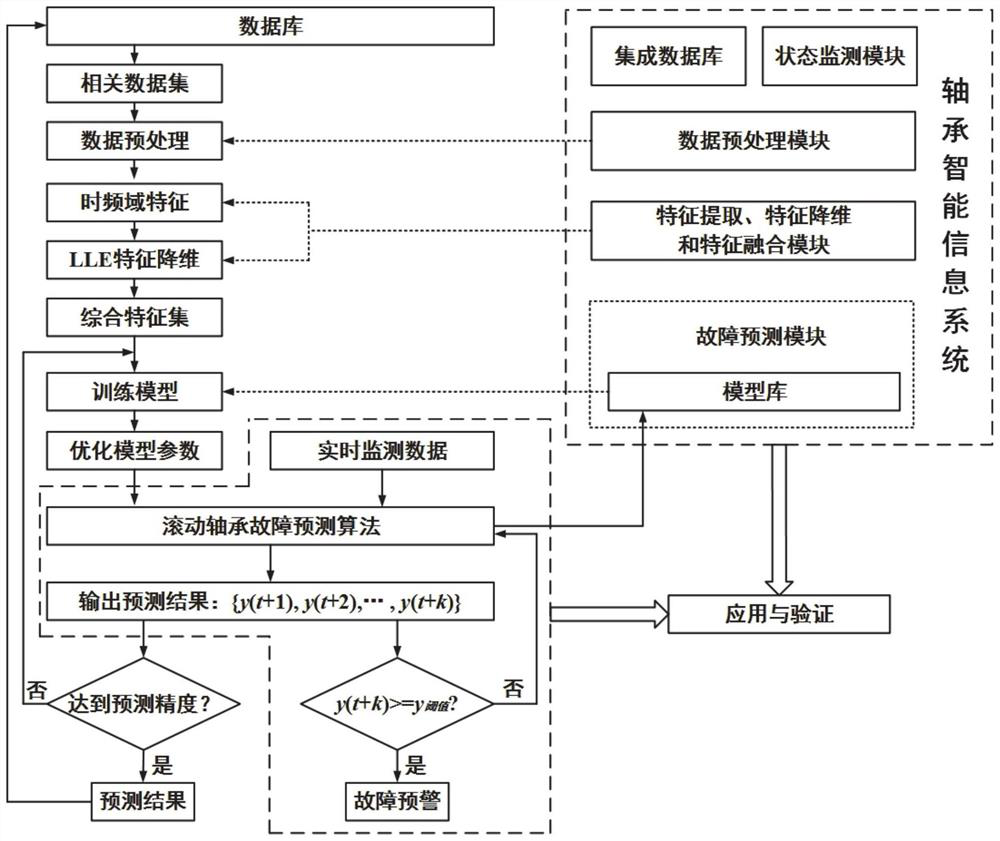

[0055] Such as image 3 As shown, the data in the database is ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com