Battery surplus capacity calculating method based on AGV

A battery remaining capacity, trolley technology, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of abnormal control strategy, SOC cannot be estimated accurately in real time, and accumulated errors, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

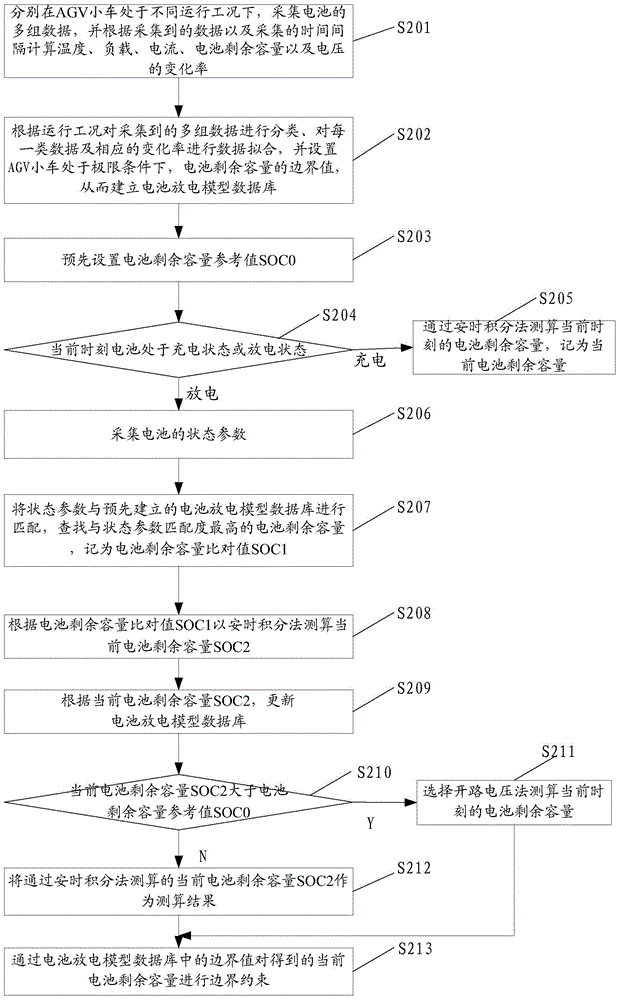

[0032] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

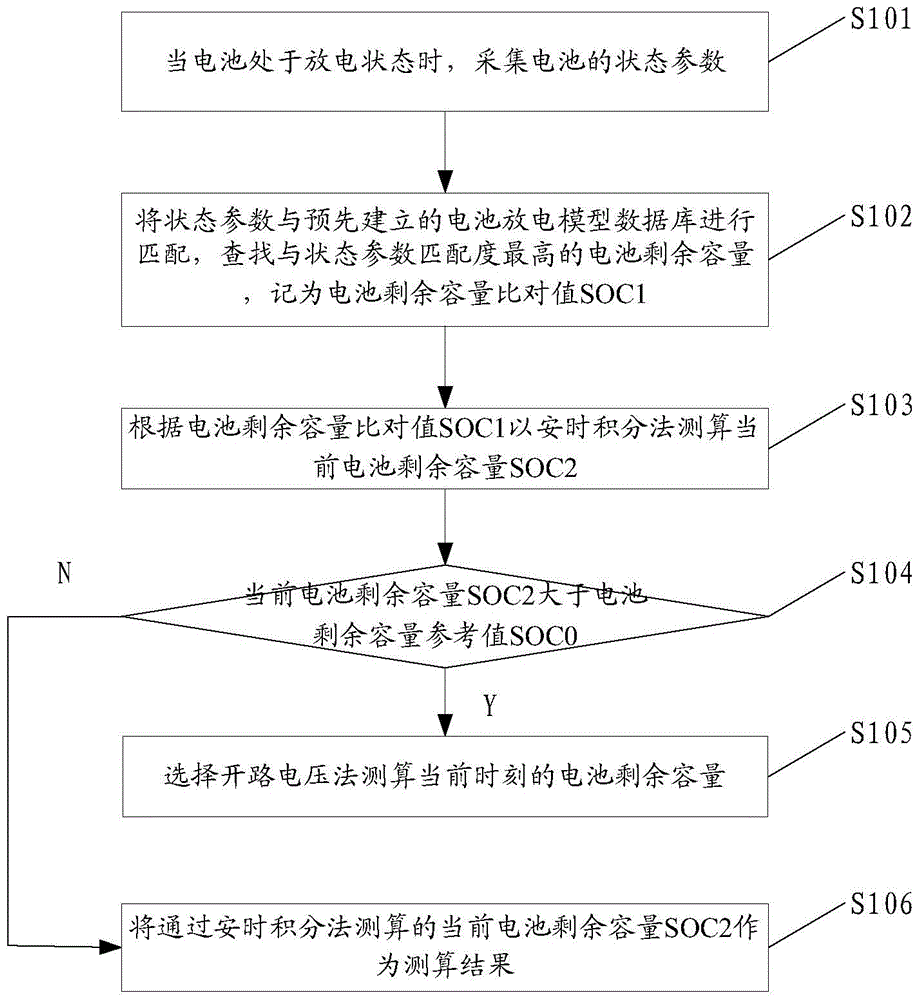

[0033] Please refer to figure 1 , is a flow chart of an embodiment of the method for calculating the remaining battery capacity based on the AGV trolley in the present invention, including the following steps:

[0034] Step S101, when the battery is in the discharge state, collect the state parameters of the battery; wherein the state parameters of the battery include the current temperature, current voltage, current current and the rate of change of the current temperature, current voltage, and current current;

[0035] Step S102, match the state parameters with the pre-established battery discharge model database, find the battery remaining capacity with the highest matching degree with the state parameters, and record it as the battery remaining capacity comparison value SOC1; the battery discharge model database store...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com