Measuring system and method for determining a force and/or a torque on a torque-transmitting shaft

A measurement system, torque transmission technology, applied in force/torque/power measuring instrument, measurement of property force of piezoelectric device, force sensor related to bearing, etc., can solve problems such as long response time, and achieve accurate determination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

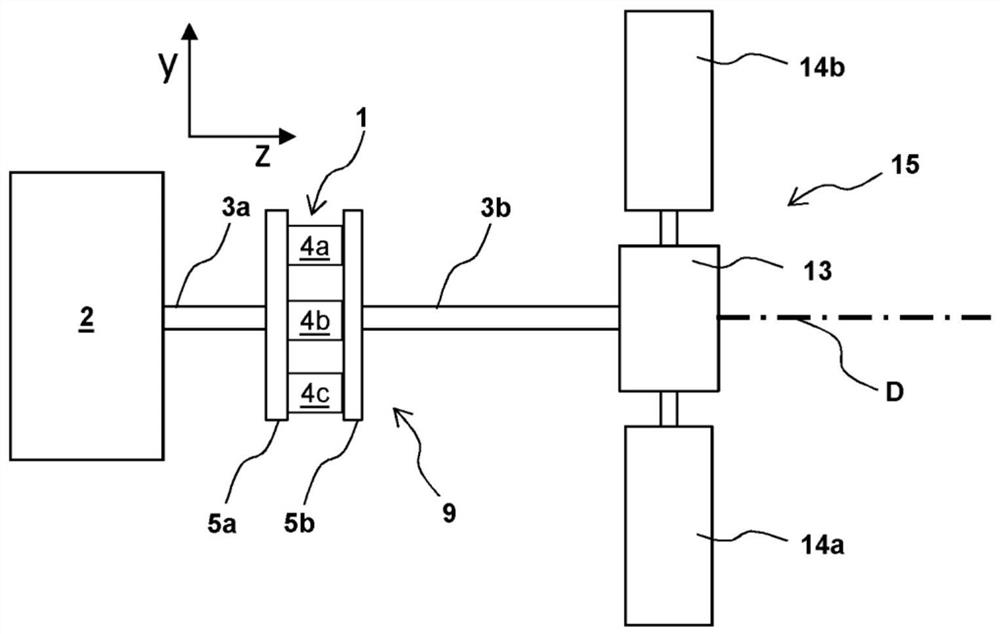

[0106] figure 1 A top view of a first exemplary embodiment of a measuring assembly 9 for determining forces and / or torques on torque-transmitting shafts 3 a , 3 b on a drive test stand 15 is shown. The shafts 3a, 3b in this case connect the motor 2, which is mainly used as a bearing device for the shafts 3a, 3b, to a transmission and a differential 13, which in turn are connected via shaft sections to the wheel gauges. The force gauges 14a, 14b are connected.

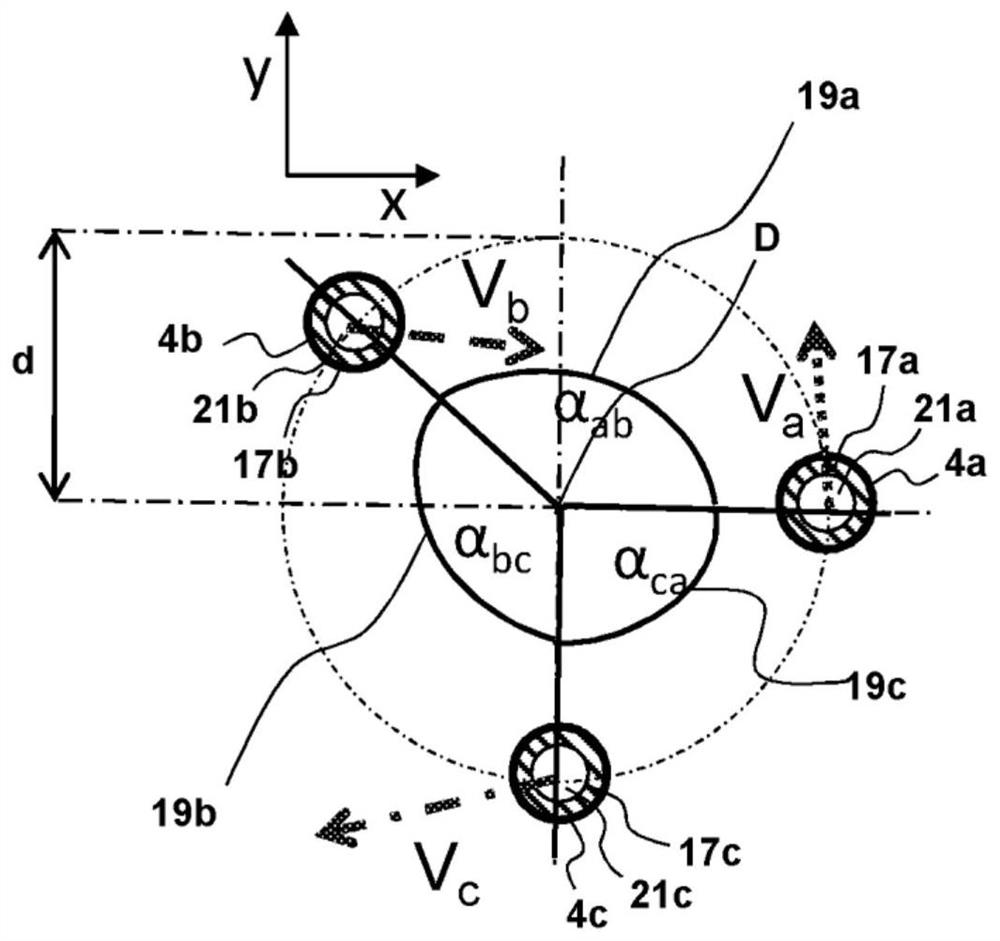

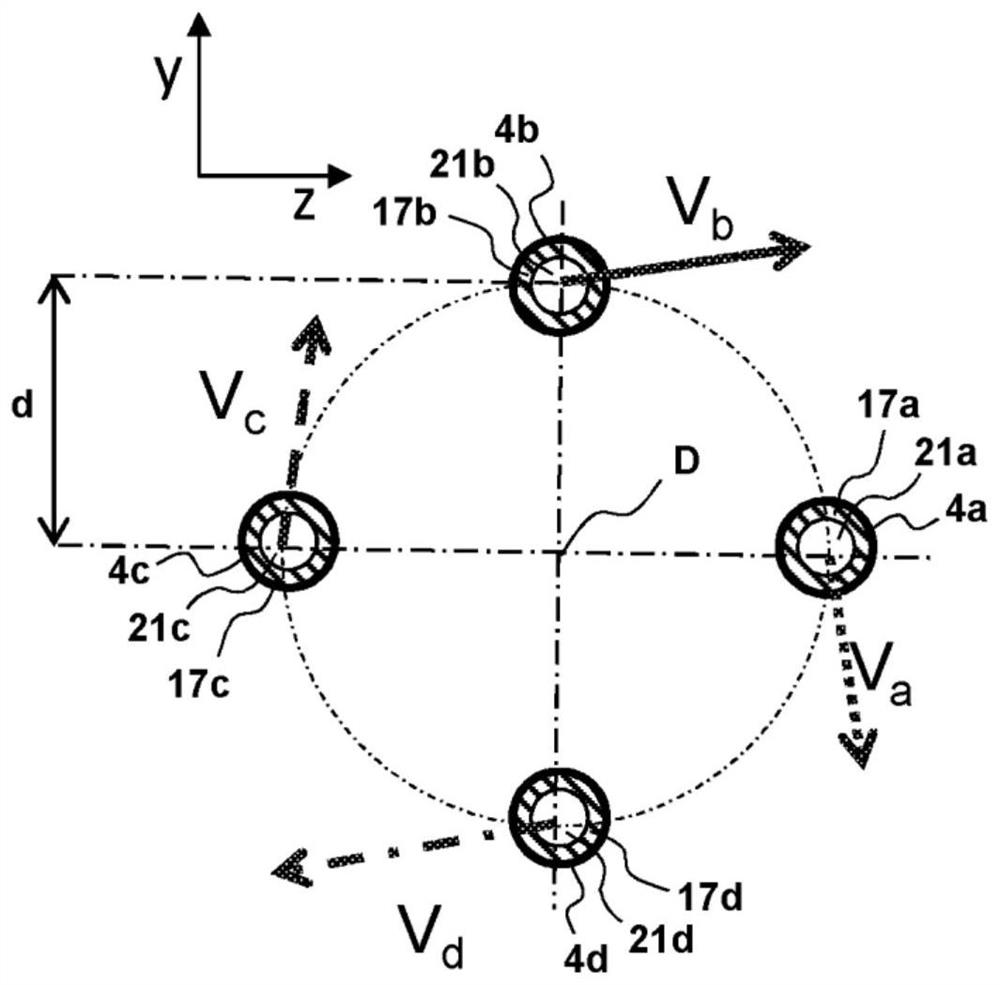

[0107] Between the first section 3 a of the shaft and the second section 3 b of the shaft is arranged a measuring system 1 which has a two-part measuring flange 5 a , 5 c as a fastening device. The first section 3a of the shaft is connected in a rotationally fixed manner to the first part 5a of the measuring flange, and the second section 3b of the shaft is connected in a rotationally fixed manner to the second part 5b of the measuring flange. The three piezoelectric elements 4 a , 4 b , 4 c are arranged between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com