Method and device for measuring and calculating burning loss rate of dry quenching coke

A technology for dry quenching coke and coke quenching, which is applied in the field of dry quenching, can solve the problems of unfavorable operators in commanding production, reducing the amount of coke burning loss, and having low meaning in regulation, achieving real-time coke burning loss rate and improving Guiding significance, real-time measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to enable those skilled in the art to better understand the technical solution of the present invention, the method and device for measuring the coke loss rate of CDQ provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

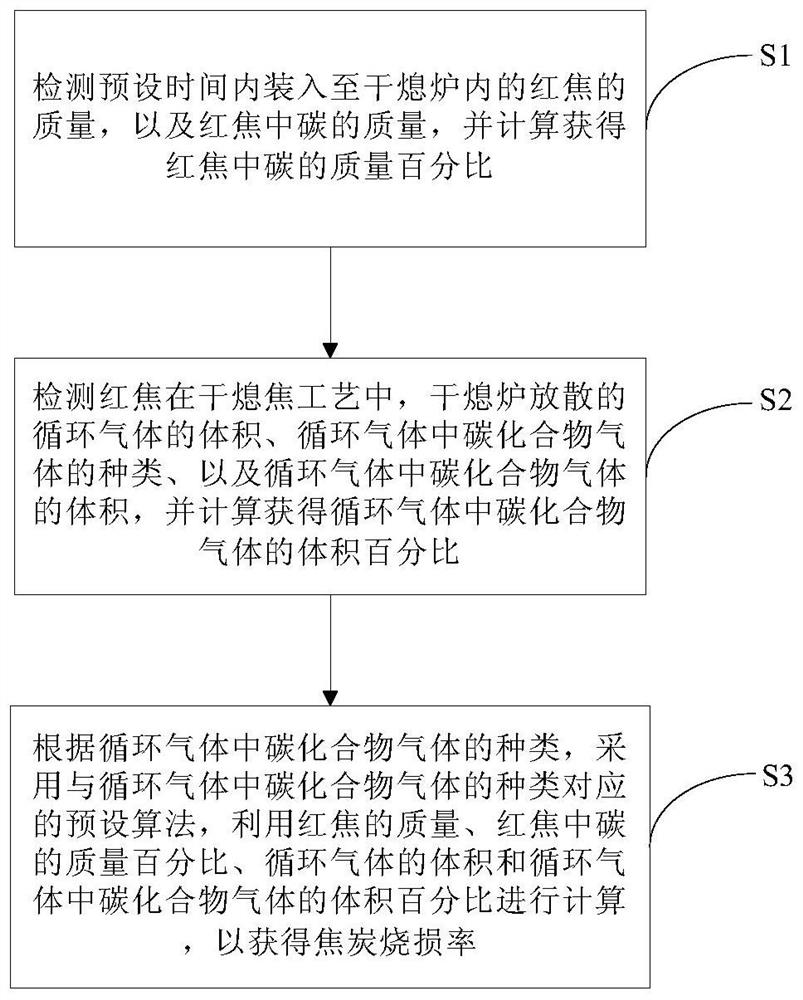

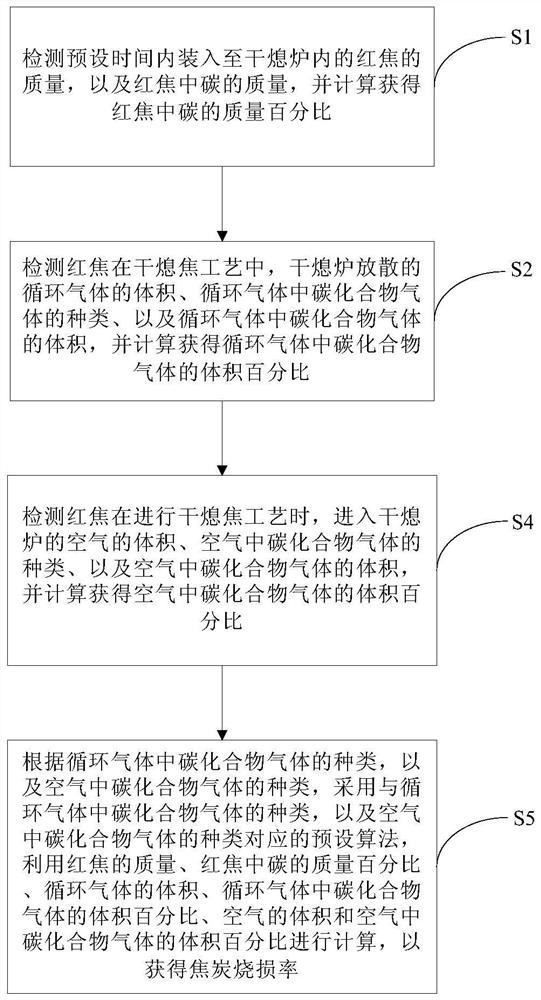

[0053] Such as figure 1 As shown, this embodiment provides a method for calculating the burnout rate of CDQ coke, including the following steps: S1, detecting the quality of red coke loaded into the CDQ furnace within a preset time, and the quality of carbon in the red coke , and calculate the mass percentage of carbon in red coke; S2, detect red coke in CDQ process, the volume of circulating gas released from CDQ furnace, the type of carbon compound gas in circulating gas, and the carbon compound gas in circulating gas volume, and calculate the volume percentage of carbon compound gas in the circulating gas; S3, according to the type of carbon compound gas in the circulating gas, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com