Patterned vamp and preparation method thereof

A vamp and pattern technology, applied to soles, uppers, footwear, etc., can solve problems such as low fit, low stability, and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

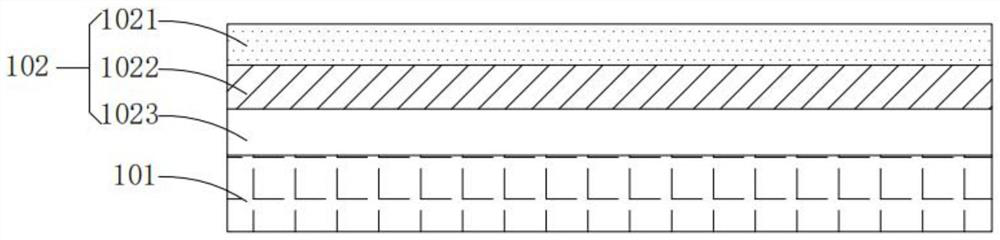

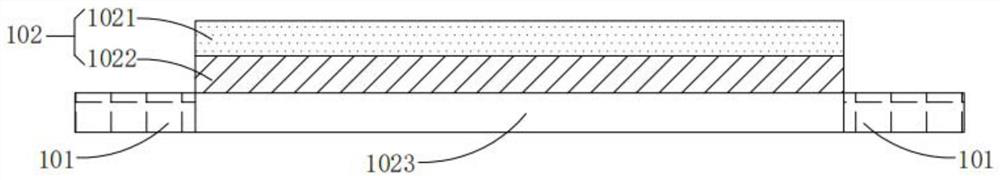

[0110] See figure 1 , a patterned vamp, comprising a vamp body 101 and a transparent part 102 connected to the vamp body 101, the transparent part 102 comprising a transparent surface layer 1021 and a pattern layer arranged on the lower surface of the transparent surface layer 1021 1022 ; the pattern layer 1022 is a plant.

[0111] The preparation method of the transparent member 102 includes the following steps:

[0112] The transparent rubber material is placed in the mold cavity, the plants are put in, and the cover mold is formed.

[0113] Concrete preparation method comprises as follows:

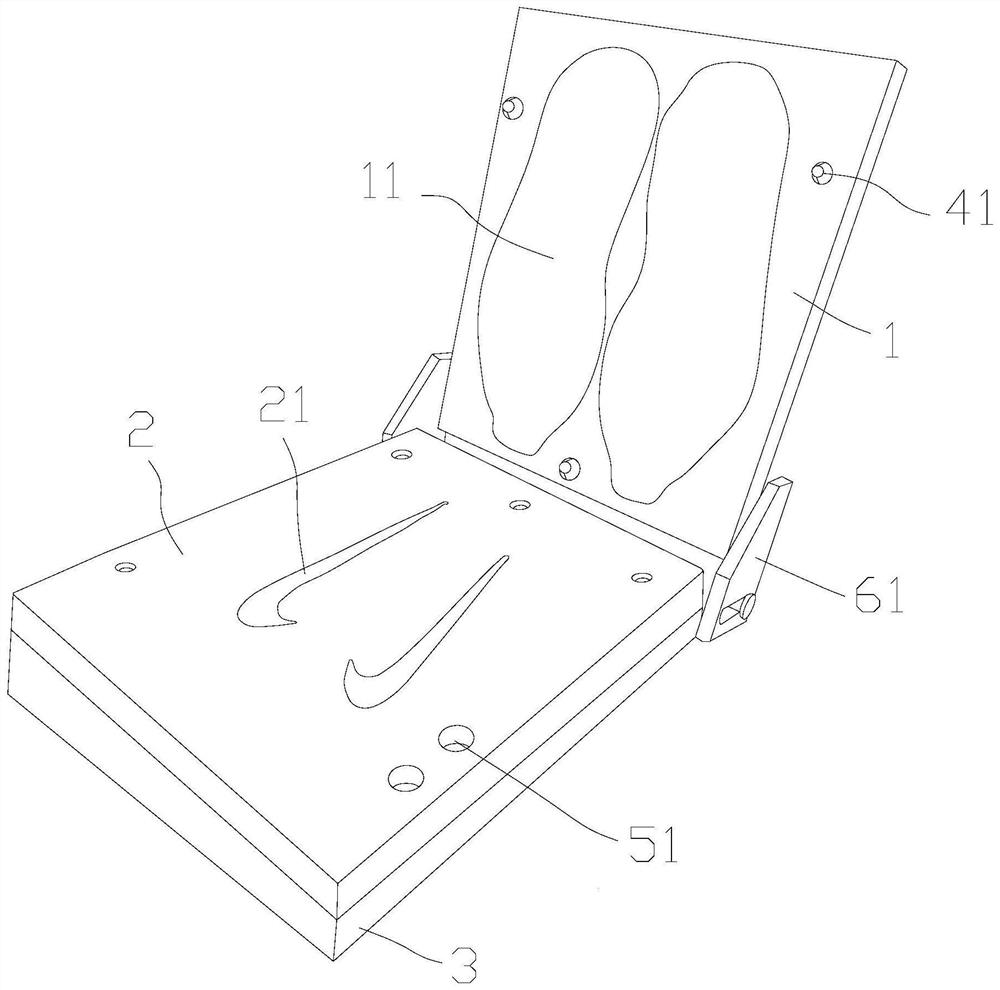

[0114] Described mold cavity comprises upper mold 1, middle mold 2 and lower mold 3, and the top of described lower mold 3 is provided with the molding cavity 31 that is used to place transparent rubber material; The bottom of the mold 1 is provided with a molding surface 11 corresponding to the molding cavity 31;

[0115] Operation: Put the transparent rubber material in the moldi...

Embodiment 2

[0118] See figure 1 , a patterned vamp, comprising a vamp body 101 and a transparent part 102 connected to the vamp body 101, the transparent part 102 comprising a transparent surface layer 1021 and a pattern layer arranged on the lower surface of the transparent surface layer 1021 1022 ; the pattern layer 1022 is a plant.

[0119] The preparation method of the transparent member 102 includes the following steps:

[0120] The transparent rubber material is placed in the mold cavity, the plants are put in, and the cover mold is formed.

[0121] Concrete preparation method comprises as follows:

[0122] The mold cavity includes an upper mold 1 and a lower mold 3, the top of the lower mold 3 is provided with a molding cavity 31 for placing transparent rubber materials, and the bottom of the upper mold 1 is provided with a molding surface 11 corresponding to the molding cavity 31 ;

[0123] Operation: Place the transparent rubber material in the molding cavity 31 of the lower...

Embodiment 3

[0126] See figure 1 , a patterned vamp, comprising a vamp body 101 and a transparent part 102 connected to the vamp body 101, the transparent part 102 comprising a transparent surface layer 1021 and a pattern layer arranged on the lower surface of the transparent surface layer 1021 1022 ; the pattern layer 1022 is a plant.

[0127] The preparation method of the transparent member 102 includes the following steps:

[0128] The transparent rubber material is placed in the mold cavity, the plants are put in, and the cover mold is formed.

[0129] Concrete preparation method comprises as follows:

[0130] The mold cavity includes an upper mold 1 and a lower mold 3, the top of the lower mold 3 is provided with a molding cavity 31 for placing transparent rubber materials, and the bottom of the upper mold 1 is provided with a molding surface 11 corresponding to the molding cavity 31 ;

[0131] Operation: Place the transparent rubber material in the molding cavity 31 of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com