Cable production equipment

A technology for producing equipment and cables, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., and can solve problems such as reduced transfer efficiency and laborious transfer of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

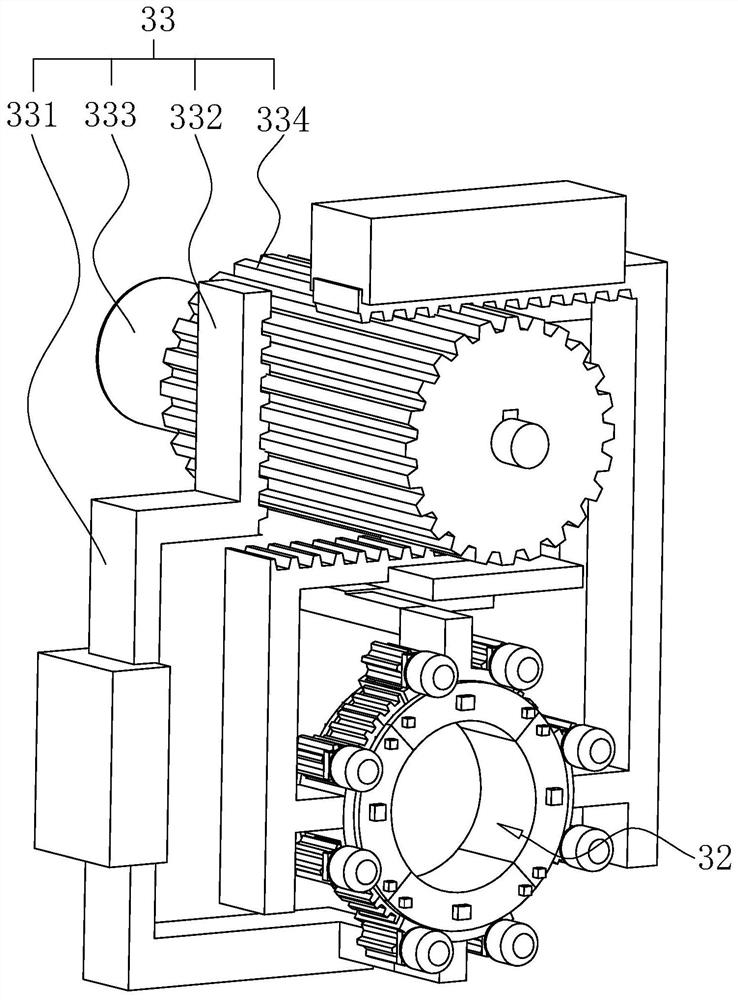

[0040] The following is attached Figure 1-10 The application is further described in detail: the packaging device 1 is an injection molding machine, the drying device 4 is an oven, and all motors are three-phase asynchronous motors.

[0041] refer to figure 1 , discloses a cable production equipment for the embodiment of the present application, including a packaging device 1 , a limiting device 6 , a cooling device 2 , a wiping mechanism 3 , a drying device 4 , a limiting device 6 and a winding device 5 in the cable processing direction.

[0042] The limiting device 6 includes a limiting frame 61 on which a rotating roller 62 is rotatably connected.

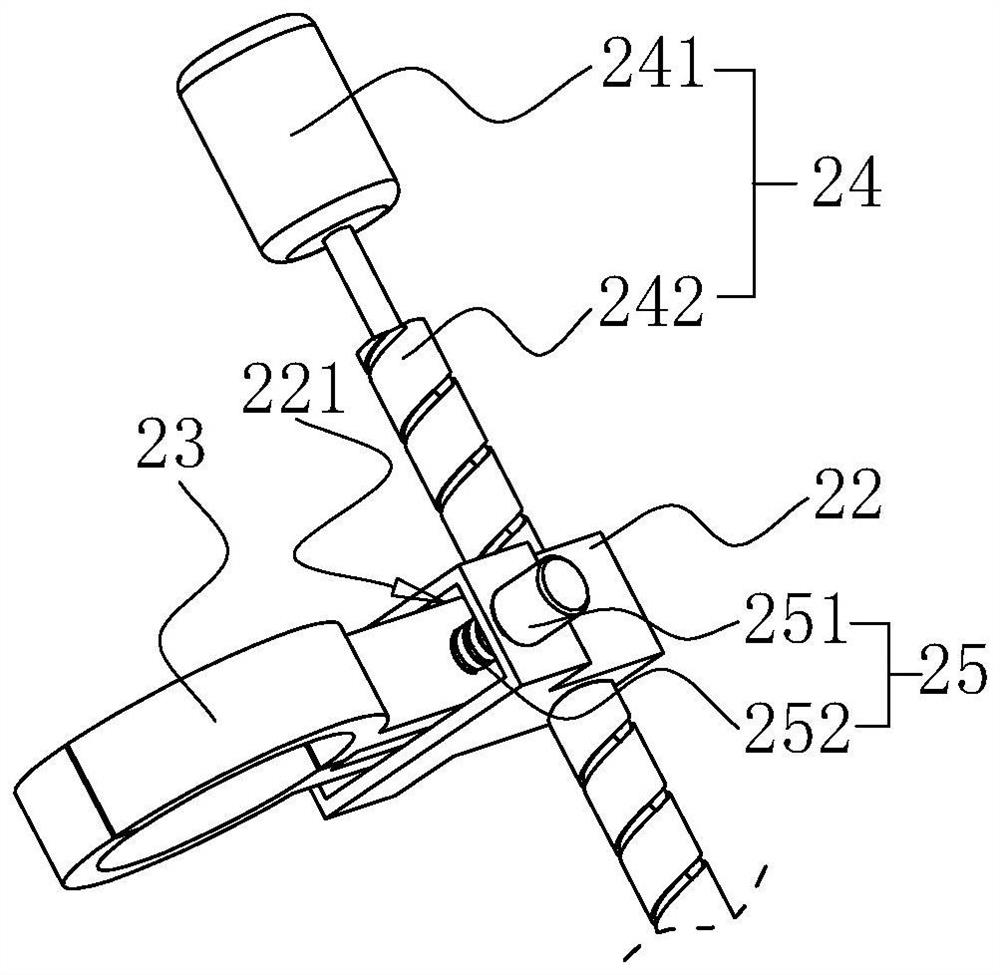

[0043] refer to figure 1 and figure 2 , the cooling device 2 includes a cooling pool 21, the two ends of the cooling pool 21 are respectively a feed end and a discharge end, the cooling pool 21 is provided with a seventh chute, and the seventh chute is connected with a transfer block 22 for sliding. The pool 21 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com